Light garbage collection device of belt conveyor

A belt conveyor and garbage collection technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as insufficient automation, blockage of coal bunker discharge ports, and increased output costs, and achieve garbage collection Simple and convenient, increase the service life, reduce the effect of cost output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

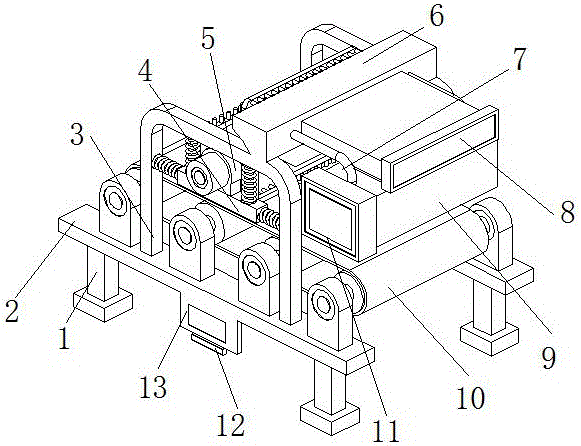

[0023] A light garbage collection device for a belt conveyor, comprising a bracket, the bracket includes four supporting feet 1 arranged in parallel and side by side, a crossbeam 2 is arranged on the top of any two supporting feet, and a crossbeam 2 is respectively arranged on the two crossbeams 2 A U-shaped bracket 3 is installed between the two beams 2. A garbage conveying device composed of a belt conveyor 10 is installed. The belt conveyor 10 is electrically connected to a PLC controller 13 located on any beam, and is realized by the PLC controller 13. The start and stop states of the belt conveyor 10. The bottom end of the PLC controller 13 is provided with a wireless transceiver 12 to realize remote control.

[0024] A garbage picking device and a garbage pumping device are also arranged on the support.

[0025] The rubbish pick-up device comprises rotary motor 5 and turns over and selects fork 14, and rotary motor 5 is arranged on any one fixed on the fixture in U-shap...

Embodiment 2

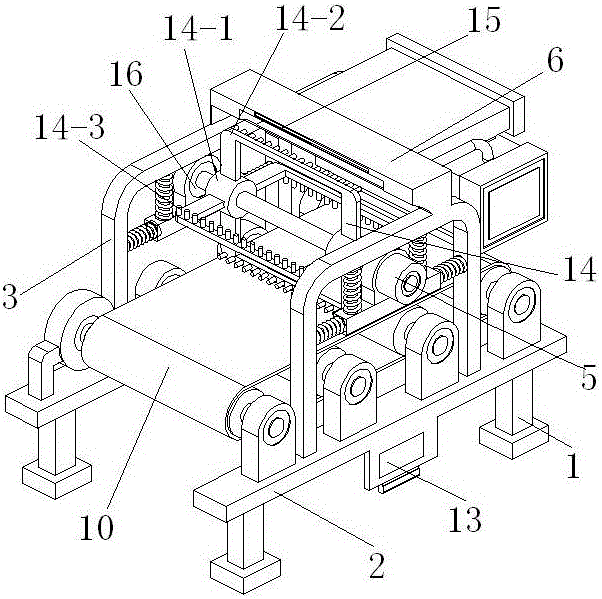

[0031] A light garbage collection device for a belt conveyor, comprising a bracket, the bracket includes four supporting feet 1 arranged in parallel and side by side, a crossbeam 2 is arranged on the top of any two supporting feet, and a crossbeam 2 is respectively arranged on the two crossbeams 2 A U-shaped bracket 3 is installed between the two beams 2. A garbage conveying device composed of a belt conveyor 10 is installed. The belt conveyor 10 is electrically connected to a PLC controller 13 located on any beam, and is realized by the PLC controller 13. The start and stop states of the belt conveyor 10. The bottom end of the PLC controller 13 is provided with a wireless transceiver 12 to realize remote control.

[0032] A garbage picking device and a garbage pumping device are also arranged on the support.

[0033] Garbage pick-up device comprises rotary motor 5 and turns over and selects fork 14, and rotary motor 5 is arranged on any mounting bracket 4-1 that is fixed in ...

Embodiment 3

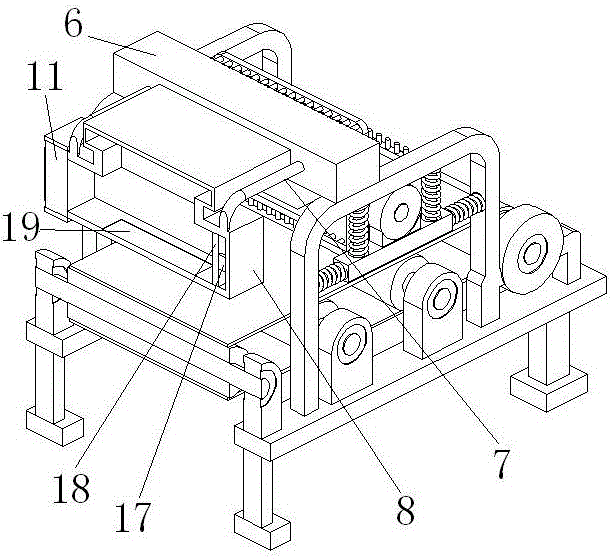

[0040] A light garbage collection device for a belt conveyor, comprising a bracket, the bracket includes four supporting feet 1 arranged in parallel and side by side, a crossbeam 2 is arranged on the top of any two supporting feet, and a crossbeam 2 is respectively arranged on the two crossbeams 2 A U-shaped bracket 3 is installed between the two beams 2. A garbage conveying device composed of a belt conveyor 10 is installed. The belt conveyor 10 is electrically connected to a PLC controller 13 located on any beam, and is realized by the PLC controller 13. The on-off state of the belt conveyor 10. The bottom end of the PLC controller 13 is provided with a wireless transceiver 12 to realize remote control.

[0041] A garbage picking device and a garbage pumping device are also arranged on the support.

[0042] Garbage pick-up device comprises rotary motor 5 and turns over and selects fork 14, and rotary motor 5 is arranged on any mounting bracket 4-1 that is fixed in U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com