Engine accessory transmission assembly transporter

A technology for accessory transmission and transportation devices, applied in transportation and packaging, motor vehicles, multi-axis trolleys, etc., can solve the problems of lower assembly efficiency and assembly quality, chaotic distribution and installation, and prone to errors, etc., to meet the needs of efficient and reliable transportation , meet the needs of transportation, improve the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

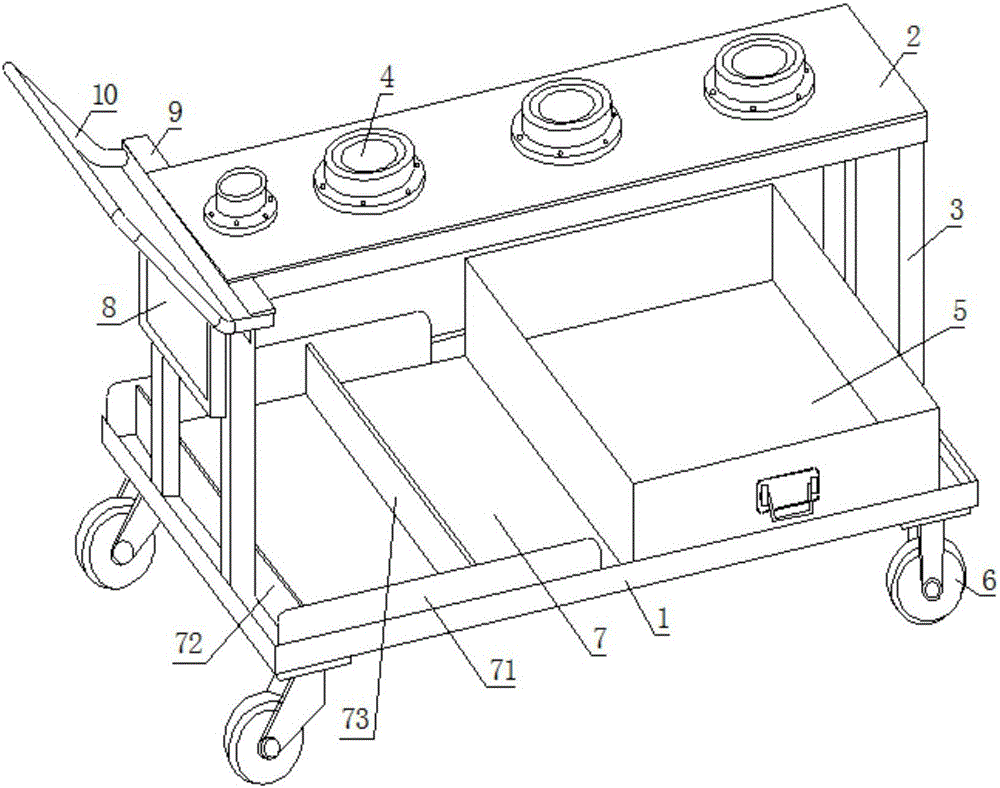

[0017] Such as figure 1 As shown, a transportation device for an engine accessory transmission assembly according to the present invention includes a chassis 1 and a top plate 2, and the chassis 1 and the top plate 2 are connected by a support column 3, and several transmissions are arranged on the top plate 2. The device assembly mounting base 4, the chassis 1 are respectively provided with a component storage box 5 and a transmission housing component storage area 7. In this technical solution, the transmission assembly mounting seat 4 is designed according to the shape and size of the transported engine accessory transmission assembly, and can be a main fuel pump mounting seat, an afterburner fuel pump mounting seat, a booster pump mounting seat, and a generator mounting seat; Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com