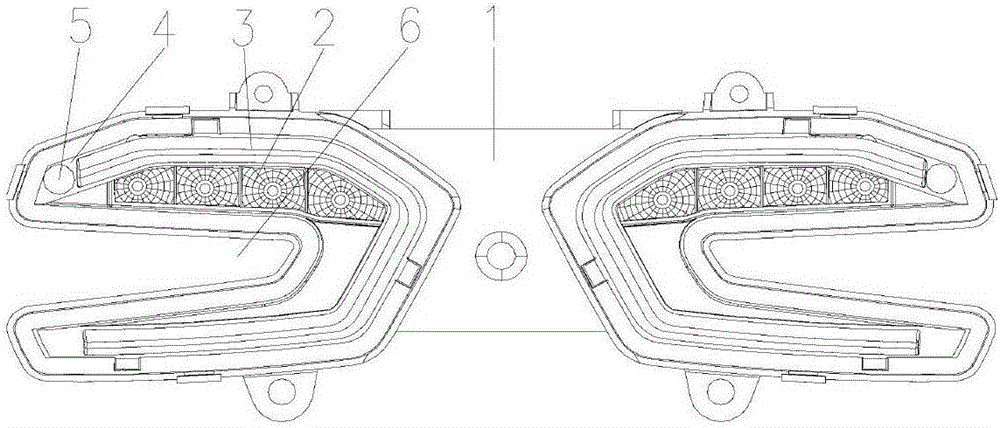

Motorcycle tail lamp assembly mechanism

A technology for motorcycles and taillights, applied in motor vehicles, road vehicles, machinery and equipment, etc., can solve the problems of lamp interior space, energy consumption product cost limitation, high heat generation, and achieve beautiful appearance, reduce manufacturing costs, and energy consumption. and calorific reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Such as figure 1 As shown, a motorcycle tail light assembly mechanism provided by the present invention includes a tail light housing 1 fixedly arranged at the rear of the motorcycle, a brake light 2 fixedly arranged at the tail light housing 1 and a brake light 2 fixedly arranged at the tail light The position light assembly of the housing; the position light assembly includes a light-emitting part 5 and a light-guiding part 3 for guiding the light emitted by the light-emitting part 5; a motorcycle taillight assembly mechanism of the present invention, through LED The position light assembly formed by the lamp bead and the light guide can guide and diverge the light through the light guide. Only one LED lamp can be installed in each installation groove to meet the lighting effect, reducing the number of LED lamp beads or bulbs installed. Realize effective reduction of energy consumption and calorific value, effectively prolong the service life of the taillight, reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com