Fan mounting mechanism

A technology for installing mechanisms and fans, which is applied in the direction of pump devices, electromechanical devices, mechanical equipment, etc., and can solve problems such as inability to recycle lubricating oil and fans without installation means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

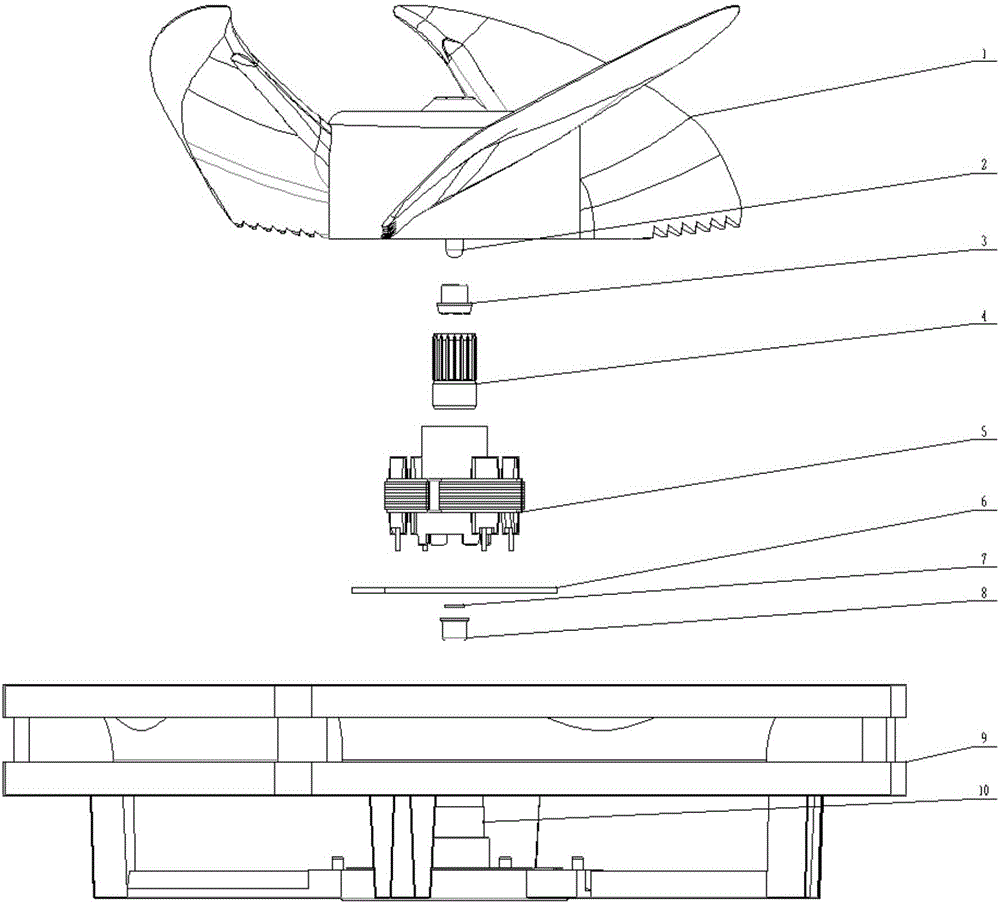

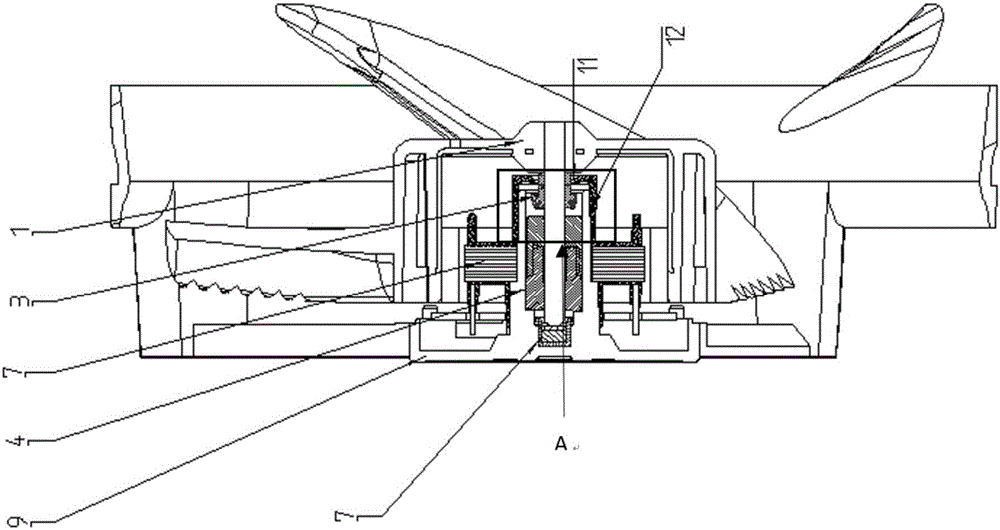

[0016] Such as figure 1 As shown, it includes a mount 9, a magnetic sleeve assembly 7, a graphite baffle 8, a stator core 5, an oil bearing 4, a limit sleeve 3, and a motor shaft 2; the mount 9 is provided with a receiving hole 10; One end of the motor shaft 2 is fixed to the blade main body 1, and passes through the limit