Method for directly brazing aluminum oxide ceramic by adopting zirconium brazing filler metal

An alumina ceramic and brazing technology, applied in the field of ceramics, can solve the problems of unsatisfactory brazing joint strength, reduced joint quality and performance, low ceramic bonding strength, etc., achieve controllable composition and structure, improve corrosion resistance, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for directly brazing alumina ceramics with zirconium brazing filler metal includes the following steps:

[0035] (a) Al 2 O 3 The surface to be brazed of the ceramic sheet (30×30×0.8mm) is polished, and cleaned after polishing to reduce its surface roughness;

[0036] (b) Using magnetron sputtering method to plate the Zr elemental coating as a solder on the polished ceramic surface, the thickness of the Zr elemental coating is 7μm;

[0037] (c) Place two pieces of plated alumina ceramics opposite each other on the coated surface and apply a pressing force, then load them into a vacuum furnace, and evacuate the vacuum furnace chamber to a pressure lower than 10 -1 Pa, and keep the air pressure not higher than this value during subsequent heating;

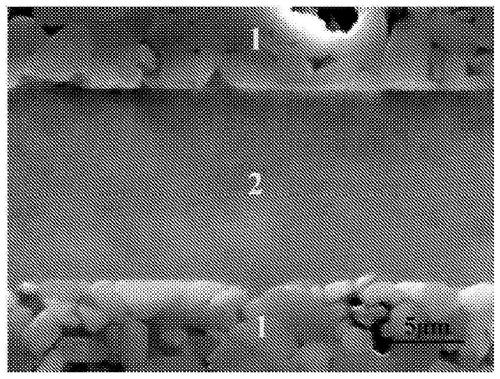

[0038] (d) Carry out vacuum heating and brazing, and the brazing temperature is 2200℃. Heat to the brazing temperature and keep it for 10 minutes, then take it out with the furnace cooling, and obtain the brazing joint with th...

Embodiment 2

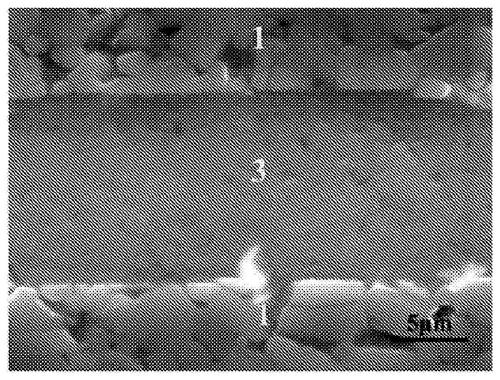

[0041] A method of directly brazing alumina ceramics using zirconium brazing filler metal, except that in step (b), a zirconium alloy coating is plated on the polished ceramic surface. The coating sequence of the zirconium alloy coating is: first polishing The ceramic surface is coated with a Zr elemental layer with a thickness of 7μm, and then a Cu layer with a thickness of 100nm is plated on the surface of the Zr elemental layer. The rest are the same as in Example 1, to obtain Zr-2.0at.%Cu brazing seam with oxidation For brazing joints directly connected to aluminum ceramics, use Hitachi S-3400n scanning electron microscope (SEM) to observe the brazing joints, such as figure 2 As shown, 1 is Al 2 O 3 The ceramic layer, 3 is a Zr-2.0at.%Cu alloy brazing seam layer. It can be seen that each brazing seam presents a dense and full as-cast structure, and there are few brazing defects such as end penetration and pores. The brazing seam and the ceramic are formed Good metallurgica...

Embodiment 3

[0043] A method of directly brazing alumina ceramics using zirconium brazing filler metal, except that in step (b), a zirconium alloy coating is plated on the polished ceramic surface. The coating sequence of the zirconium alloy coating is: first polishing The ceramic surface is plated with a 100nm thick Zr elemental underlayer, followed by a Cu layer with a thickness of 1μm, and a Zr elemental layer with a thickness of 7µm is plated on the Cu layer. The rest are the same as in Example 1, to obtain Zr- 15.0at.%Cu brazing joints directly connected with alumina ceramics, each brazing joint presents a dense and full as-cast structure, and there are few brazing defects such as end penetration and pores. The brazing joints and ceramics form a good metallurgy Bonded, and the shear strength is 127MPa, and the toughness is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com