A Method for Observing Martensitic Variation of Mnnige-Based Alloys

A technology for martensite and base alloys, which is applied in the field of observing the microstructure of MnNiGe base alloys, and achieves the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

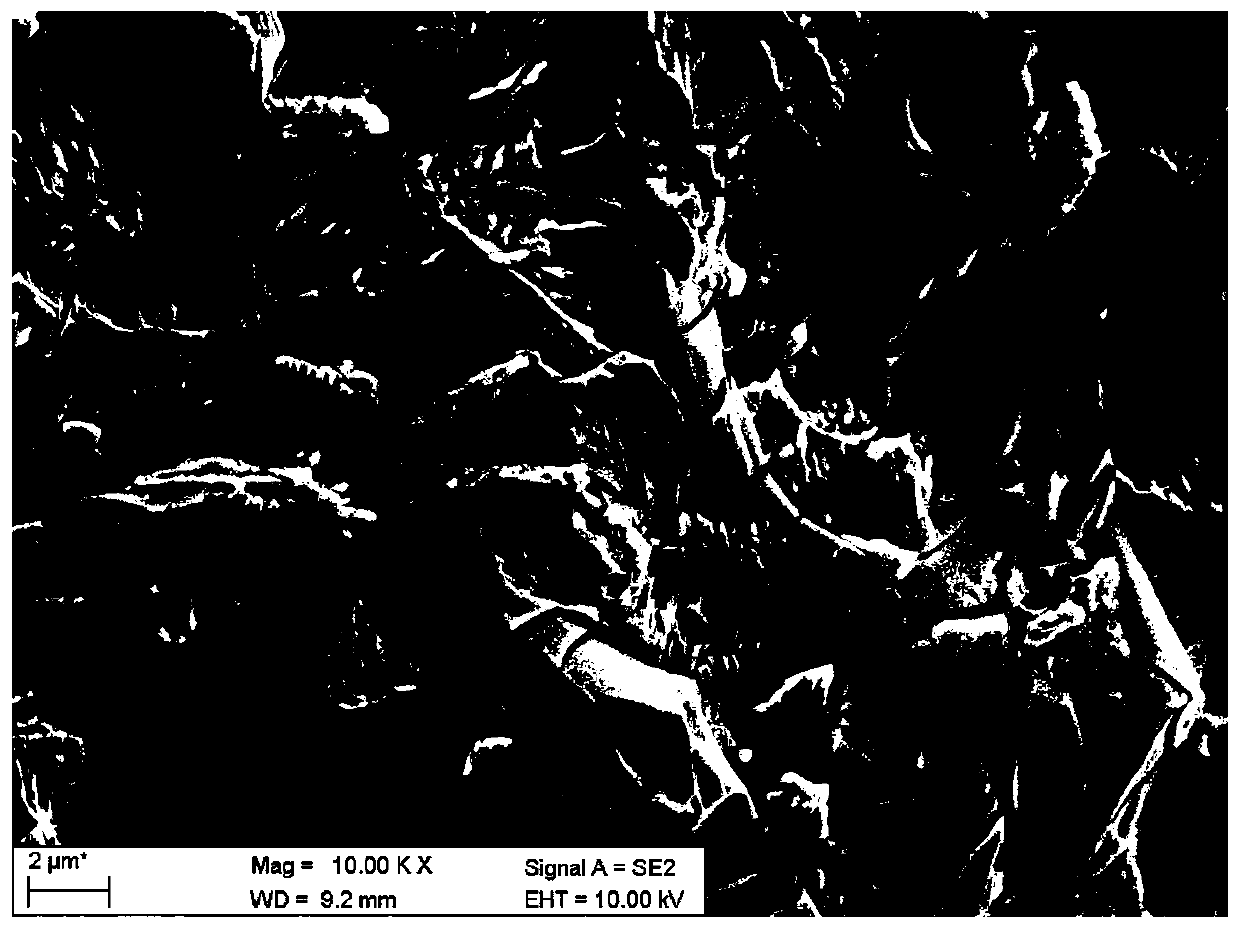

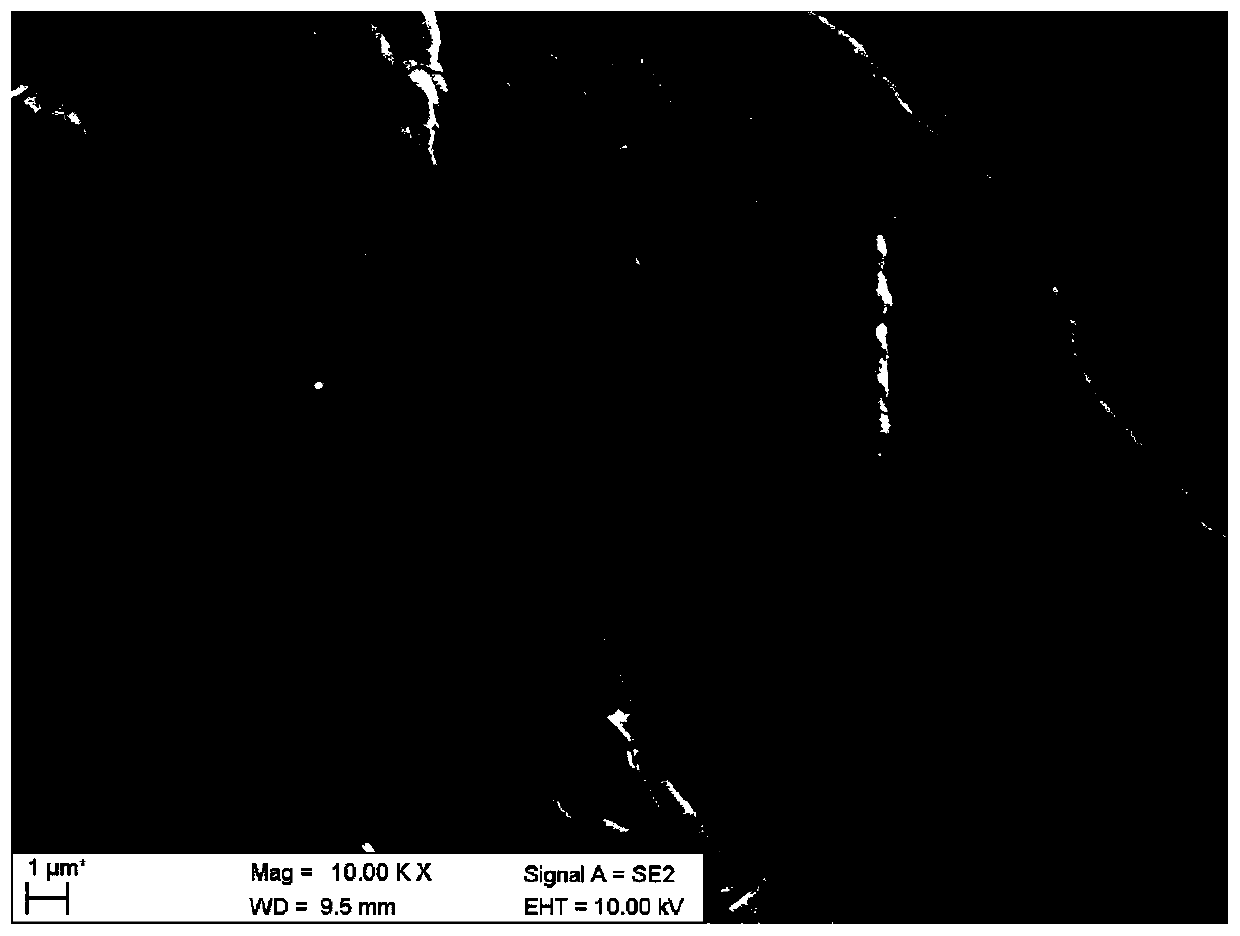

Image

Examples

Embodiment 1

[0021] (1) sample preparation: calculate the quality of Mn, Ni, Ge metal simple substance that composition distribution ratio is required for MnNiGe by stoichiometric ratio, put the prepared raw material into the copper crucible of water-cooled electric arc furnace and repeat smelting 3 times, Obtain a relatively uniform Mn-Ni-Ge-based alloy ingot, polish off the surface oxide layer of the ingot, put it into a quartz tube with an inner diameter of 10-11mm, and then pressurize the ingot melted by high-frequency induction heating equipment through the A small hole with a diameter of about 0.05-0.2mm at the bottom of the quartz tube is sprayed onto a water-cooled copper mold to obtain a rod with a sample diameter of 1-6mm;

[0022] (2) Heat treatment: Put a part of the rod sample into a drawn quartz tube with an inner diameter of 10-11mm that has been closed at one end, and after vacuuming (below 4 Pa), quickly burn off the slender part of the quartz tube with an acetylene flame. ...

Embodiment 2

[0027] (1) Sample preparation: Calculate the composition ratio according to the stoichiometric ratio as MnNi 0.89 Fe 0.11 The quality of the metal elemental substance required by Ge, the prepared raw materials are repeatedly smelted 3 times to obtain alloy ingots, the oxide layer on the surface of the ingots is polished off, put