Resonant orifice type electronically controlled fuel injector

An electronically controlled fuel injection and fuel injector technology, which is applied to fuel injection devices, machines/engines, and charging systems, can solve the problems of large dynamic oil return and energy loss, reduce fuel pressure fluctuations, improve Effect of pressure fluctuation and economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

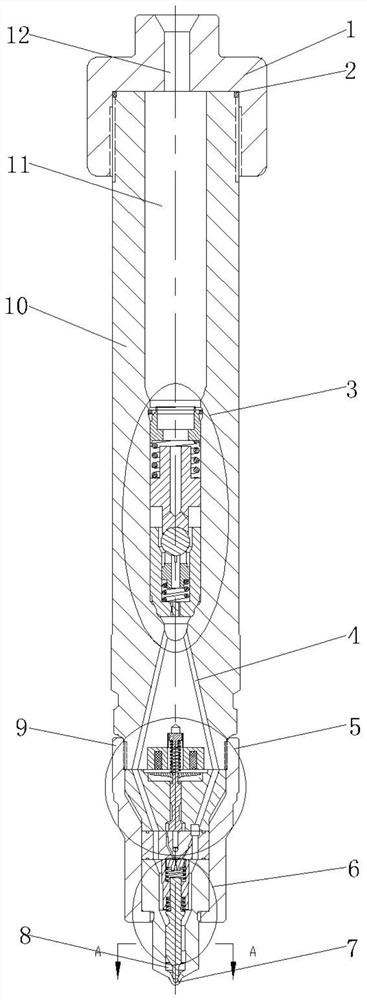

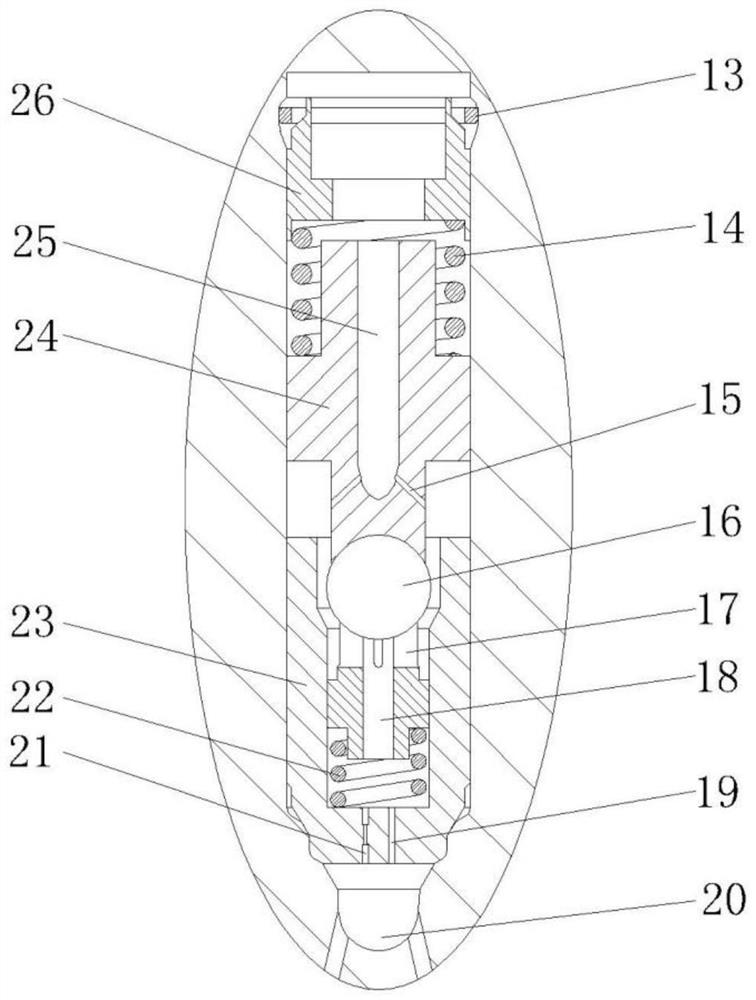

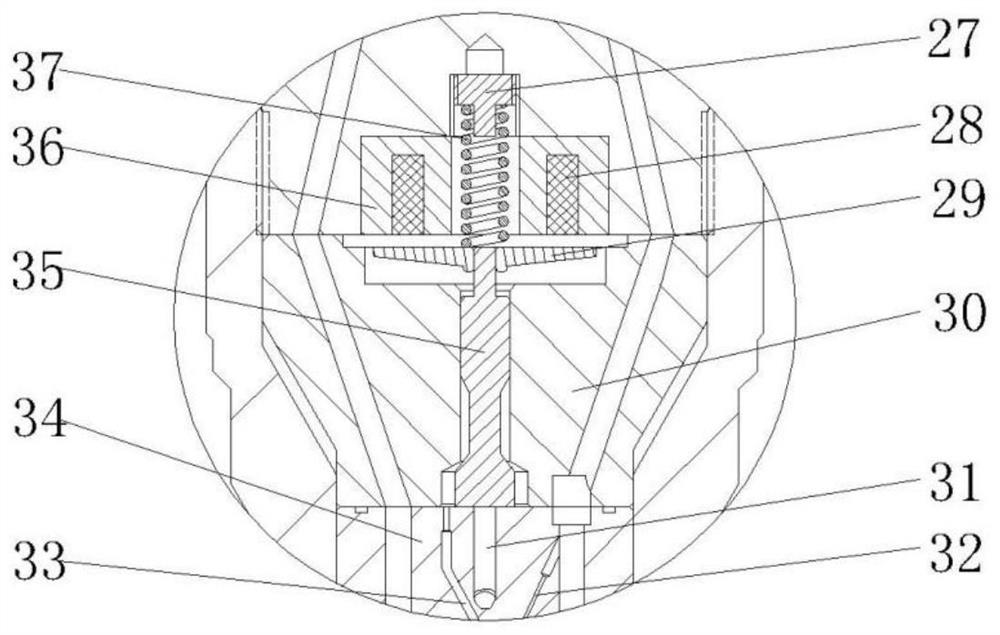

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings:

[0022] combine Figure 1-5 , The present invention includes an injector head 1 , a restrictor valve assembly 3 , a solenoid valve assembly 5 , a needle valve assembly 6 , a tight cap 9 , and an injector body 10 . The fuel injector head 1 is mounted on the fuel injector body 10 through a fitting connection with threads, and is sealed by a sealing ring 2 placed on the fuel injector body 10 . A main oil inlet hole 12 is provided in the injector head 1 and communicates with the pressure accumulating chamber 11 in the injector body 10 . A restrictor valve assembly 3 is provided below the pressure accumulating chamber 11 . The restrictor valve assembly 3 is installed inside the injector body 10, and its main structure includes a retaining ring 13, a damping spring 14, a ball valve 16, a support control slider 17, a ball valve return spring 22, a ball valve return sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com