A kind of preparation method of metal oxide-cellulose composite diaphragm

A technology of composite diaphragm and bacterial cellulose membrane, which is applied in the direction of nanotechnology, structural parts, electrical components, etc. for materials and surface science, and can solve the problems of low liquid absorption rate, low mechanical strength and ion conductivity of diaphragm electrolyte. and the small porosity of the diaphragm to achieve the effect of increased mechanical properties, low equipment requirements, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A Pre-compress 10mm aqueous bacterial cellulose wet film under 2MPa pressure for 60s at room temperature;

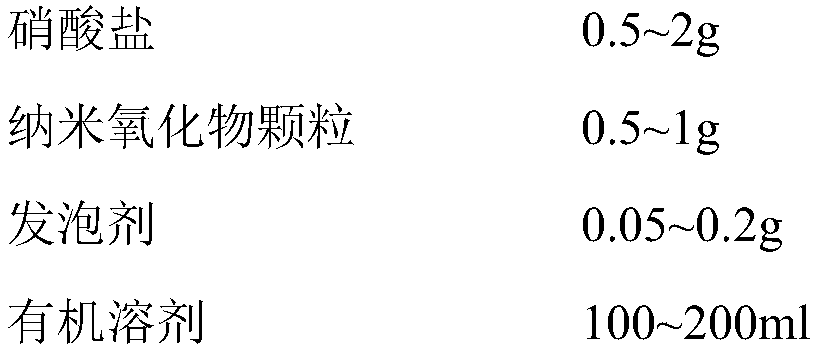

[0025] B according to the following ratio

[0026]

[0027]

[0028] Prepare a mixed solution, soak the bacterial cellulose membrane pre-pressed in step A in the mixed solution, perform physical adsorption, and take it out after 2 hours;

[0029] C. Place the bacterial cellulose film obtained by physical adsorption in step B to dry under 2MPa heat press. The heat press is divided into two steps: first heat press at 60°C for 20min to volatilize the organic solvent; then heat at 140°C Press for 10 minutes to decompose the aluminum nitrate adsorbed in the bacterial cellulose membrane to produce aluminum oxide and generate gas NH together with N-nitrosamine 3 , NO, NO 2 , to obtain a high-porosity metal alumina-cellulose composite separator.

[0030] The main components of the metal alumina-cellulose composite diaphragm are bacterial cellulose and alumina, an...

Embodiment 2

[0032] A Pre-press a 50mm aqueous bacterial cellulose wet film under a pressure of 0.1MPa for 10s at room temperature;

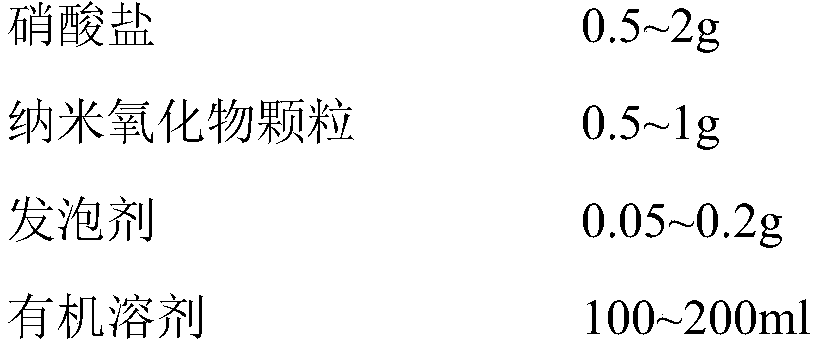

[0033] B according to the following ratio

[0034]

[0035] Prepare a mixed solution, soak the bacterial cellulose membrane pre-pressed in step A in the mixed solution, perform physical adsorption, and take it out after 2 hours;

[0036] C. Put the bacterial cellulose film obtained by physical adsorption in step B into a 0.1 MPa heat press for drying. The heat press is divided into two steps: first, heat press at 80° C. for 5 minutes to volatilize the organic solvent; and then dry it at 120° C. Hot pressing for 5 minutes, the aluminum nitrate adsorbed in the bacterial cellulose membrane is decomposed to produce metal aluminum oxide, and at the same time, the gas NH is produced together with N-nitrosamine 3 , NO, NO 2 , to obtain a high-porosity metal alumina-cellulose composite separator.

[0037] The main components of the metal alumina-cellulose comp...

Embodiment 3

[0039] A Pre-press 30mm of 30mm aqueous bacterial cellulose wet film under 0.4MPa pressure for 30s at room temperature;

[0040] B according to the following ratio

[0041]

[0042] Prepare a mixed solution, soak the bacterial cellulose membrane pre-pressed in step A in the mixed solution, perform physical adsorption, and take it out after 2 hours;

[0043] C. Dry the bacterial cellulose membrane obtained by physical adsorption in step B in a hot press at 0.4 MPa. The hot press is divided into two steps: first, hot press at 70°C for 10 minutes to volatilize the organic solvent; then dry at 130°C. Hot pressing for 10 minutes, the iron nitrate adsorbed in the bacterial cellulose membrane is decomposed to produce metal iron oxide, and at the same time, the gas NH is produced together with N-nitrosamide 3 , NO, NO 2 , to obtain a metal oxide-cellulose composite separator with high porosity.

[0044] The main components of the metal alumina-cellulose composite diaphragm are b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com