A rail transport device for rock pile slope building materials and its installation and use method

A technology for rail transportation and building materials, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., which can solve the problems of trolley sliding, high cost, and easy spillage of building materials, etc., to achieve low cost, improve high cost, The effect of easy disassembly and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

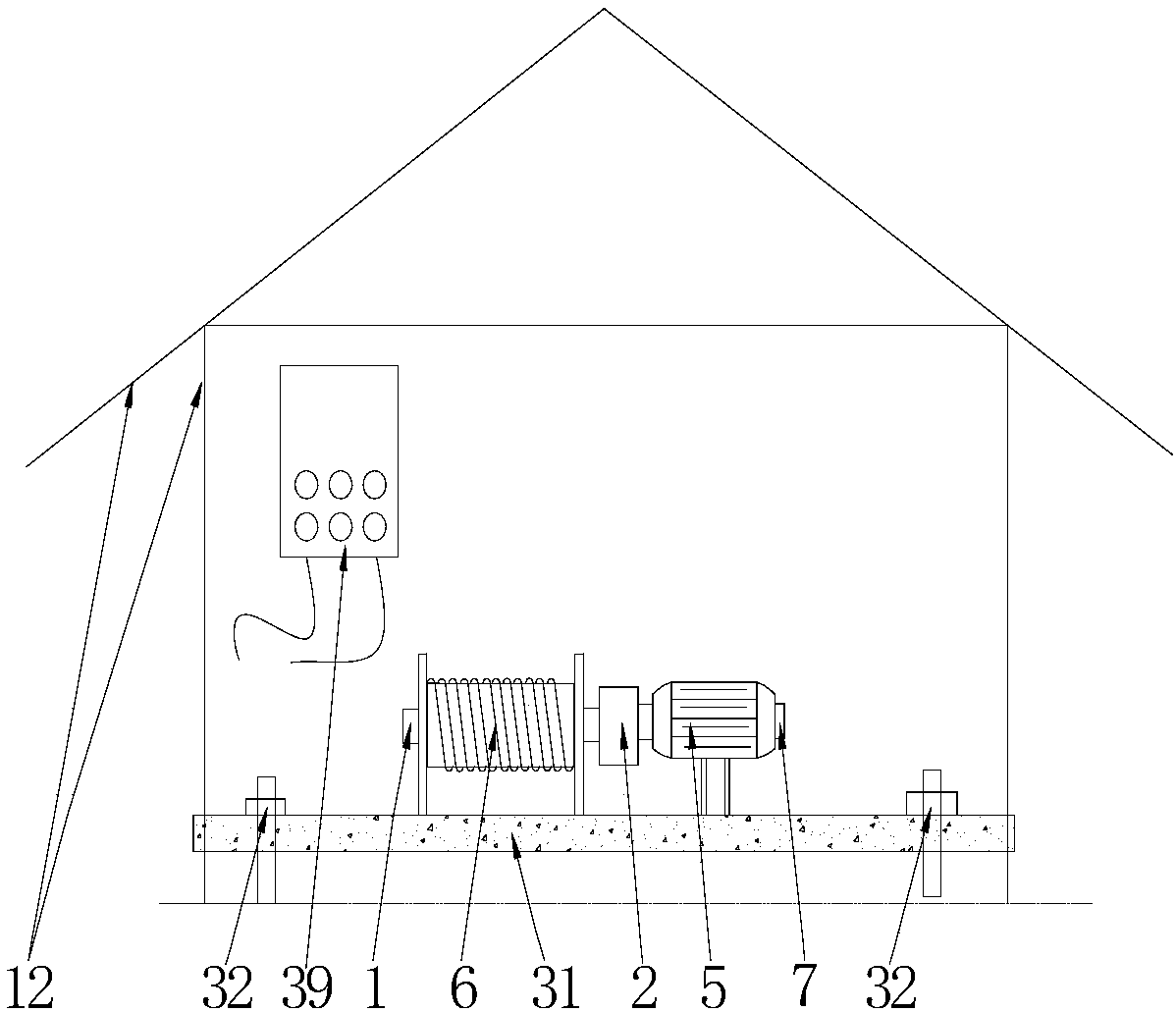

[0053] In this example, by surveying and mapping the rock pile slope at the entrance of the Daqian Shiling Tunnel in Neitianhuan Railway, Liaoning Province, the topographic features of the rock pile are obtained, that is, the rock pile slope at the entrance of the tunnel is located on the left bank of the Daya River, and the slope faces NE30 °, the slope fluctuates slightly along the uphill direction, generally changing between 26-38°, and the altitude of the slope foot is about 410m.

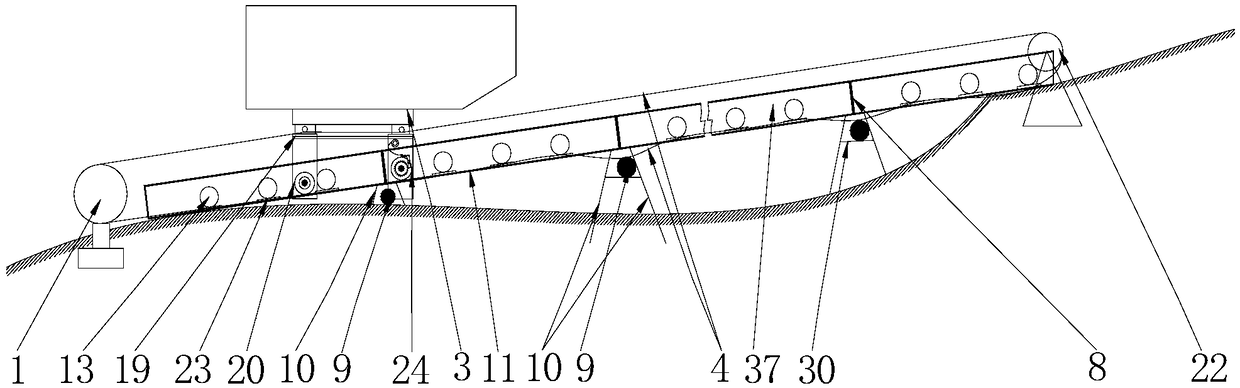

[0054] In this example, in order to further investigate the distribution law of rock piles at the entrance rock slope of Daqian Shiling Tunnel on Tianhuan Railway, several exploratory wells with a depth of 30 to 40 m were excavated on the rock piles. The wall of the exploratory well shall be treated with a retaining wall, which is composed of steel bars and concrete. Because the slope surface of the rock pile side slope is uneven, if the construction materials such as concrete are time-consumin...

Embodiment 2

[0077] In this embodiment, taking the rock pile slope at the entrance of the Daqian Shiling Tunnel of Neitianhuan Railway in Liaoning Province as an example, a method for using a construction material rail transport device adapted to the rock pile slope is disclosed, including the following installation steps:

[0078] S1: Carry out on-site survey of the rock pile slope and the destination of material transportation, and determine the position of the hoist operating device from the perspective of economy and safety.

[0079] S2: Do a good job of laying out the line, determine the installation baseline and elevation of the track, and the direction of the track should meet the relevant national standards.

[0080] S3: According to the topography, geology and track weight, the reasonable length of a single track is determined to be 2m.

[0081] S4: Level the site where the hoist operating device is located, pour concrete square cap, the cap is 432m above sea level, connect the ca...

