Light emitter and light detector modules including vertical alignment features

A technology of vertical alignment and optical transmitter, which is applied in photometry, instrumentation, optics and other directions using electric radiation detectors. It can solve the problems of focal length change and performance degradation of optical transmitter modules, etc., and achieve improved beam focusing and operation. Good effect of promoting beam focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

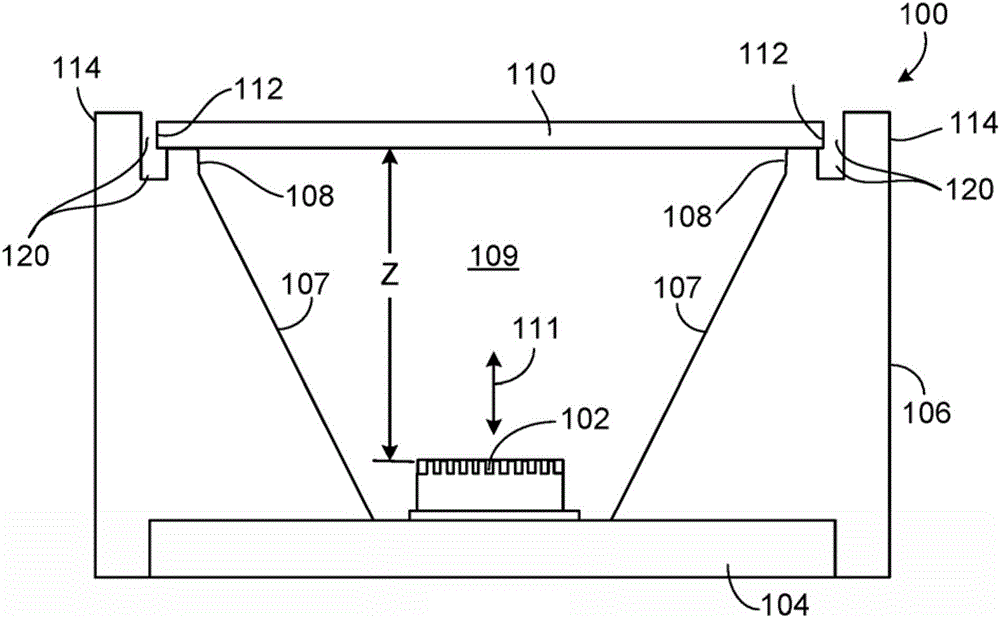

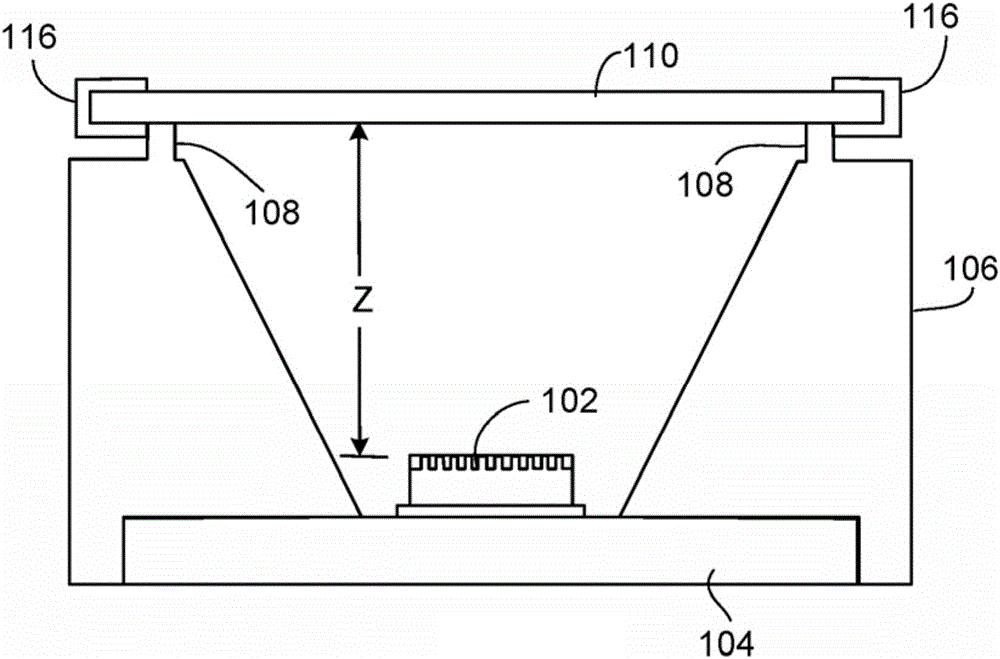

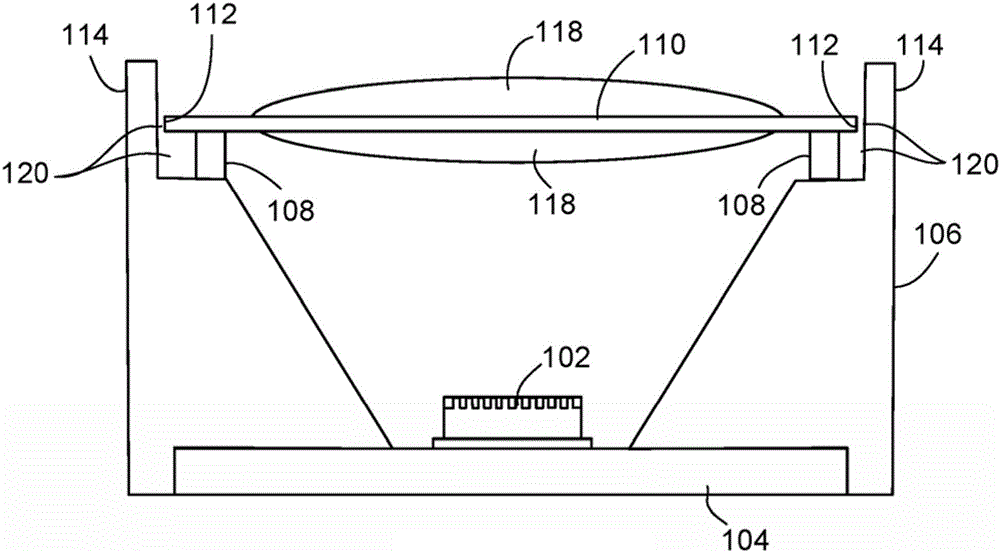

[0030] Such as Figure 1A As shown, the packaged light emitter module 100 can provide ultra-precise and stable packaging for the light emitter 102 mounted on a substrate 104, such as a lead frame. The light emitter 102 may be of the type that generates coherent, directional, spectrally defined light emission (eg, a vertical cavity surface emitting laser (VCSEL) or a laser diode). In some implementations, the light emitter 102 is operable to emit infrared (IR) light or light within the visible range of the spectrum. Since the operating temperature of the light emitter 102 can be relatively high, the lead frame or other substrate 104 can be constructed of a material such as a copper alloy that exhibits low thermal expansion. Such materials have relatively high thermal conductivity and thus may also help to provide good thermal management for the module. For example, a substrate mainly composed of copper (which has a thermal conductivity of about 260W / (mK)) can help conduct hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com