Aluminum-plastic composite film with excellent heat sealability and tearing resistance

An aluminum-plastic composite film and tear-resistant technology, applied in the field of aluminum-plastic composite film, can solve problems such as difficulty in obtaining aluminum-plastic composite film, and achieve the effect of good super-hydrophobic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

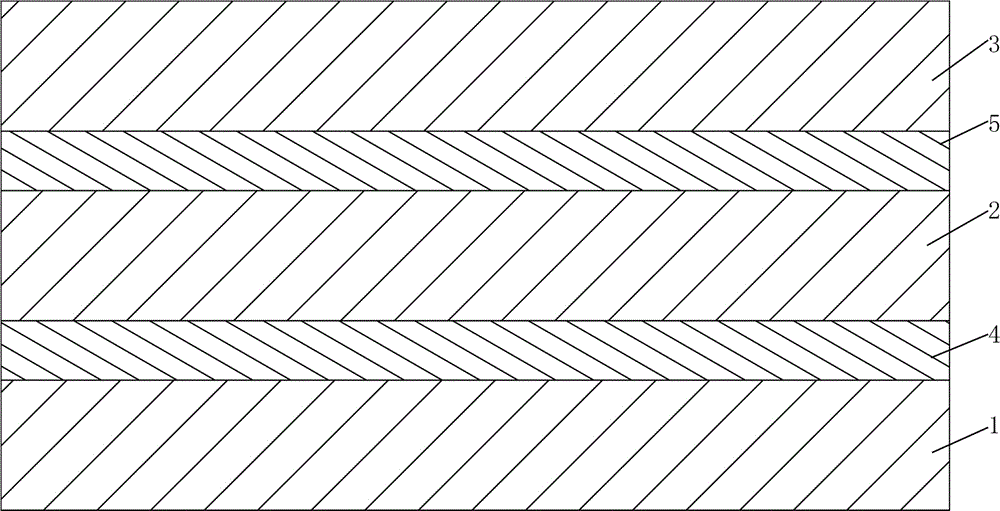

[0045] refer to figure 1 , the aluminum-plastic composite film with good heat-sealing performance and tear resistance of this embodiment includes a cast polypropylene film layer 1, an aluminum foil layer 2 and a biaxially oriented polyamide film bonded together from the inside to the outside in sequence Layer 3; the degree of orientation f of the machine direction of the cast polypropylene film layer 1 av is 0.2. In this embodiment, the cast polypropylene film layer 1 is connected to the aluminum foil layer 2 through the first adhesive layer 4 , and the biaxially stretched polyamide film layer 3 is connected to the aluminum foil layer 2 through the second adhesive layer 5 . The first adhesive layer 4 can use polyolefin hot melt adhesive, and the second adhesive layer 5 can use polyurethane adhesive. The thickness of the biaxially stretched polyamide film layer 3 is 30 μm, the thickness of the cast polypropylene film layer 1 is 50 μm, and the thickness of the aluminum foil la...

Embodiment 2

[0052] refer to figure 1 , the aluminum-plastic composite film with good heat-sealing performance and tear resistance of this embodiment includes a cast polypropylene film layer 1, an aluminum foil layer 2 and a biaxially oriented polyamide film bonded together from the inside to the outside in sequence Layer 3; the degree of orientation f of the machine direction of the cast polypropylene film layer 1 av is 0.5. In this embodiment, the cast polypropylene film layer 1 is connected to the aluminum foil layer 2 through the first adhesive layer 4 , and the biaxially stretched polyamide film layer 3 is connected to the aluminum foil layer 2 through the second adhesive layer 5 . The first adhesive layer 4 can use polyolefin hot melt adhesive, and the second adhesive layer 5 can use polyurethane adhesive. The thickness of the biaxially stretched polyamide film layer 3 is 25 μm, the thickness of the cast polypropylene film layer 1 is 55 μm, and the thickness of the aluminum foil la...

Embodiment 3

[0059] refer to figure 1 , the aluminum-plastic composite film with good heat-sealing performance and tear resistance of this embodiment includes a cast polypropylene film layer 1, an aluminum foil layer 2 and a biaxially oriented polyamide film bonded together from the inside to the outside in sequence Layer 3; the degree of orientation f of the machine direction of the cast polypropylene film layer 1 av is 0.1. In this embodiment, the cast polypropylene film layer 1 is connected to the aluminum foil layer 2 through the first adhesive layer 4 , and the biaxially stretched polyamide film layer 3 is connected to the aluminum foil layer 2 through the second adhesive layer 5 . The first adhesive layer 4 can use polyolefin hot melt adhesive, and the second adhesive layer 5 can use polyurethane adhesive. The thickness of the biaxially stretched polyamide film layer 3 is 30 μm, the thickness of the cast polypropylene film layer 1 is 40 μm, and the thickness of the aluminum foil la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com