Embodiment 3

[0092] In this embodiment, a method for using a construction material rail transport device adapted to rock pile slopes is disclosed, including the following steps:

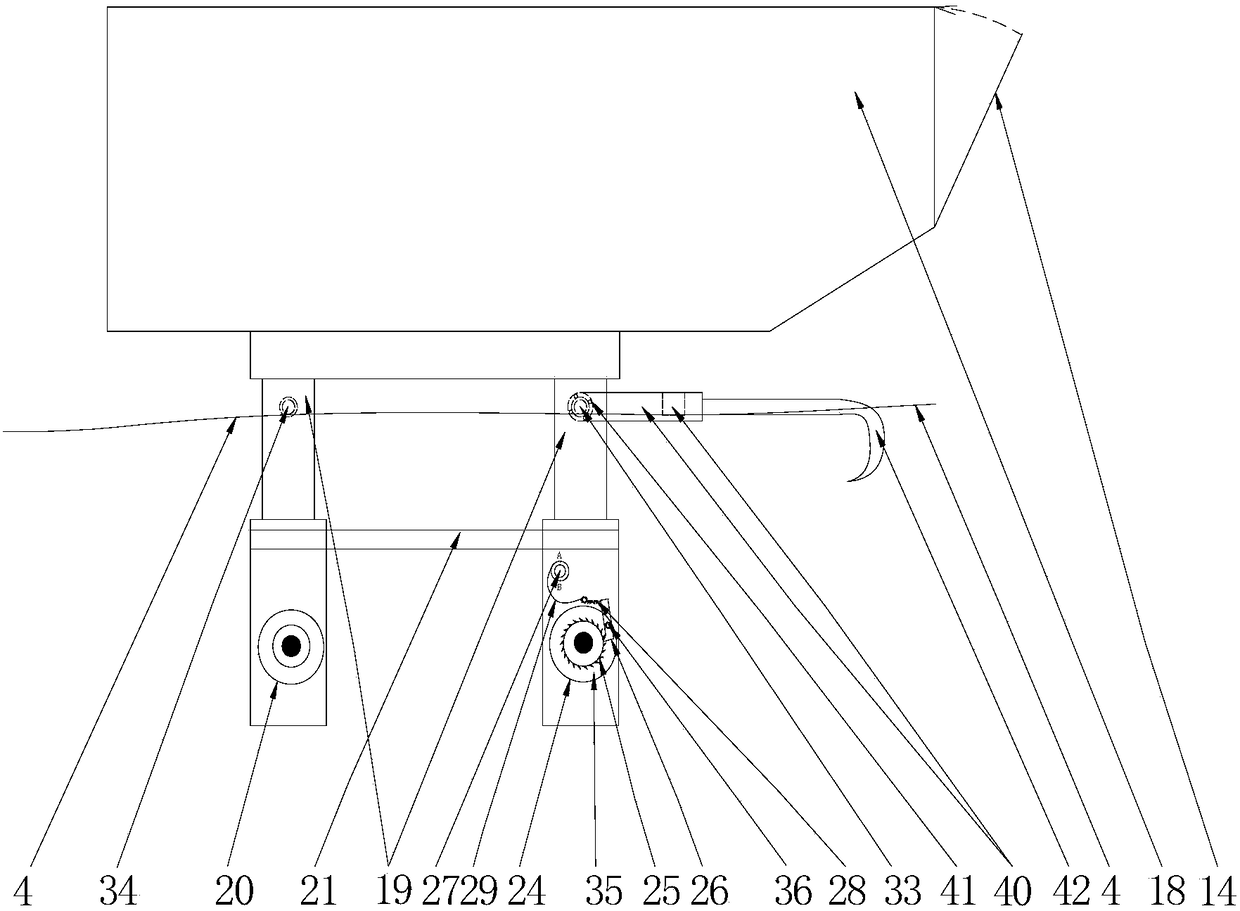

[0093] S14: Safety inspection: Turn off the main switch in the distribution box, and conduct a comprehensive safety inspection, mainly including checking whether the connection between the traction steel rope and the feeding trolley is reliable, and whether the traction rope is seriously damaged.

[0094] S15: Adjust the hydraulic telescopic legs of the feeding trolley: According to the protrusion of rock blocks on the side slope of the rock pile and the slope of the track within the track range, adjust the hydraulic telescopic legs of the feeding trolley to keep the hopper of the feeding trolley always level. In this way, it can prevent and reduce the impact of the hopper of the feeding trolley on the protruding rock blocks and the outward throwing of building materials during the material transportation process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com