Separated super-hydrophilic/super-hydrophobic surface enhanced Raman scattering substrate and preparation method thereof

A surface-enhanced Raman and Raman-enhanced scattering technology is applied in Raman scattering, material analysis, material excitation analysis, etc., to achieve the effects of reducing the cost of use, improving detection efficiency, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

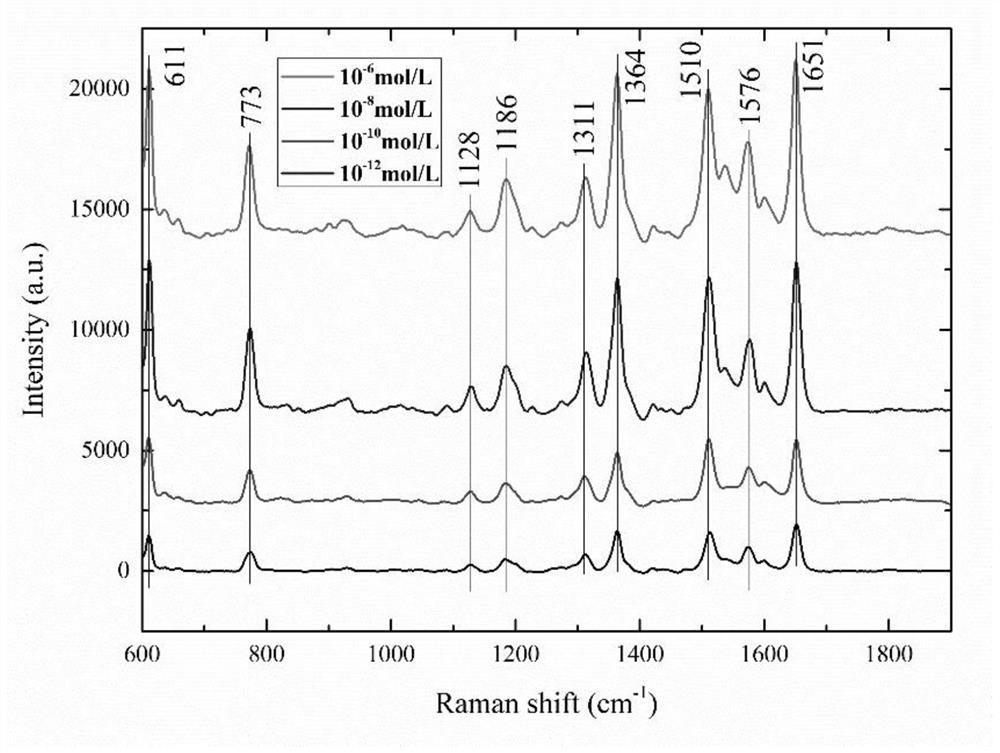

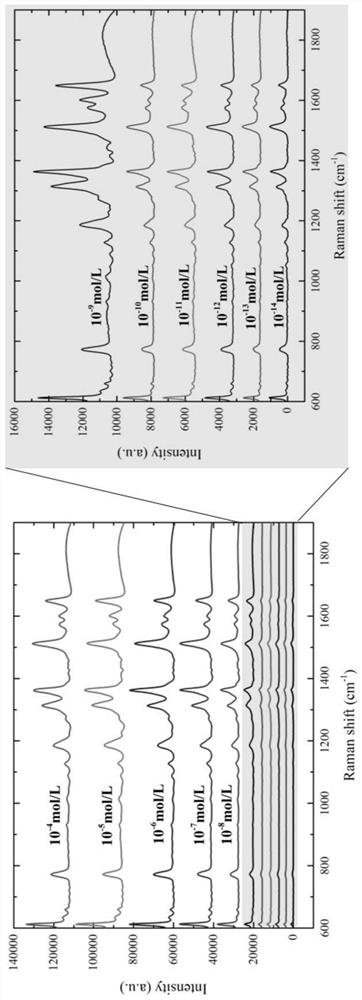

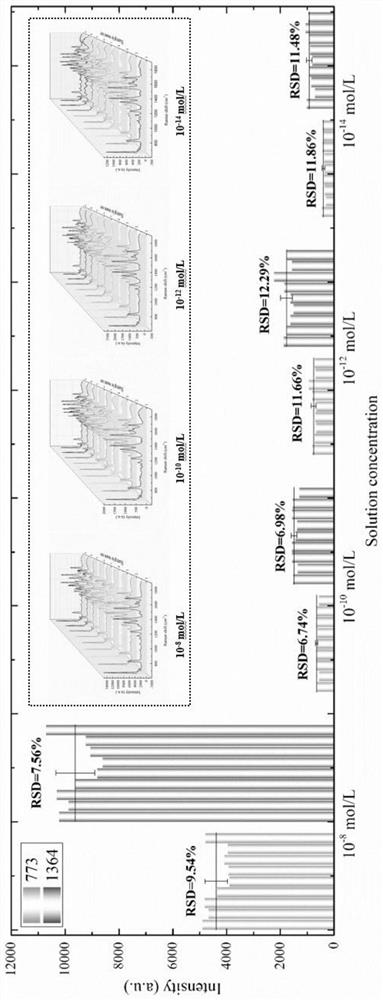

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing the separated superphilic / superhydrophobic surface-enhanced Raman scattering substrate, comprising the following steps:

[0049] 1) The transition metal is ablated and irradiated with a laser to obtain a super-hydrophilic surface-enhanced Raman scattering substrate;

[0050] 2) The laser is used to sequentially drill holes and ablate the metal to obtain metals containing micro-nano structures;

[0051] 3) performing oxidation treatment and fluorination treatment on the metal in step 2) sequentially to obtain a superhydrophobic template with holes;

[0052] 4) The superhydrophilic surface-enhanced Raman scattering substrate and the superhydrophobic template with holes are clamped to obtain a separated superphilic / superhydrophobic surface-enhanced Raman scattering substrate.

[0053] In step 1) and step 2) of the present invention, the laser is preferably a femtosecond laser, a picosecond laser or a nanosecond la...

Embodiment 1

