Finite element calculating method of shear deformation force of well casing

A technology of drilling casing and shear deformation, which is applied in the field of drilling and oil production, can solve the problems of costing a lot of material and financial resources, the limit of maximum shear load, and the limitation of test specifications, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

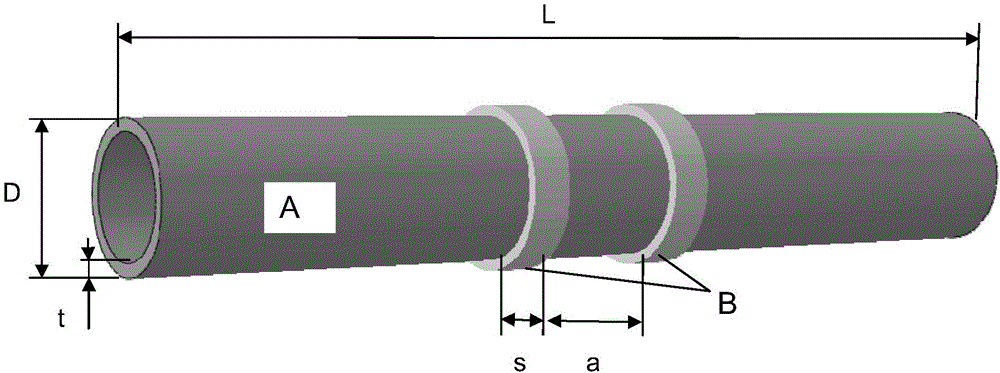

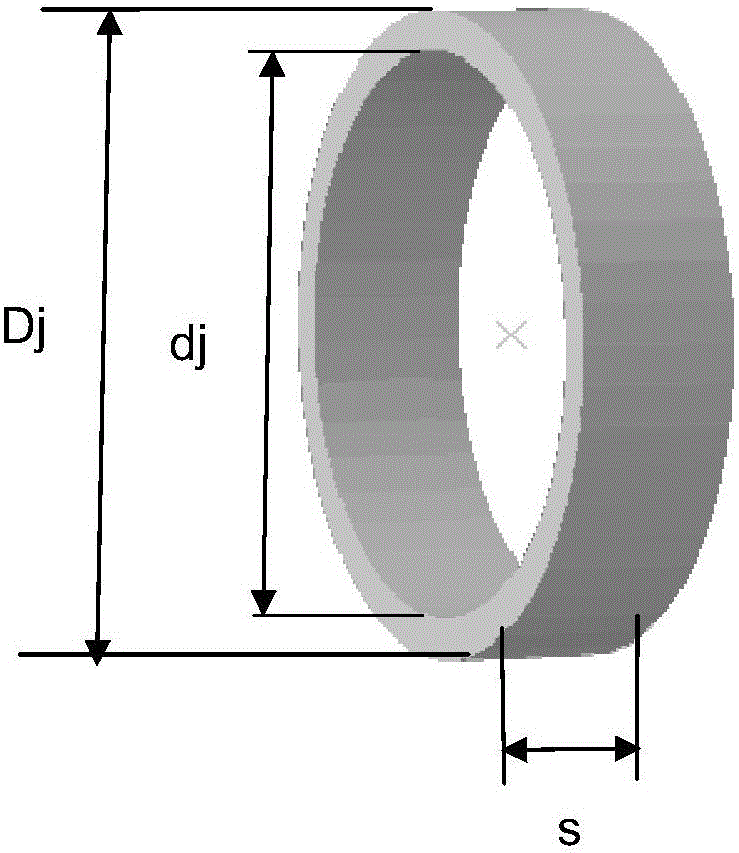

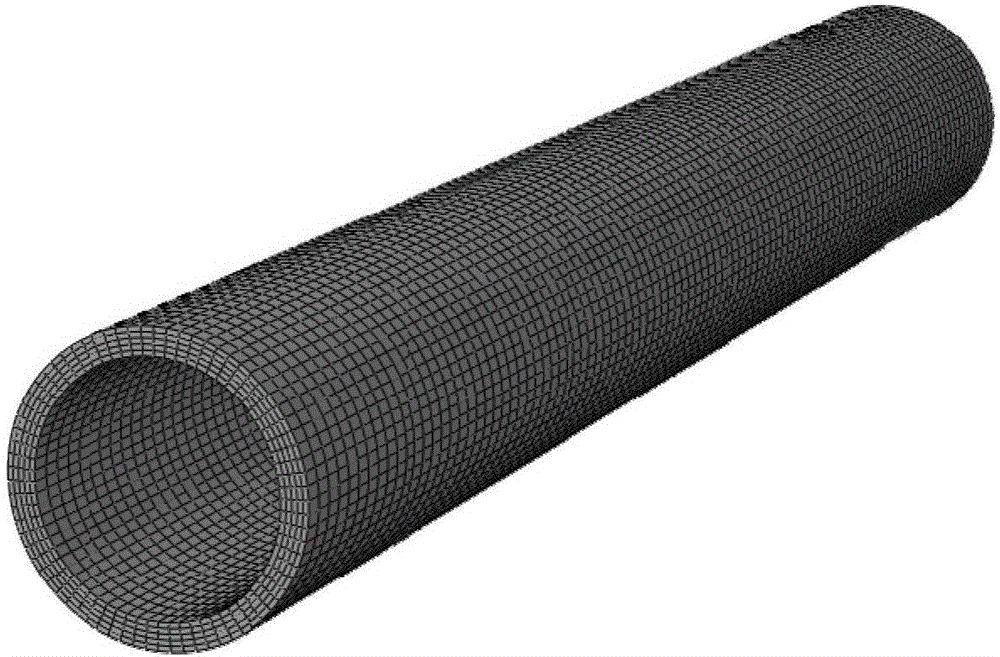

[0042] Casing specification outer diameter D=139.7mm, wall thickness t=12.7mm, steel grade Q125, elastic modulus E=206GPa, Poisson’s ratio μ=0.3, yield strength σ S =862~1034MPa, tensile strength σ b >931MPa. Modeling is carried out according to the above-mentioned finite element calculation method, the length of the pipe body is 1000mm, the width of the two shear rings is s=40mm, and the distance a=127mm. Figure 4 It is the relationship diagram between the shear force and the moving distance of the shear ring extracted by the finite element software, and the maximum value of the shear force before the sudden change can be obtained as 1625KN, so this value is the maximum shear force that the casing can withstand.

Embodiment 2

[0044] Casing specification outer diameter D=146.7mm, wall thickness t=15.9mm, steel grade TP140V, elastic modulus E=206GPa, Poisson’s ratio μ=0.3, yield strength σ S =985~1080MPa, tensile strength σ b >1034MPa. Modeling is carried out according to the above-mentioned finite element calculation method, the length of the pipe body is 1000mm, the width of the two shear rings is s=40mm, and the distance a=127mm. Through the finite element software, the maximum value of the shear force before the sudden change can be obtained as 2405KN, so this value is the maximum shear force that the casing can withstand.

Embodiment 3

[0046]Casing specification outer diameter D=177.8mm, wall thickness t=10.36mm, steel grade P110, elastic modulus E=206GPa, Poisson’s ratio μ=0.3, yield strength σ S =758~965MPa, tensile strength σ b >862MPa. Modeling is carried out according to the above-mentioned finite element calculation method, the length of the pipe body is 1000 mm, the width of the two shear rings is s=50 mm, and the distance a=127 mm. Through the finite element software, the maximum value of the shear force before the sudden change can be obtained as 1454KN, so this value is the maximum shear force that the casing can withstand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com