High-power single-motor three-position operating mechanism

An operating mechanism, a single motor technology, applied in the contact drive mechanism, the power device inside the switch, etc., can solve the problems of complex structure and assembly, small output torque, high process performance, save volume, reduce friction loss, The effect of preventing malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

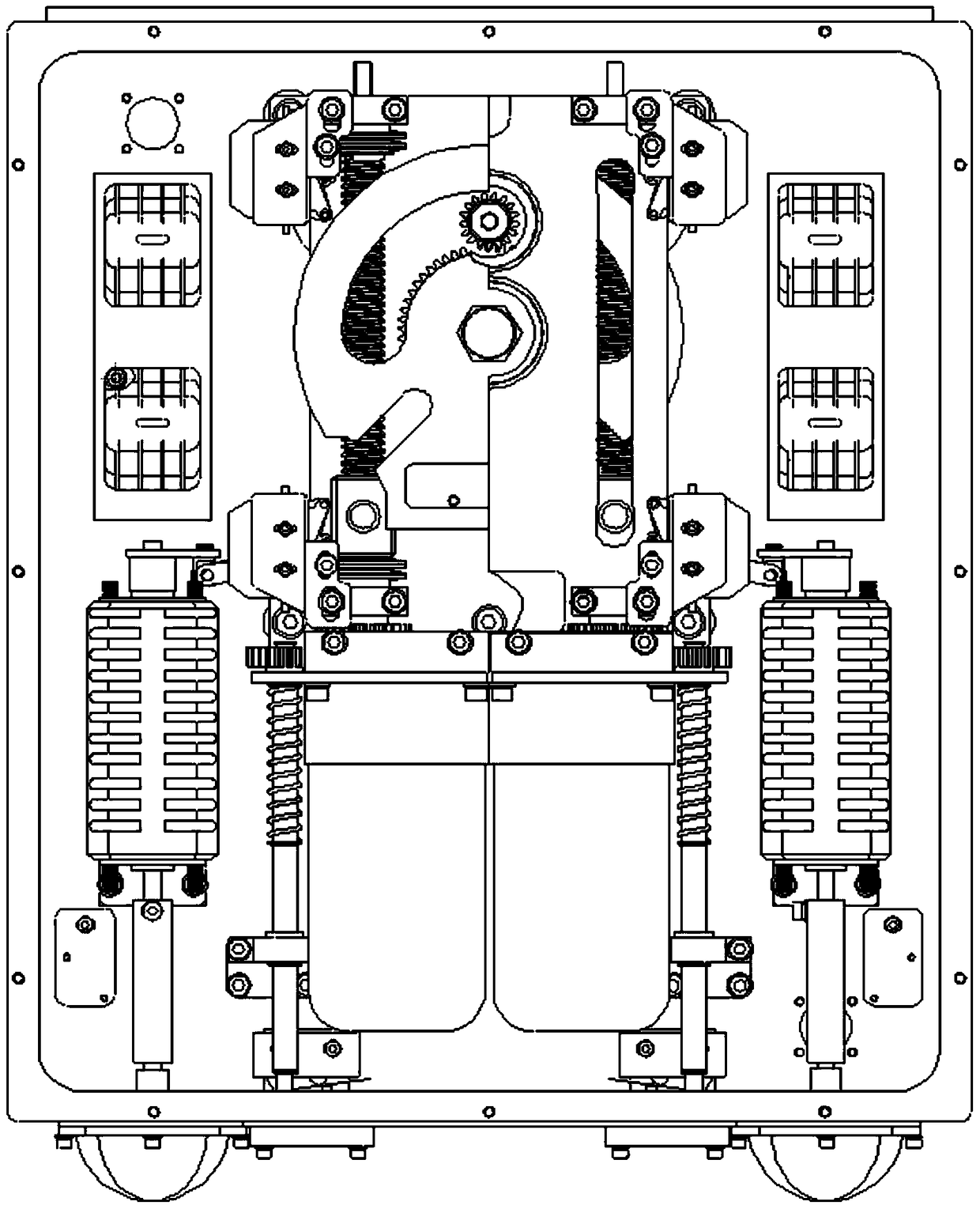

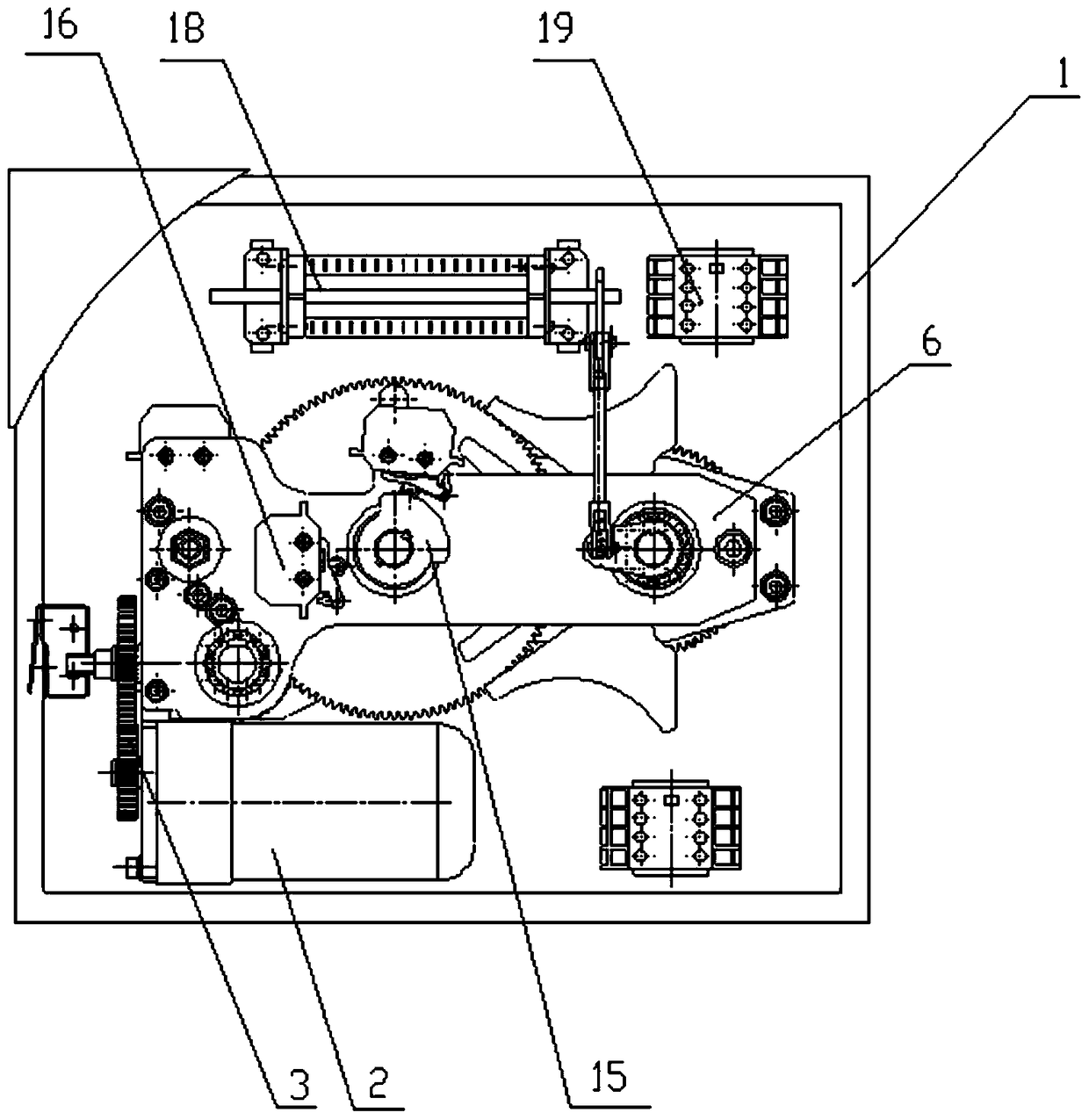

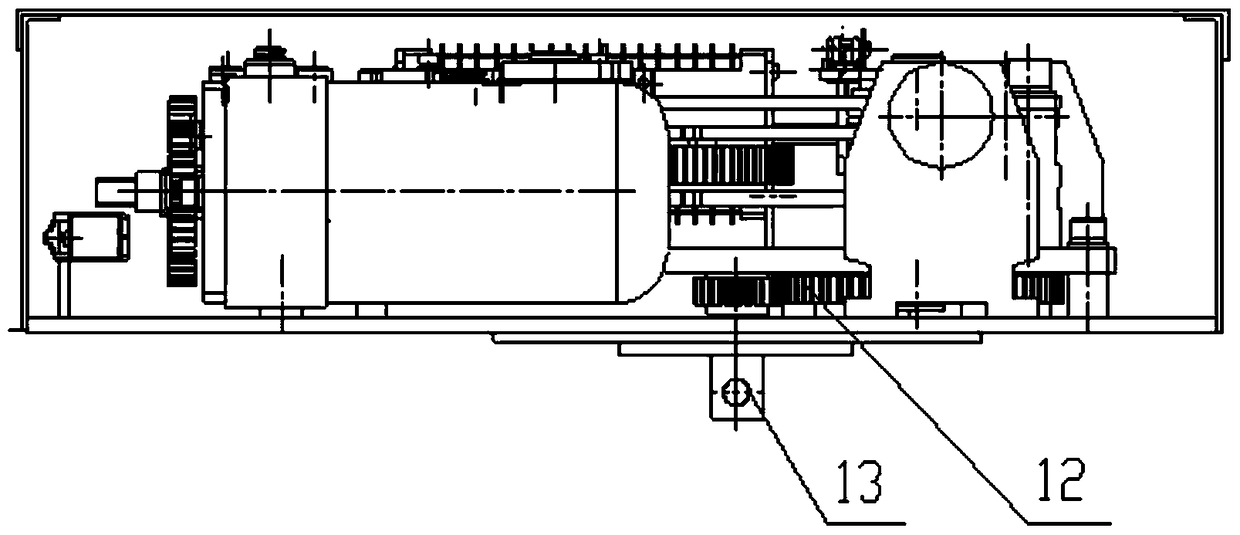

[0031] Such as Figure 2-6 As shown, the present invention includes a box body 1, a motor 2, a gear transmission mechanism, a main gear 8, a two-way grooved plate 10, an output gear set 12, a mechanism output shaft 13, an auxiliary switch 18, a contactor 19, an interlock mechanism and a buffer device 23 , each mechanism is arranged in the box body 1, wherein the upper mounting plate 6 and the lower mounting plate 5 are arranged in the box body 1, the main gear 8 is installed on the main gear shaft 7, and the two-way slotted plate 10 Installed on the grooved plate shaft 11, the main gear shaft 7 and the grooved plate shaft 11 are installed in parallel on the upper mounting plate 6 and the lower mounting plate 5.

[0032] Such as Figure 2-6 As shown, the gear transmission mechanism includes a primary transmission gear set 3, a manual output shaft 14 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com