Method for connecting ceramic cover for antenna and metal connecting ring

A ceramic antenna and metal connection technology, which is applied in metal processing equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of residual stress rise, ceramic fracture, and ceramic brittleness, etc., to reduce microcracks and relieve residual Stress, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

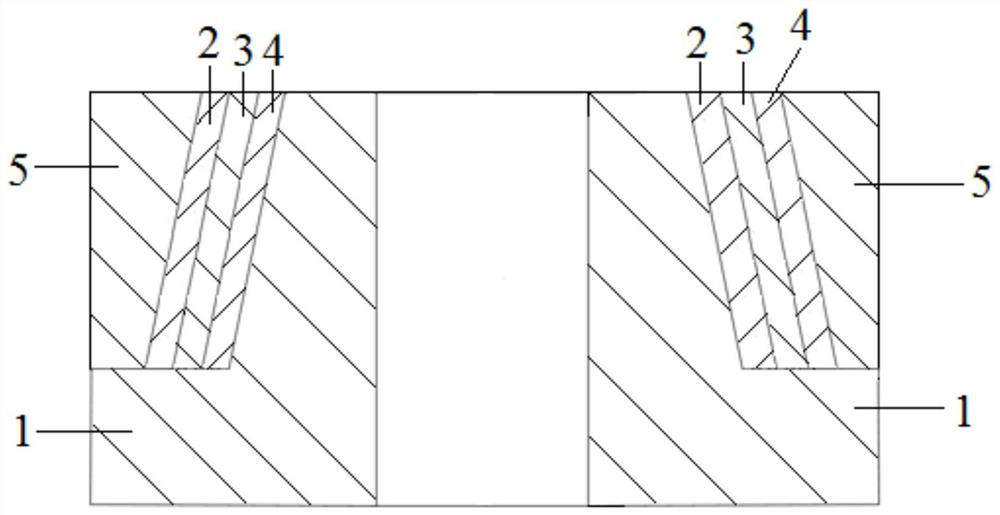

[0028] Specific implementation mode 1: This implementation mode is a connection method between a ceramic radome and a metal connecting ring, which is specifically carried out according to the following steps:

[0029] 1. Clean the Invar alloy connecting ring with absolute ethanol and acetone in sequence to remove the oil stains on the pre-welded surface;

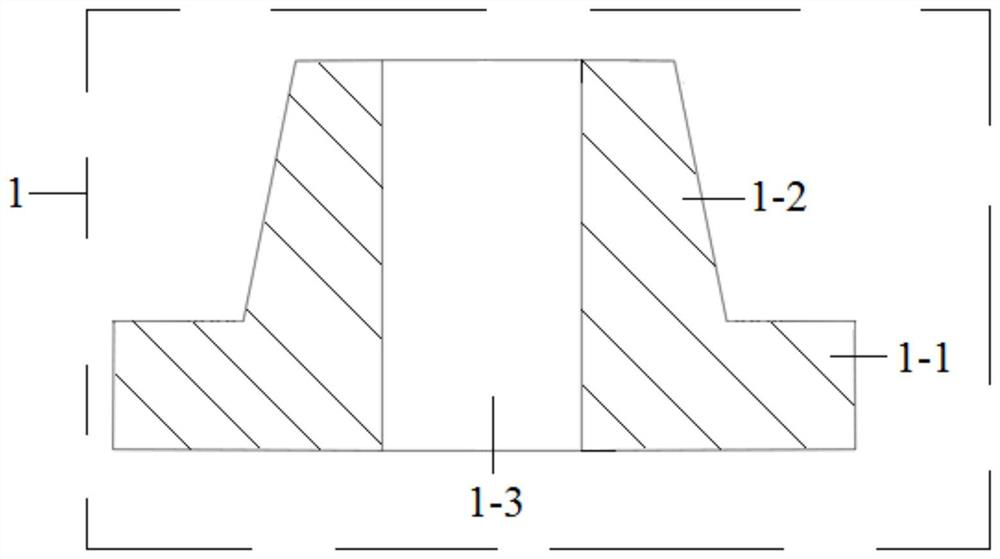

[0030] The center of the Invar alloy connecting ring is a through hole, the upper part of the Invar alloy connecting ring is a hollow circular truncated structure, and the diameter of the upper end is smaller than the diameter of the lower end; the lower part of the Invar alloy connecting ring is a hollow cylinder structure; the upper part of the Invar alloy connecting ring The outer diameter of the bottom end is smaller than the outer diameter of the lower part of the Invar alloy connecting ring;

[0031] Second, the porous Si 3 N 4 Wipe the surface of the ceramic radome with cotton to remove the dust on the surface; the ...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 3, put it in an oven for drying at 40°C. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the thickness of the inner brazing filler metal described in step 3 is 50 μm-100 μm. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com