A fuel assembly that can be used for integrated refueling

A fuel assembly and fuel element technology, applied in the field of nuclear reactors, can solve problems such as unstable mechanical fixation, inability to complete installation, and low assembly density, so as to improve service safety, reduce flow-induced vibration, and reduce charge volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

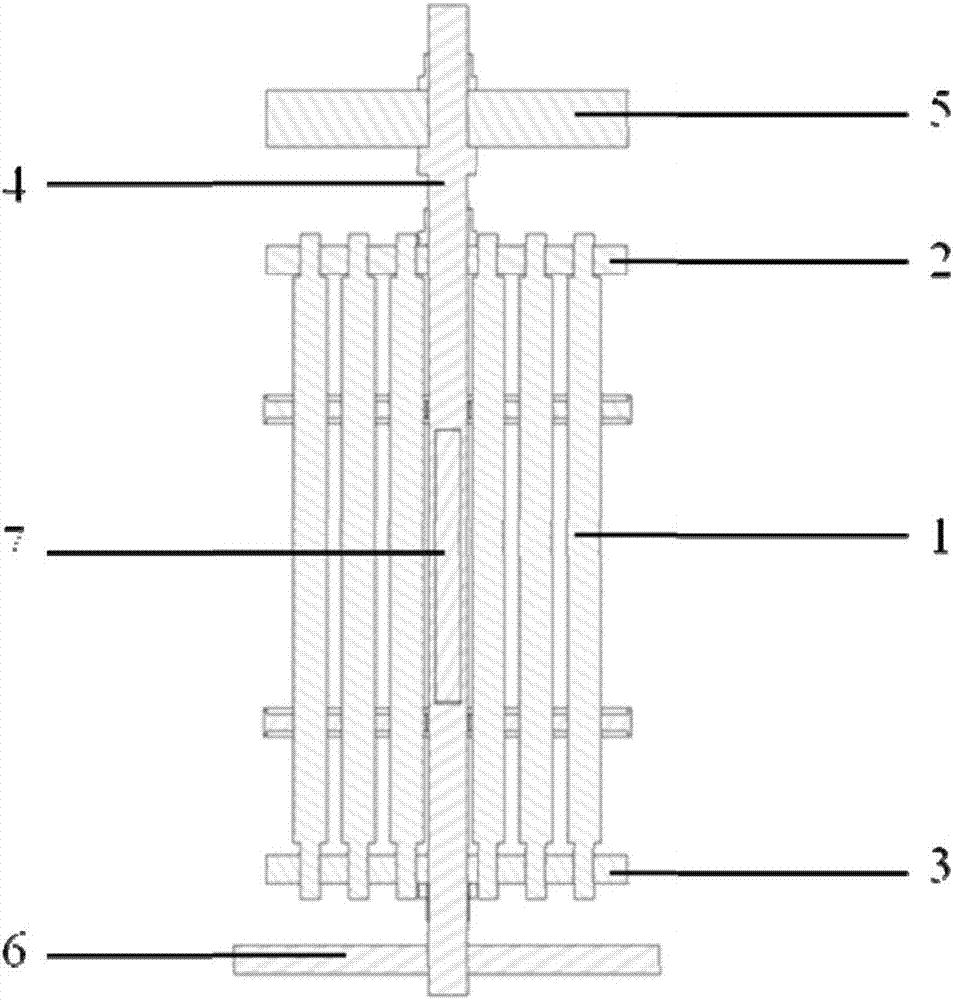

[0020] refer to figure 1 , the structural features of the present invention are described in detail as follows:

[0021] A fuel assembly that can be used for integrated refueling, which is assembled from a certain number of fuel elements 1, upper nozzles 2, lower nozzles 3, and fixing rods 4 to form an integral structure; the integrated refueling fuel assembly is fixed by a top cover, and the fuel The element 1 is fixed at the upper end and free at the lower end; several fixing rods 4 are distributed inside the fuel assembly, the upper ends of the fixing rods 4 are directly fixed on the reactor top cover 5, and the lower ends of the fixing rods 1 are inserted into the reactor core support grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com