Turn-to-turn insulation defect detection method

A technology of inter-turn insulation and detection method, which is applied in the direction of using optical methods to test and test the dielectric strength, etc., which can solve the problem of reactor ignition and combustion, the inability to locate inter-turn insulation defects, and limit the inter-turn insulation defects of dry-type air-core reactors Detect problems such as technological development and progress, to achieve the effect of improving operational reliability and reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

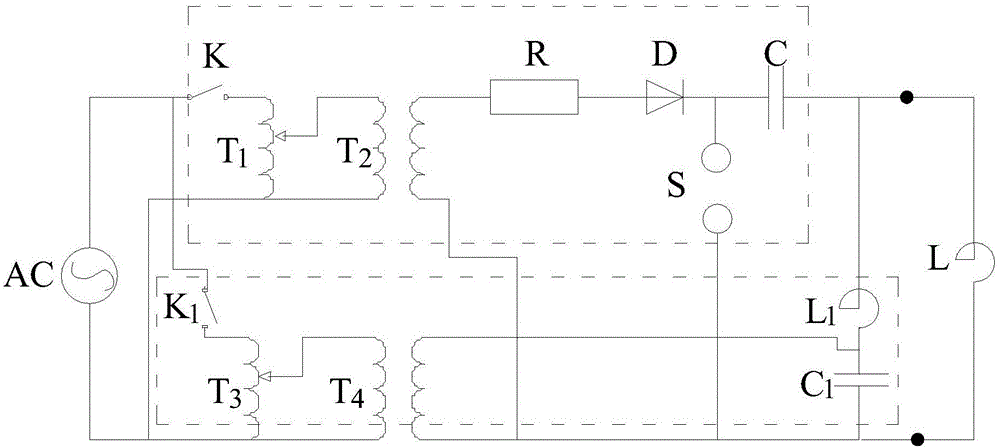

[0023] see figure 1 , a detection method for inter-turn insulation defects, the steps are as follows:

[0024] Step 1: Establish a superposition circuit in which the power frequency circuit and the high-frequency pulse oscillation circuit are superimposed on each other. The superposition circuit includes a first voltage regulating transformer, a protection resistor R, a rectifier silicon stack D, a charging capacitor C, and a blocking circuit that are connected in series to form a closed loop. Inductance L 1 and compensation capacitor C 1 , the protection resistor R is connected to the first output terminal of the first voltage regulating transformer, and the compensation capacitor C 1 It is connected to the second output end of the first voltage regulating transformer, one end of the discharge ball gap S is connected between the rectifier silicon stack D and the charging capacitor C, and the other end of the discharge ball gap S is connected to the first regulator connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com