Fast detection device for automobile headlights

A technology of automobile headlights and detection devices, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of product loading quality, increase the difficulty of headlights, and easy wear and tear of movable parts, etc., to achieve detection Convenience, improved detection accuracy and work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

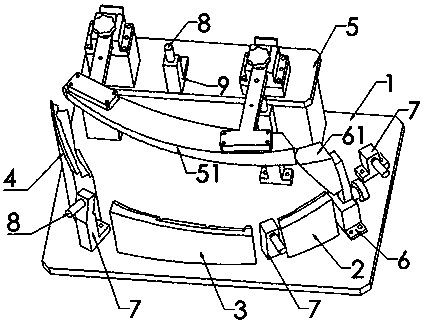

[0010] Depend on figure 1 It is a three-dimensional schematic diagram of the present invention, a rapid detection device for automobile headlights, including an operating console 1, and the operating console 1 is also provided with a simulation block I2, a simulation block II3, a simulation block III4, and a turning mechanism I5 , overturning mechanism II6, four detection pin blocks I7, the overturning mechanism I5 is provided with an analog block IV51, and the overturning mechanism II6 is provided with an analog block V61; through the analog block I2, the analog block II3, the analog block III4, and the analog block Ⅳ51 and the analog block Ⅴ61 form a product shape detection port; the flipping mechanism Ⅰ5 is also provided with a detection pin block Ⅱ9, and the detection pin block Ⅰ7 and the detection pin block Ⅱ9 are equipped with detection pin holes, and the detection pin 8 It is flexibly connected in the detection pin hole; the turning mechanism I5 and turning mechanism II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com