Method for adopting aluminum or aluminum alloy to directly braze aluminum nitride ceramics

A technology of aluminum nitride ceramics and aluminum alloys, applied in the field of ceramic processing, can solve the problems of low bonding strength between Al and Al alloys and AlN ceramics, lower joint quality and performance, and unsatisfactory brazing joint strength, etc., to achieve high brazing The effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

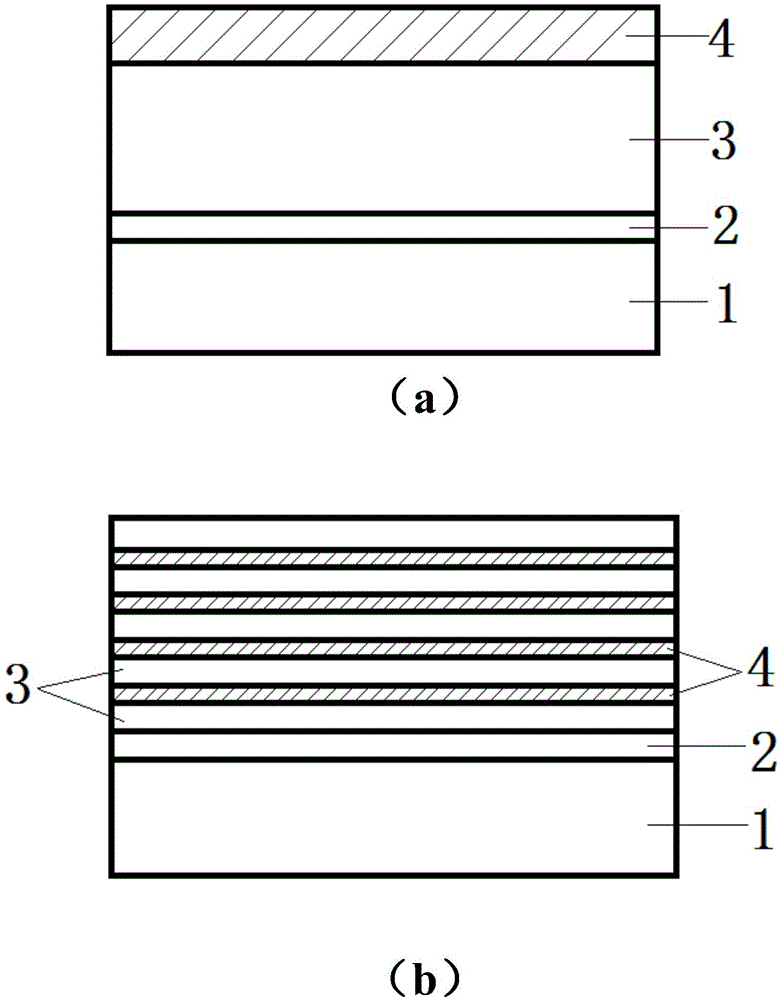

Method used

Image

Examples

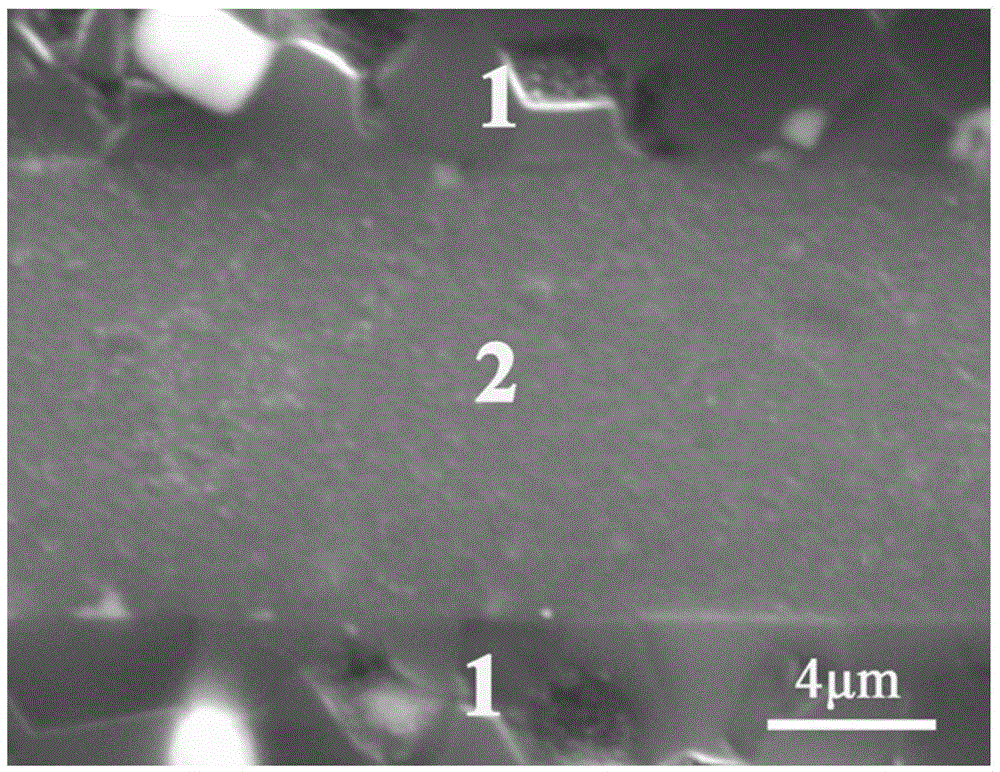

Embodiment 1

[0038] A pure Al coating was plated on the AlN ceramic surface with a thickness of 7 μm. The heating temperature of vacuum brazing was 670° C. and kept for 10 minutes. The joint shear strength obtained after brazing of this coating is 104 MPa. The shear strength of brazed joints is measured by the national standard GB11363-89 "Test Method for Strength of Brazed Joints", the same below.

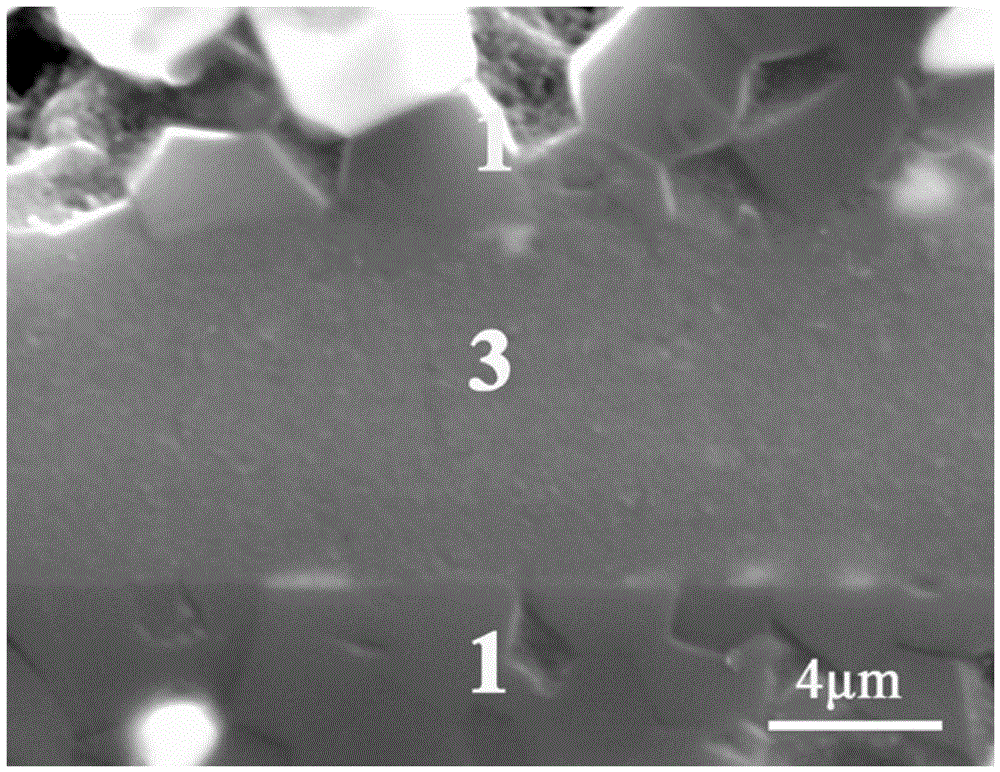

Embodiment 2

[0040] The Al-Cu coating is plated on the AlN ceramic surface. The structure of the coating is to first plate an Al layer with a thickness of 7 μm, and then plate a Cu layer with a thickness of 200 nm on the surface, so that the double-layer coating can be melted to obtain Al-3.8at.%Cu alloy solder, the heating temperature of vacuum brazing is 670°C and the temperature is kept for 10 minutes. The joint shear strength obtained after brazing is 165MPa.

Embodiment 3

[0042] Al-Cu coating is plated on the AlN ceramic surface. The structure of the coating is to plate a 100nm thick Al bottom layer first, and then plate a Cu layer with a thickness of 500nm, so that the multilayer coating can be melted to obtain Al-9.4at .% Cu alloy brazing filler metal, on the surface of the Cu layer, an Al layer with a thickness of 7 μm is plated, and the heating temperature for vacuum brazing is 670° C. and kept for 10 minutes. The joint shear strength obtained after brazing is 95MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Joint shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com