Square column concrete member wood-plastic formwork reinforcement clamping apparatus and use method thereof

A technology of wood-plastic formwork and concrete, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, building construction, etc. It can solve the problems of high formwork pressure, poor reinforcement rigidity, mold expansion and formwork joint cracking Solve problems such as slurry leakage, achieve the effect of convenient assembly and disassembly, guarantee the locking effect, and improve the locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

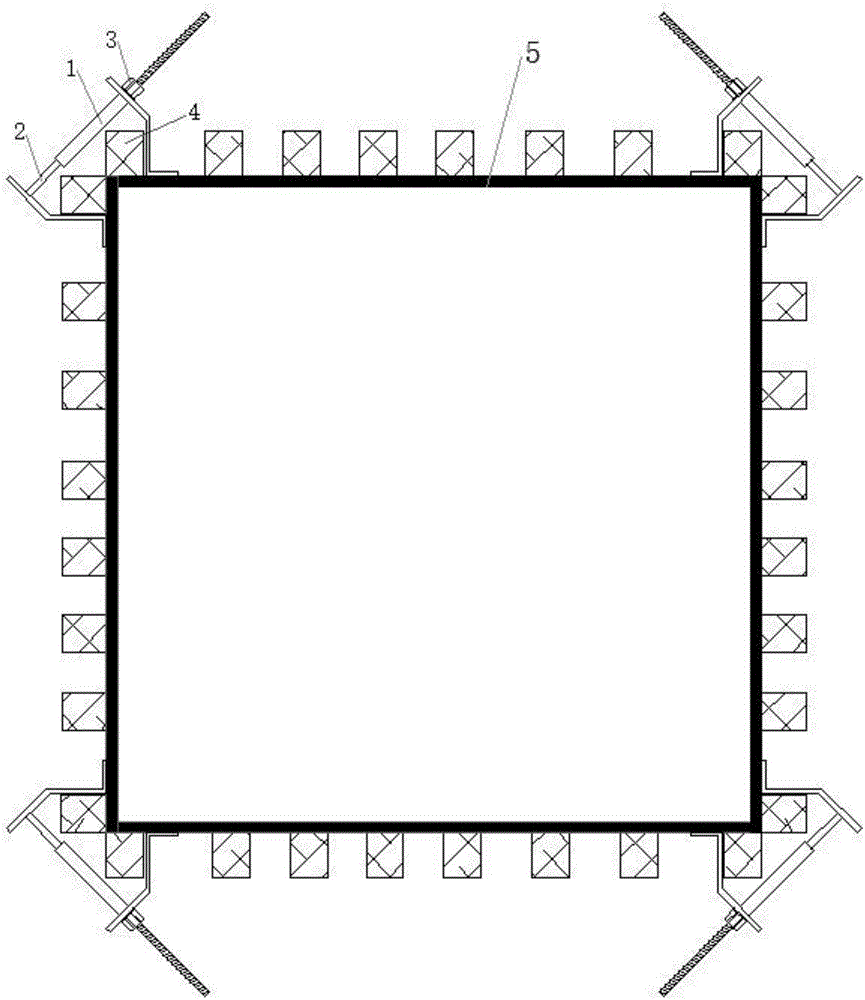

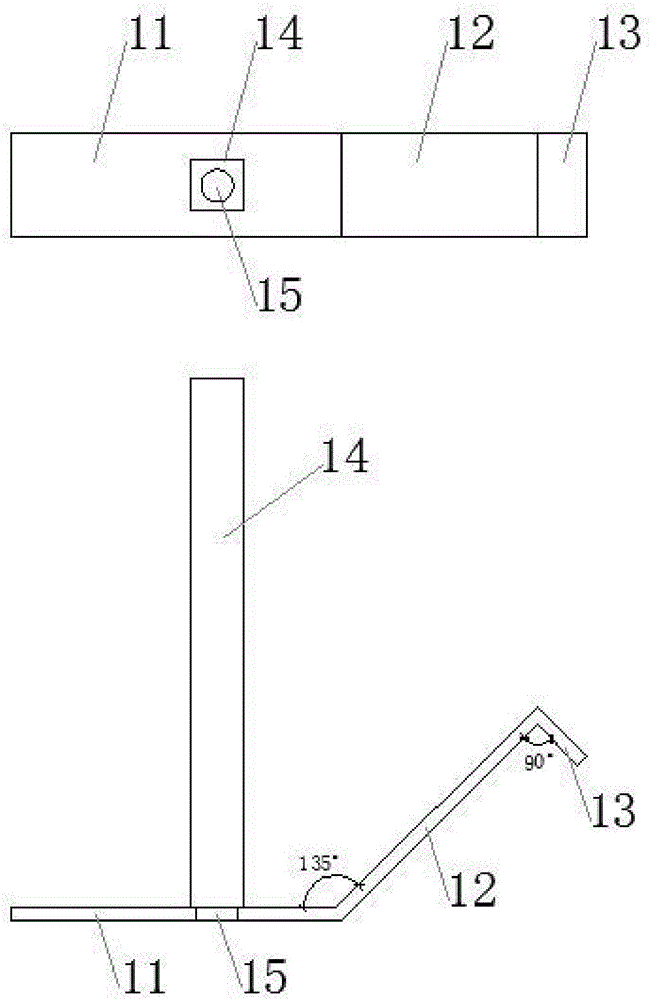

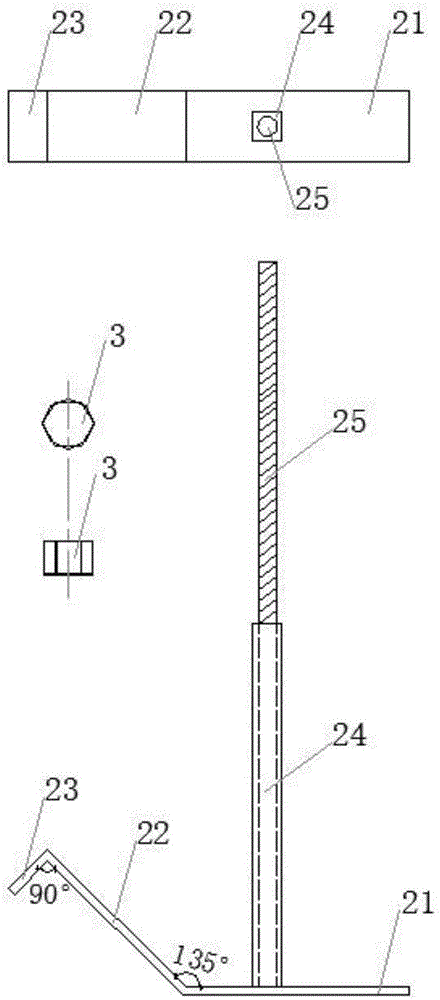

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a wood-plastic formwork reinforcement clamp for square column concrete members includes a male end 2, a female end 1 and a locking structure arranged between the male end 2 and the female end 1, and the male end 2 includes a male end clamping part And the locking part of the male end, the locking part of the male end includes the contact arm 23 of the male end and the connecting arm 22 of the male end; Rod 24, the end of the connecting rod is provided with a threaded part 25; the female end 1 includes a female end clamping part and a female end locking part, and the female end clamping part includes a female end contact arm 13 and a female end connecting arm 12; the female end lock The tightening part includes a female locking arm 11 and a hollow locking cylinder 14 fixed inside the female locking arm 11. The female locking arm 11 is also provided with a through hole 15, and the through hole 15 is locate...

Embodiment 2

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a method for using a wood-plastic formwork reinforcement fixture for a square column concrete member, including a concrete member 5 and a formwork back flute 4 evenly arranged outside the concrete member 5, the female end contact arm 13 and the male end contact arm 23 Respectively close to the two sides of the right angle of the concrete member 5, the female end connecting arm 12 and the male end connecting arm 22 are respectively close to the side of the formwork back corrugated 4, the connecting rod 24 of the locking structure passes through the through hole 15 and the hollow lock The column 14, the nut 3 is locked on the threaded part 25, and the locking position of the nut can be adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com