Wire scratch preventing mechanism for wire winder

A wire winding machine and anti-scratch technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as scratches on enameled wires, reducing the efficiency and service life of motors, and burning motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present invention, and other embodiments obtained by those skilled in the art without creative efforts all belong to the protection scope of the present invention.

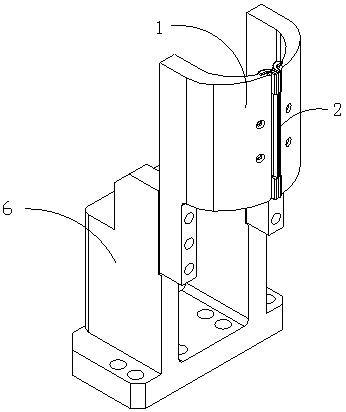

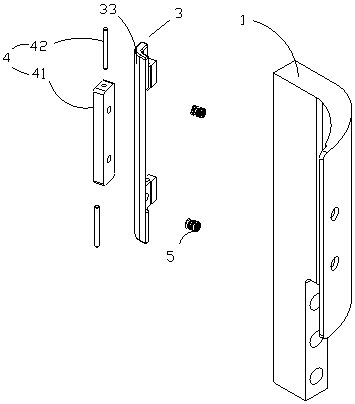

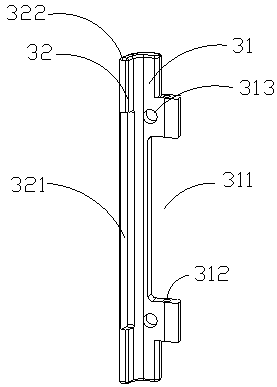

[0027] Such as Figure 1-3 The anti-scratch wire mechanism of the winding machine shown in the present invention mainly includes an arc-shaped wire block 1 that matches the circular radian of the stator, and a shrapnel assembly is installed at the wire-entry slot of the arc-shaped wire block 1 corresponding to the stator. 2. The shrapnel assembly 2 mainly includes an anti-scratch wire stopper 3 that can be inserted into the inlet slot of the stator, and a fixing part 4 for fixing the anti-scratch wire stopper 3 on the arc-shaped wire block 1, so that the scratch-resistant wire The stopper 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com