An ultrasonic measurement method for the internal temperature field of a uniform material component

An internal temperature, ultrasonic measurement technology, applied in thermometers, heat measurement, measurement devices, etc., can solve problems affecting structural safety and stability, high temperature of structural parts, structural failure, etc. Measure the effect of simple operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

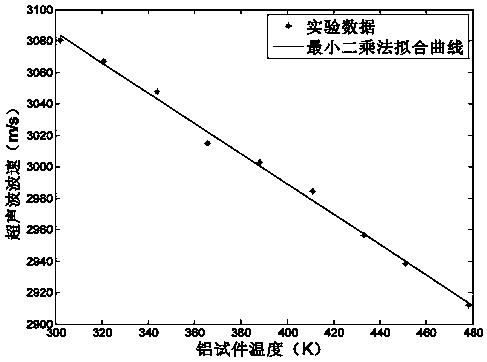

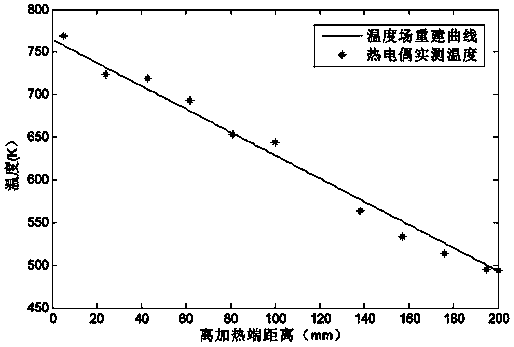

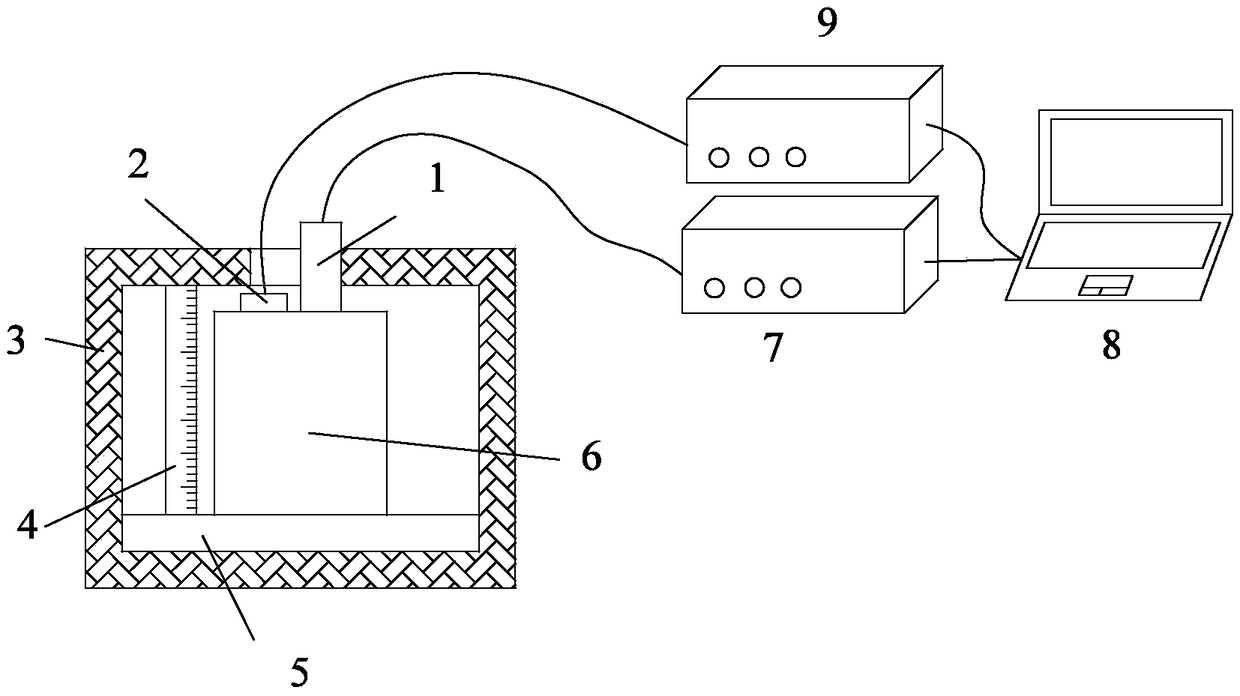

[0049] use as figure 1 As shown in the device, proceed to step one. First, a uniform aluminum material in the shape of a cylinder is selected as the calibration sample 6 (specific dimensions such as figure 2 As shown), use the ruler 4 to measure the thickness d of the calibration sample 6, which is 200mm; then, install the high-temperature ultrasonic probe 1 and the patch-type thermocouple 2 on the top surface of the calibration sample 6, and connect the high-temperature ultrasonic probe 1 and the ultrasonic measurement Meter 7 is connected to obtain T in different temperature states i Ultrasonic transit time t in sub-calibration sample 6 i , the chip type thermocouple 2 is connected with the thermocouple measuring instrument 9, to obtain the temperature of the top surface of the calibration sample 6, the ultrasonic measuring instrument 7 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com