Non-excavation drilling rod with thread protecting structure

A thread protection, non-excavation technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of poor sealing, thread breakage, poor practicability, etc., achieve improved torque resistance, save manufacturing and maintenance costs, and save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

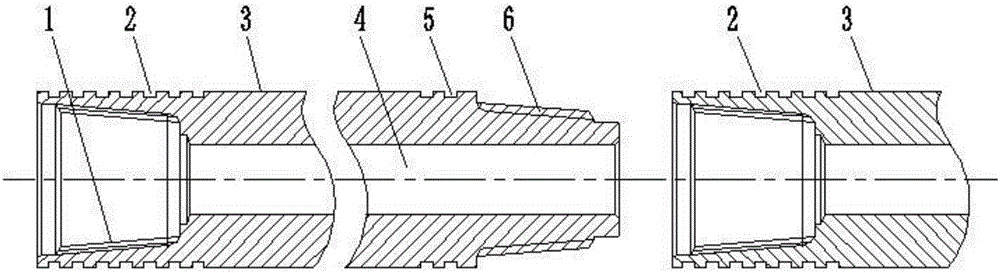

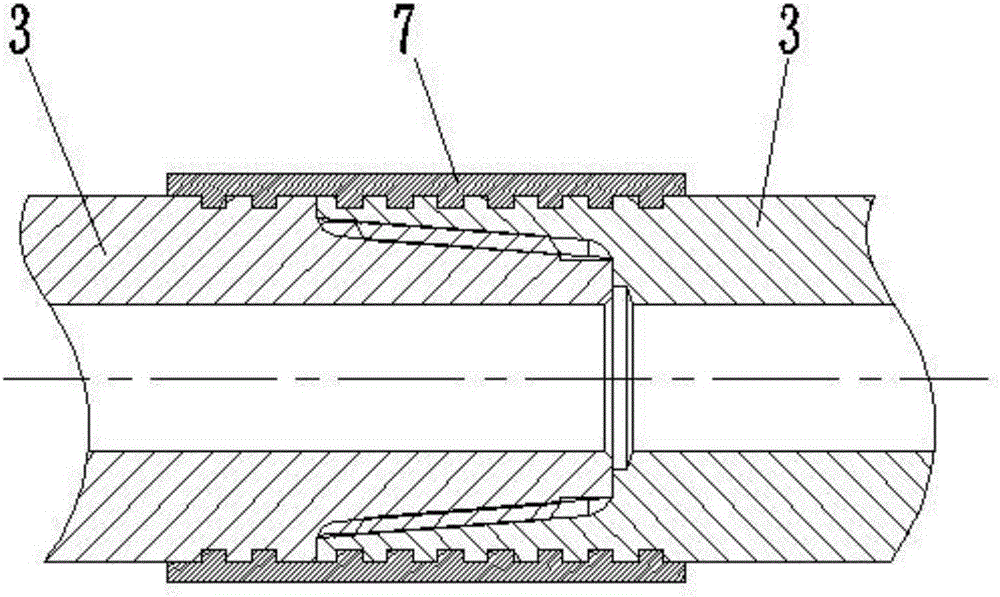

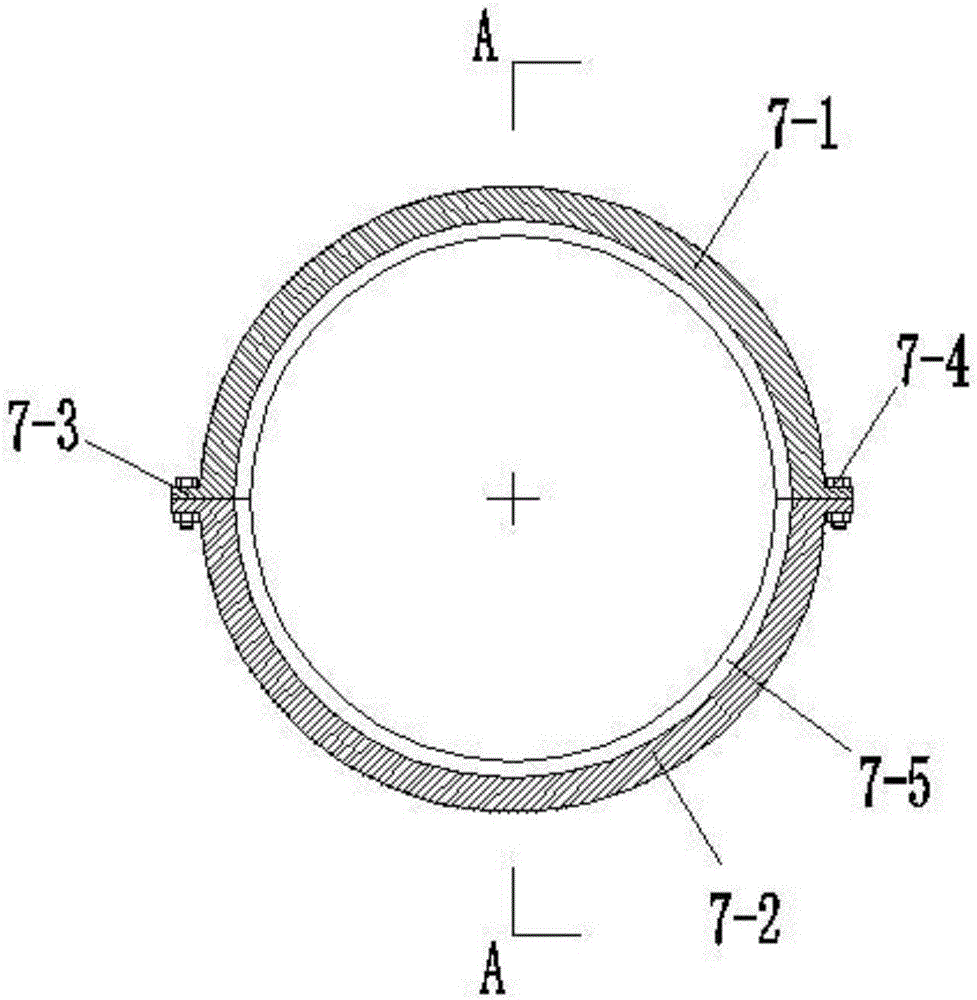

[0017] Such as Figure 1-4 As shown, the non-excavation drill pipe with thread protection structure includes a shaft 3, a drill pipe inner cavity 4 arranged inside the shaft 3, a male joint 6 arranged at the head of the shaft 3 and a tail end of the shaft 3 The outer circle of the male joint 6 is provided with a male joint outer circular groove 5, and the outer circle corresponding to the female joint 1 is provided with a female joint outer circular groove 2, and the outer circle of the male joint 5 and the outer circle of the female joint The circular groove 2 is provided with a thread protection device 7, and the thread protection device 7 is composed of an upper retainer 7-1, a lower retainer 7-2 and a connecting bolt 7-4, and the upper retainer 7-1 and the lower retainer 7- The inner surfaces of 2 are provided with guards 7-5, and the guards 7-5 are respectively engage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com