Overhead rail type firefighting inspection robot system

A technology of inspection robots and hanging rails, which is applied in the directions of manipulators, fire rescue, and manufacturing tools, etc., can solve the problems of inability to extinguish fires, complex positioning and control of wheeled and tracked fire-fighting robots, and the inability to prevent fires, etc., to achieve prevention Improve the efficiency of fire, inspection and fire extinguishing, and the effect of simple control and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further explained below in conjunction with the accompanying drawings.

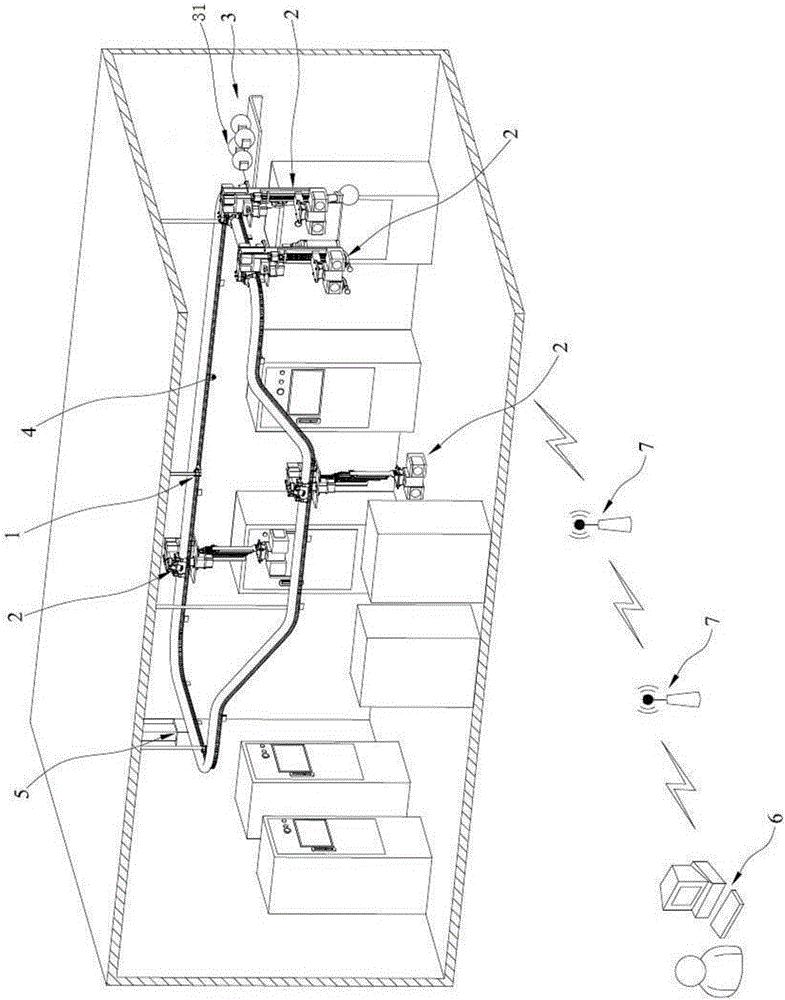

[0056] like Figures 1 to 3 As shown, a hanging rail type fire inspection robot system of the present invention includes: hanging rail part 1, hanging rail type fire inspection robot 2, fire extinguishing equipment 3, position identification block 4, charging point 5, remote control center 6 , Wireless signal transmission equipment 7.

