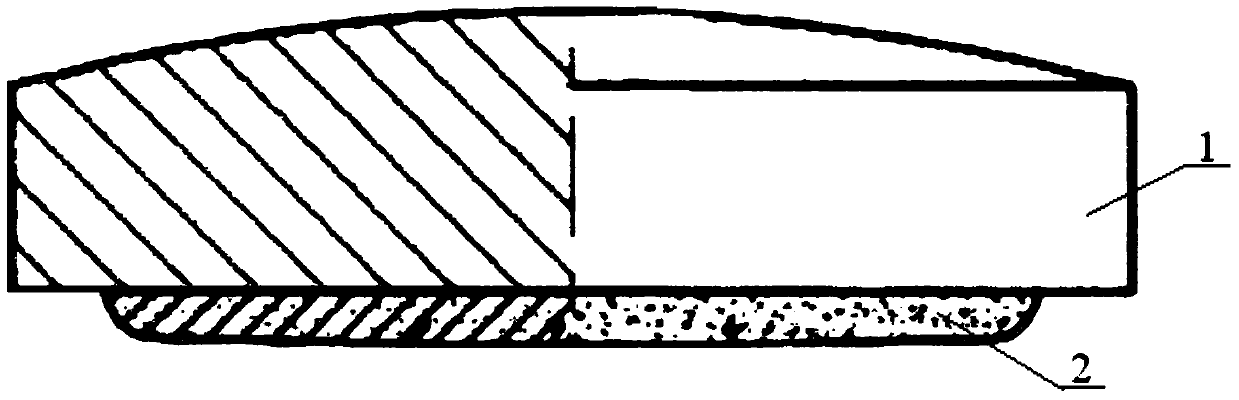

A silver-based electrical contact that can be directly soldered and its manufacturing method

An electric contact and silver-based technology, which is applied in the field of brazing, can solve the problems that silver-based electric contacts cannot be directly brazed, achieve automatic and standardized welding, significantly improve industrial application value, and achieve high welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of paste fluid for brazing composite materials:

[0025] Bond 10 parts by mass of flux (you can choose FB102 silver flux produced by Shanghai Tiangu Welding Equipment Co., Ltd.), 7 parts by mass of binder (you can choose Handy Flo 130 produced by Lukes Brazing Materials (Suzhou) Co., Ltd. agent), 8 parts by mass of curing agent (the epoxy resin curing agent produced by Shandong Deyuan Epoxy Technology Co., Ltd. can be selected) and 75 parts by mass of brazing alloy powder are mixed, and stirred under vacuum until it becomes a paste-like fluid (the viscosity value is 100,000 centipoise); the brazing alloy powder is composed of 7.5wt% Ni, 8.2wt% Sn, 6.0wt% P and a balance of Cu;

[0026] 2. Print the obtained paste fluid on the welding surface of the silver tin oxide alloy electrical contact with a dispenser;

[0027] 3. Sintering the silver-tin oxide alloy electrical contacts printed with the paste fluid at 150° C. under the protection of an inert gas (pr...

Embodiment 2

[0031] 1. Preparation of paste fluid for brazing composite materials:

[0032] 7.5 parts by mass of flux (FB102 silver flux produced by Shanghai Tiangu Welding Equipment Co., Ltd. can be selected), 10 parts by mass of binder (Handy Flo 130 produced by Lukes Brazing Materials (Suzhou) Co., Ltd. can be used for bonding) agent), 12.5 parts by mass of curing agent (the epoxy resin curing agent produced by Shandong Deyuan Epoxy Technology Co., Ltd. can be selected) and 70 parts by mass of brazing alloy powder are mixed, and stirred under vacuum until it becomes a paste-like fluid (viscosity value is 250,000 centipoise); the brazing alloy powder is made up of 6.0wt% Ni, 9.0wt% Sn, 7.0wt% P and balance Cu;

[0033] 2. Print the obtained paste fluid on the welding surface of the silver tin oxide alloy electrical contact with a dispenser;

[0034] 3. Sintering the silver tin oxide alloy electrical contact printed with the paste fluid at 120° C. under the protection of an inert gas (pr...

Embodiment 3

[0038] 1. Preparation of paste fluid for brazing composite materials:

[0039] Bond 5 parts by mass of flux (you can choose FB102 silver flux produced by Shanghai Tiangu Welding Equipment Co., Ltd.), 15 parts by mass of binder (you can choose Handy Flo 130 produced by Lukes Brazing Materials (Suzhou) Co., Ltd. agent), 15 parts by mass of curing agent (the epoxy resin curing agent produced by Shandong Deyuan Epoxy Technology Co., Ltd. can be selected) and 65 parts by mass of brazing alloy powder are mixed, and stirred under vacuum until it becomes a paste-like fluid (viscosity value is 400,000 centipoise); the brazing alloy powder is made up of 8.0wt% Ni, 7.0wt% Sn, 5.0wt% P and balance Cu;

[0040] 2. Print the obtained paste fluid on the welding surface of the silver tin oxide alloy electrical contact with a dispenser;

[0041] 3. Sintering the silver-tin oxide alloy electrical contacts printed with the paste fluid at 180° C. under the protection of an inert gas (preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com