Plastic bellows forming machine sliding seat running track

A sliding seat and bellows technology, which is applied in the production field of plastic corrugated pipes, can solve problems such as mutual interference failure of sliding seats and increase in the degree of freedom of sliding seats, and achieve the effect of improving operating efficiency and optimizing processing and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

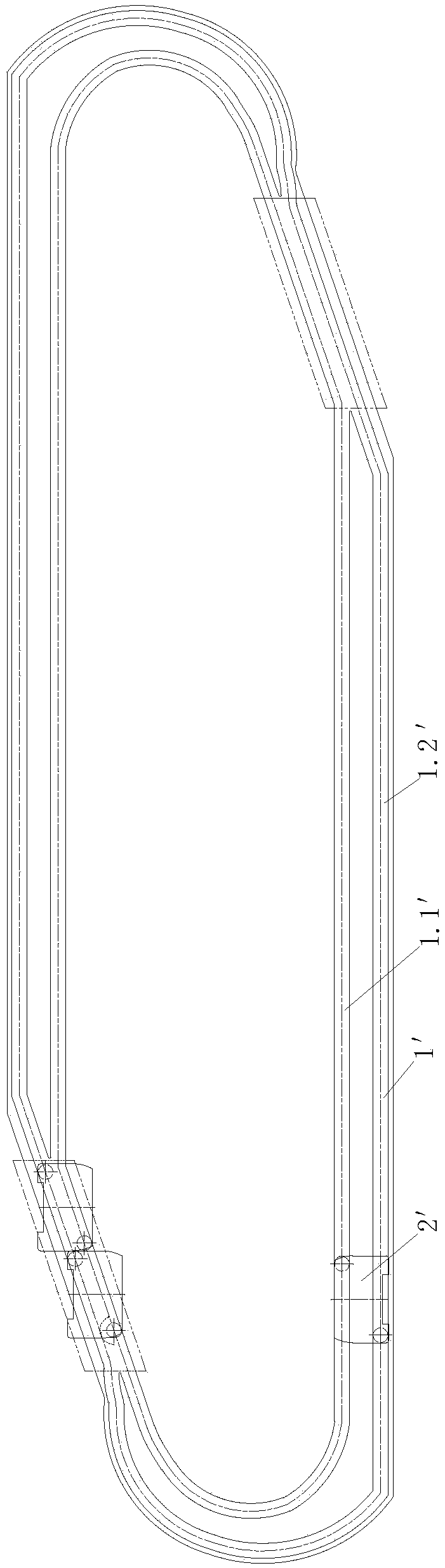

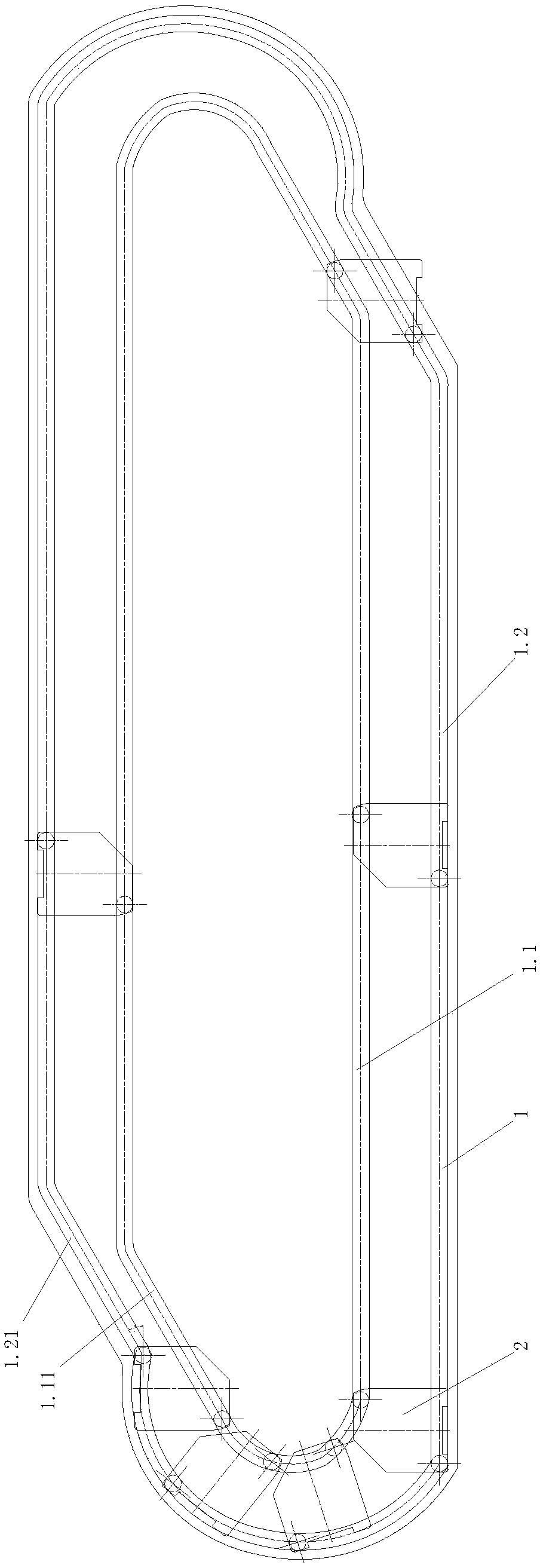

[0017] Such as figure 2 As shown, the present invention includes a running track 1 and a sliding seat 2; the running track 1 includes an inner track 1.1 and an outer track 1.2; the inner and outer tracks respectively include an inner inclined section 1.11 and an outer inclined section 1.21; Bearings not fully shown; the lengths of the inner inclined section 1.11 and the outer inclined section 1.21 are equal, both of which are twice the width of the sliding seat 2; the inclined angles of the inner inclined section 1.11 and the outer inclined section 1.21 are both 30°-35°, The inner inclined section 1.11 and the outer inclined section 1.21 are parallel to each other and misaligned with each other, and the length of the overlapping sections of mutual misalignment is equal to half of the length of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com