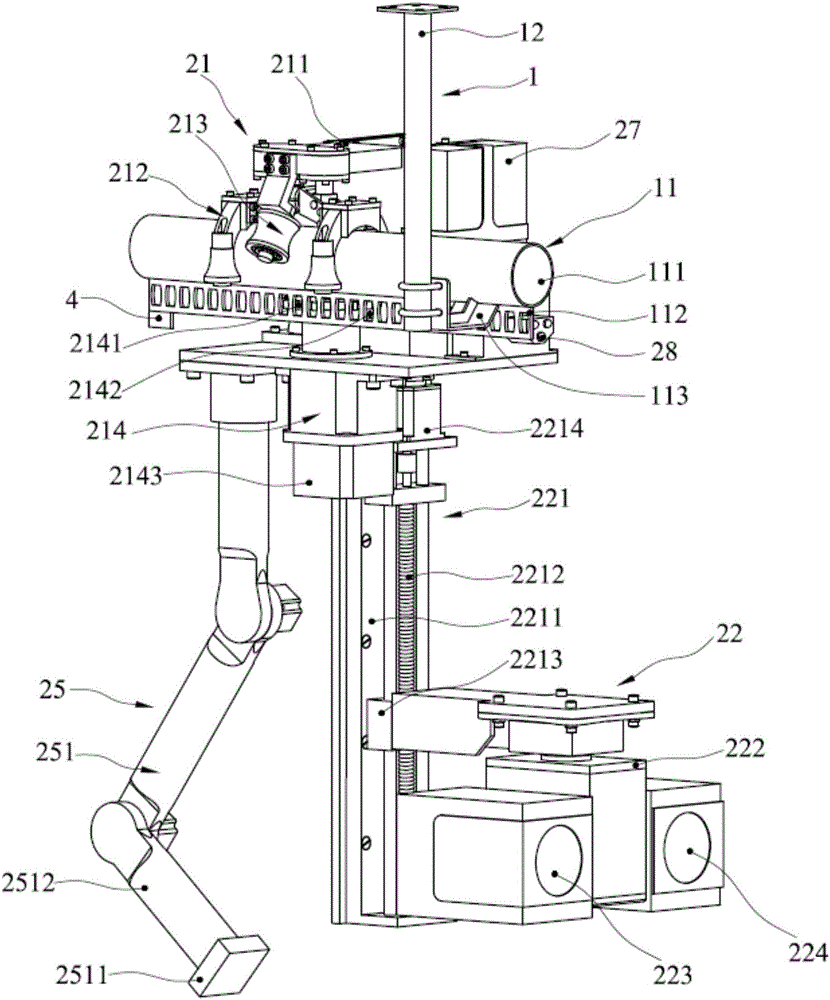

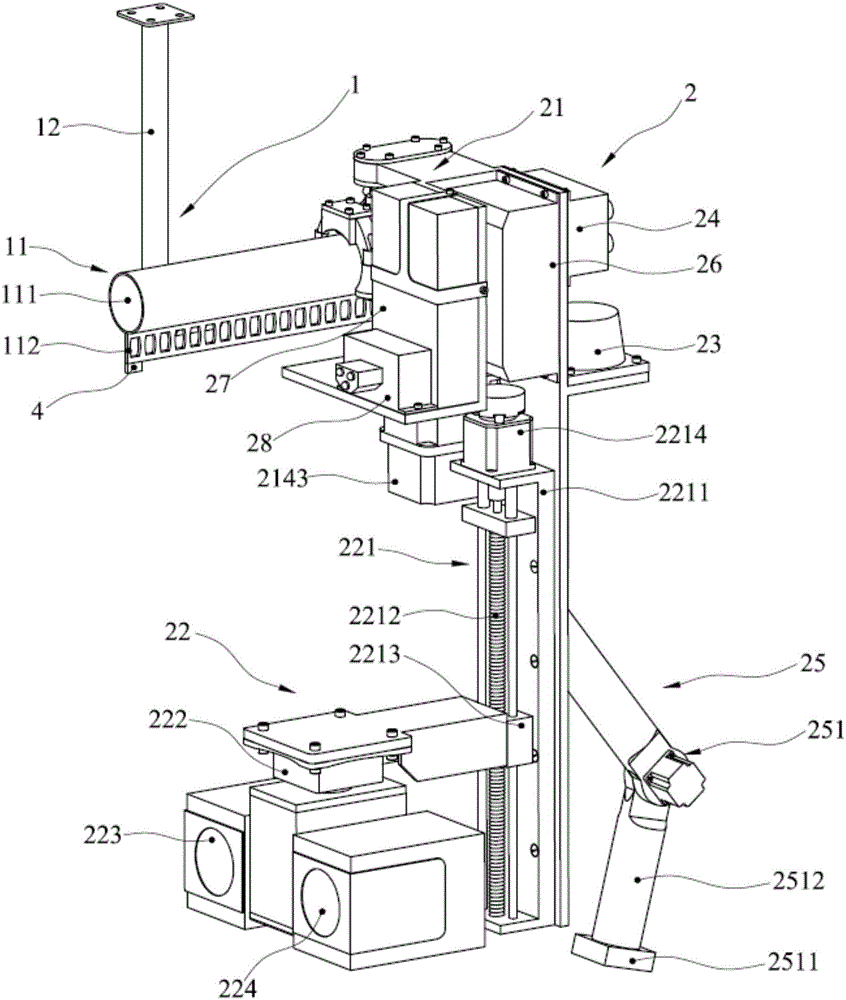

[0057] The suspension rail part 1 includes a rail 11 and a hanger 12 for hoisting the rail 11 in the air. The rail 11 includes: a rail body 111 whose cross-sectional profile is circular; rack rails 112 , the rack 112 is fixed on the bottom of the rail body 111 .

[0058] There are multiple rail-mounted fire-fighting inspection robots 2, all of which move on the track 11. The plurality of rail-mounted fire-fighting inspection robots 2 are connected by communication. 2 includes: walking part 21, lifting vision device 22, position detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com