Steam generator using solar thermal power generation

A steam generating device and a technology for solar thermal power generation, applied in the field of solar power generation, can solve the problems of heat transfer loss, reduce the power generation efficiency of a heat engine, etc., and achieve the effects of improving efficiency, improving efflux efficiency, and speeding up discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

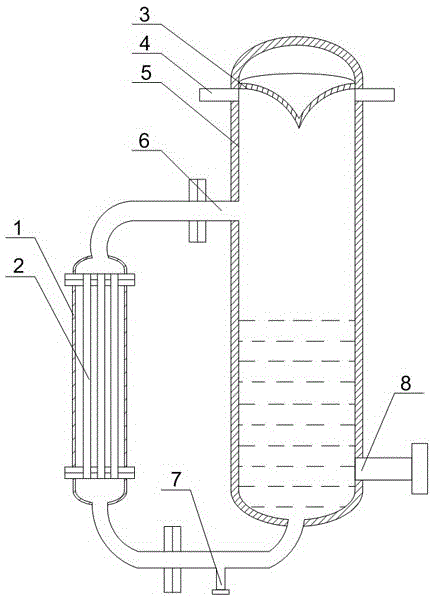

[0020] Such as figure 1 As shown, the present embodiment includes a tank body 5 and a solar external heat pipe 1, the bottom of the tank body 5 communicates with the bottom of the solar external heat pipe 1 through a conduit, and the middle part of the tank body 5 communicates with the top of the solar external heat pipe 1 through a conduit. A liquid inlet 8 is opened on the side wall of the tank body 5, and two mutually symmetrical gas outlets 4 are opened on the top side wall of the tank body 5, and a deflector 3 is fixed on the top of the tank body 5, The middle part of the deflector 3 protrudes downwards to form an inverted cone, and the outer cone surface of the inverted cone is bent inward along its center line, and the axis of the air outlet 4 is right on the curved outer cone surface, and also It includes a plurality of solar inner heat pipes 2, and the solar inner heat pipes 2 are fixed in the solar outer heat pipe 1 through flanges.

[0021] When the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com