sleeve 3 and the oil bearing 4 in turn, and can rotate relative to the limit sleeve 3 and the oil bearing 4; the limit sleeve 3 and the oil bearing 4 are installed on Inside the receiving hole 10 , the stator core 5 is set outside the receiving hole 10 and installed on the circuit board 6 ; the circuit board 6 is installed on the mounting seat 9 .

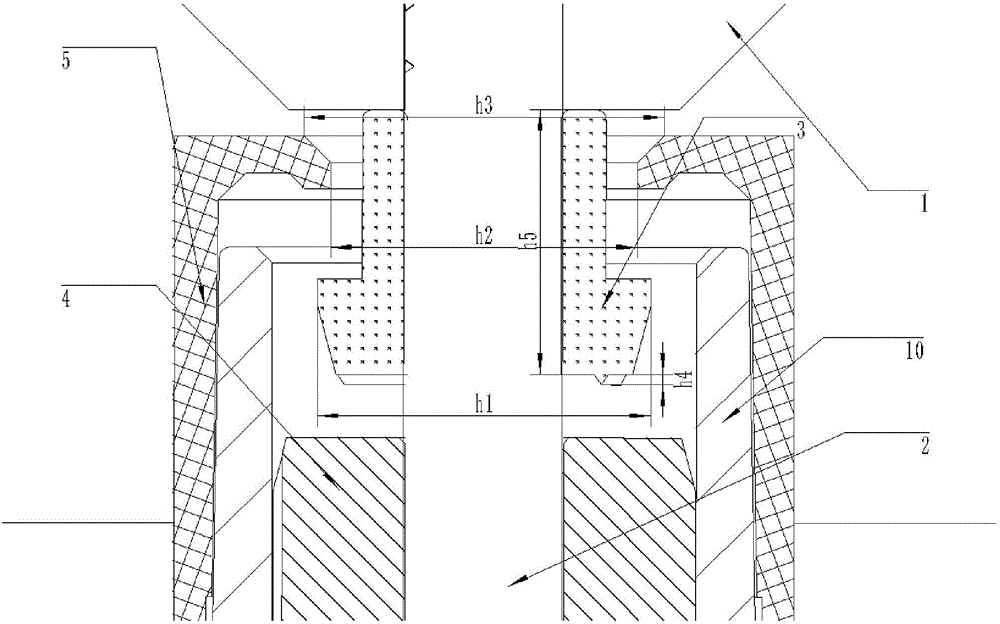

[0017] Such as figure 2 with 3 As shown, the stator core 5 is provided with an opening above the receiving hole 10, and the cross-sectional shape of the opening is trapezoidal.

[0018] Such as Figure 4 As shown, the limit sleeve 3 is an inverted T-shaped structure, and the lower end of the limit sleeve 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com