Full automatic jujube pit remover

A fully automatic jujube pitting technology, applied in fruit pitting devices, food science, applications, etc., can solve problems such as poor adaptability, affecting the accuracy of punching pits, complex movement, etc., and achieve high production efficiency, high work efficiency, and movement smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited.

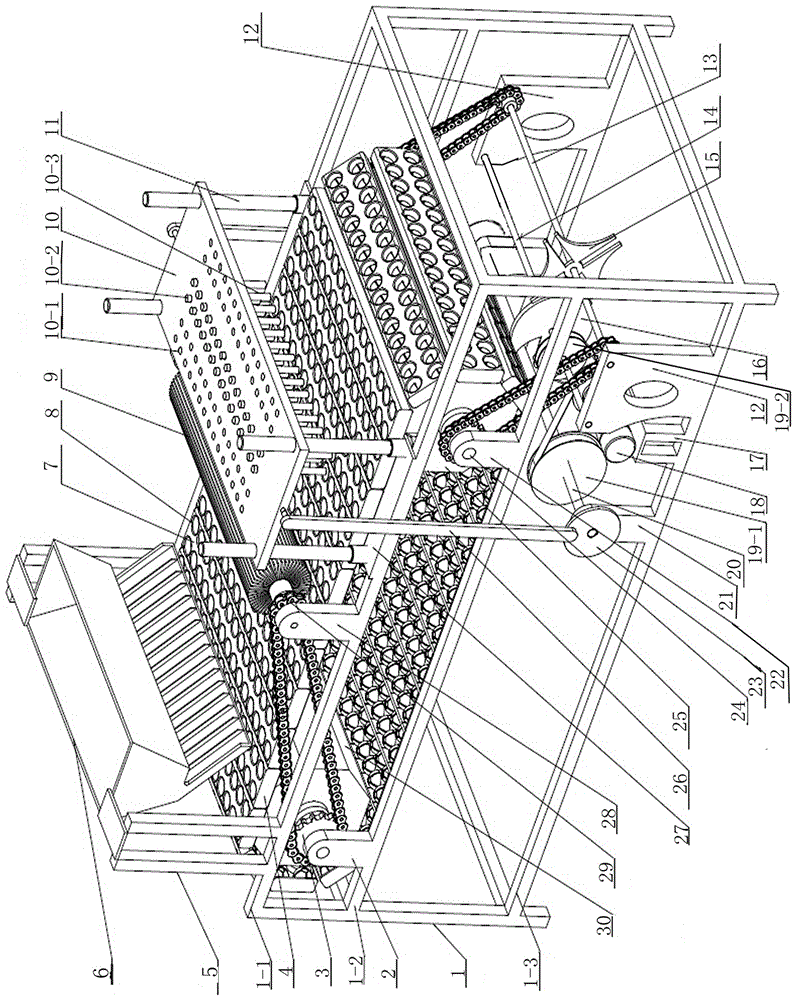

[0028] refer to figure 1 , a kind of fully automatic jujube pitting machine, comprises frame 1, is arranged on the feeding device on frame 1, transmission device and pitting device;

[0029] The frame 1 is a Japanese-shaped rectangular structure, including an upper connecting rod 1-1, a middle connecting rod 1-2 and a lower connecting rod 1-3;

[0030] The feeding device includes a feed hopper 6 located at the front of the frame 1, the outlet of the feed hopper 6 is connected to the denucleating device on the frame 1 through a conveying crawler 4, and one end of the conveying crawler 4 is connected to the The outer wall of the main positioning roller 25 is connected, the other end of the transmission crawler 4 is connected with the outer wall of the auxiliary positioning roller 30 located at the bottom of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com