Partitioning type stator crimping apparatus

A press-fitting device and block-based technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve problems such as scratches on the inner wall of the water jacket, and achieve the effects of good assembly quality, good roundness, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

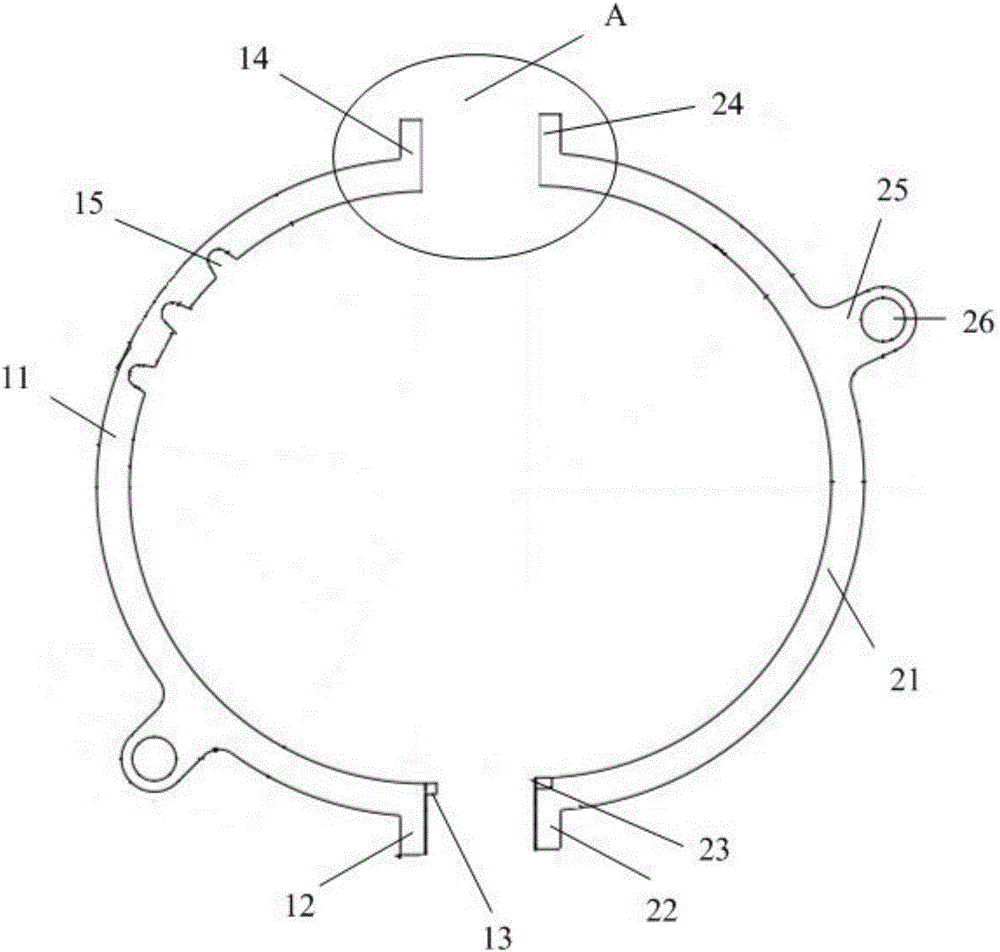

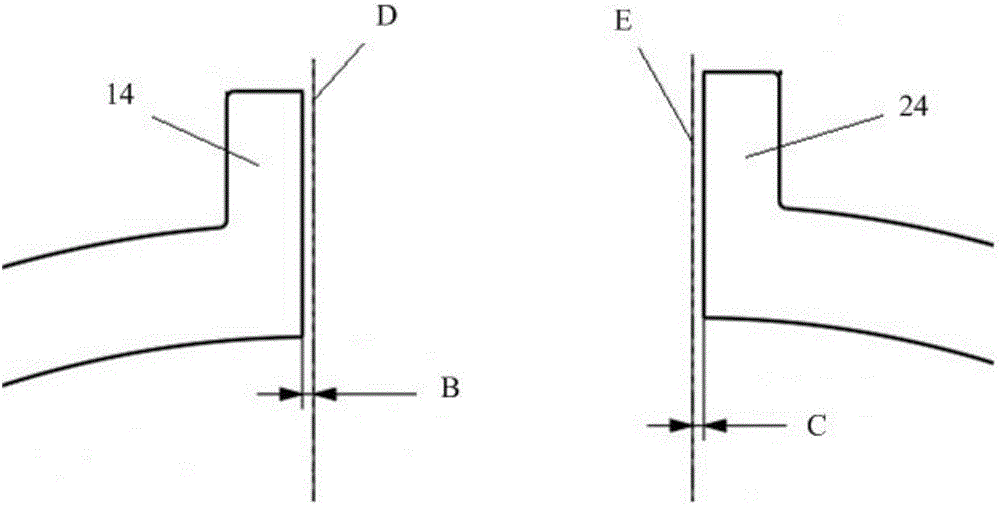

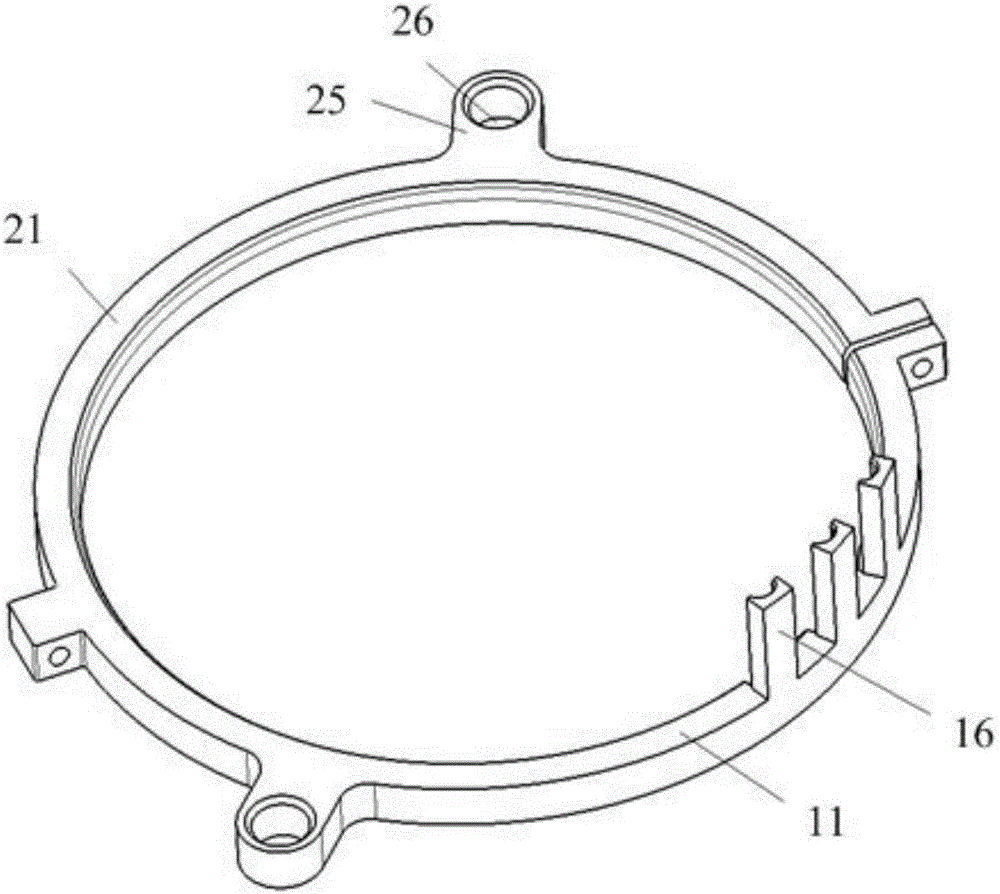

[0047] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a segmented stator press-fitting device, which includes a mounting ring. The mounting ring includes a first semicircular ring 11 that fits with the outer surface of one side of the stator 31 and the other side of the stator 31. The second semicircular ring 21 that fits the outer surface of one side, the end face of the first end of the first semicircular ring 11 is provided with the positioning protrusion 13, and the end face of the connecting end of the second semicircular ring 21 is provided with There is a positioning groove 23 matched with the positioning protrusion 13; the first end is provided with a first mounting riser 12 on the side away from the second end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com