[0062] Silver flakes with a length, width and thickness of 10 mm, 25 mm and 0.1 mm were ultrasonically cleaned in alcohol for 3 minutes and then dried with nitrogen gas with a purity of 99.99%. A femtosecond laser is used for ablation irradiation on the surface of the silver sheet. The average power of the laser is 6W, and the path of the dot matrix is scanned, and the scanning time is 0.05ms. After the laser ablation irradiation is completed, the silver sheet is rinsed with absolute ethanol, and then the residual absolute ethanol liquid is blown off with nitrogen gas with a purity of 99.99%. At the same time, it is dried to obtain a super-hydrophilic silver-based substrate with a contact angle of ~0°. The surface-enhanced Raman scattering substrate, the surface of the super-hydrophilic surface-enhanced Raman scattering substrate contains an array of micro-pit arrays, the period of the micro-pit array is 20 μm, and the depth is 5 μm. nanoprotrusions.

[0063] Copper sheets ...

Embodiment 2

[0068] Silver sheets with a length, width and thickness of 10 mm, 25 mm and 0.1 mm were ultrasonically cleaned in alcohol for 5 min, and then dried with nitrogen with a purity of 99.99%. A picosecond laser is used for ablation irradiation on the surface of the silver sheet. The average power of the laser is 35W, and the spot scan time is 10 ms according to the path of the dot matrix. After the laser ablation irradiation is completed, the silver sheet is rinsed with absolute ethanol, and then the residual absolute ethanol liquid is blown off with nitrogen gas with a purity of 99.99%. At the same time, it is dried to obtain a super-hydrophilic silver-based substrate with a contact angle of ~0°. The surface-enhanced Raman scattering substrate, the surface of the super-hydrophilic surface-enhanced Raman scattering substrate contains an array of micro-pit arrays, the period of the micro-pit array is 50 μm, and the depth is 13 μm. nanoprotrusions.

[0069] Copper sheets with a leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com