Chemical process failure detection method based on failure-dependent principal component space

A fault detection and chemical process technology, which is applied in the field of chemical process fault detection based on the fault-related principal component space, can solve the problems of redundancy, low fault detection efficiency and accuracy, and insensitivity to faults. The effect of industrial production safety and redundancy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

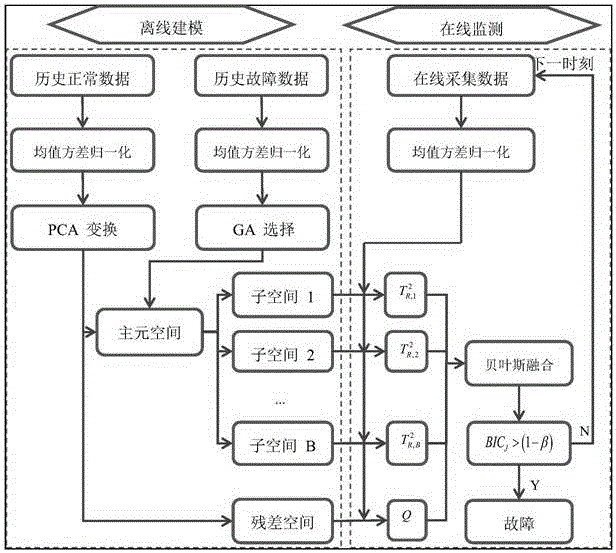

[0050] Such as figure 1 As shown, a kind of chemical process fault detection method based on the fault-related principal component space proposed by the present invention comprises the following steps:

[0051] Step 1. Based on historical data under normal conditions, PCA is used to construct the principal component space and residual space.

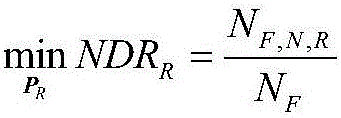

[0052] Suppose the data matrix can be expressed as X∈R n×m, n is the number of historical normal data, m is the number of observed variables; normalize the mean variance of the historical normal data, that is, each data subtracts its respective mean value, and then divides it by its respective variance; through PCA, the data matrix X is decomposed into the sum of the outer products of m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com