into a quartz tube with an inner diameter of 10-11mm, and then pressurized by nitrogen to make the high-frequency The ingot melted by the induction heating equipment is sprayed onto the water-cooled copper mold through the small hole at the bottom of the quartz tube with a diameter of about 0.05-0.2mm, so as to obtain a rod with a sample diameter of 1-6mm;

[0028](2) Heat treatment: put a part of the rod sample into a drawn quartz tube with an inner diameter of 10-11mm that has been closed at one end, and after vacuuming, use an acetylene flame to quickly burn off the slender part of the quartz tube, and the rod sample Sealed in a vacuumed quartz tub...

Embodiment 3

[0032] (1) Sample preparation: Calculate the composition ratio as MnNi 0.78 Fe 0.22 To obtain the quality of the metal elemental substance required by Ge, repeat the smelting of the prepared raw materials 3 times to obtain an alloy ingot, polish off the oxide layer on the surface of the ingot, put it into a quartz tube with an inner diameter of 10-11mm, and pressurize it with nitrogen to make the alloy ingot The ingot melted by the frequency induction heating equipment is sprayed onto the water-cooled copper mold through the small hole at the bottom of the quartz tube with a diameter of about 0.05-0.2mm, so as to obtain a rod with a sample diameter of 1-6mm;

[0033] (2) Heat treatment: put a part of the rod sample into a drawn quartz tube with an inner diameter of 11mm that has been closed at one end, and after vacuuming, quickly burn off the slender part of the quartz tube with an acetylene flame, and seal the rod sample into the quartz tube. Put the sealed sample into a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com