A kind of anti-mechanical shock superhydrophobic rubber and preparation method thereof

A mechanical shock and super-hydrophobic technology, which is applied in the field of mechanical shock-resistant super-hydrophobic rubber and its preparation, can solve the problems of practical application limitations, weak binding force between hydrophobic substances and substrates, and decline in super-hydrophobic performance, so as to achieve easy operation of the process, Excellent superhydrophobic stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of a kind of anti-mechanical shock superhydrophobic rubber of the present invention, at first take butyl rubber (IIR) and ethylene vinyl acetate (EVA) as matrix, in double crosslinking agent dicumyl peroxide (DCP) and sulfur ( S) and the foaming agent azodicarbonamide (AC), the porous rubber block material is obtained through the rubber mixing, milling, and vulcanization processes, and then the rubber skin is removed and the surface is polished with sandpaper to obtain a super Hydrophobic rubber material. Specific steps are as follows:

[0028] Preparation of S1, IIR / EVA rubber

[0029] 40-70 parts by weight of IIR and 30-60 parts by weight of EVA are used as the matrix, 15-30 parts by weight of white carbon black and 3-6 parts by weight of paraffin are used as fillers, and 0.2-0.7 parts by weight of diisopropyl peroxide Benzene and 0.4 to 0.7 parts by weight of sulfur are used as crosslinking agents, 5 to 15 parts by weight of zinc oxide and 1 ...

Embodiment 1

[0035] step 1

[0036] 70 parts by weight of butyl rubber (IIR) and 30 parts by weight of ethylene vinyl acetate (EVA) as a matrix, 15 parts by weight of white carbon black and 5 parts by weight of paraffin as fillers, 0.4 parts by weight of diisoperoxide The sulfur of propylbenzene and 0.6 weight part is as crosslinking agent, the zinc oxide of 5 weight parts and the stearic acid of 3 weight parts are as foaming aid, the azodicarbonamide of 2 weight parts is as blowing agent, at temperature Mix evenly in an internal mixer at 80°C; then process it into a 12mm thick rubber compound by adjusting the open mixer. Finally, the IIR / EVA compound was vulcanized in a vulcanizer at 170°C for 450s to make it cross-linked and formed, and cooled at room temperature to obtain a porous rubber material.

[0037] step 2

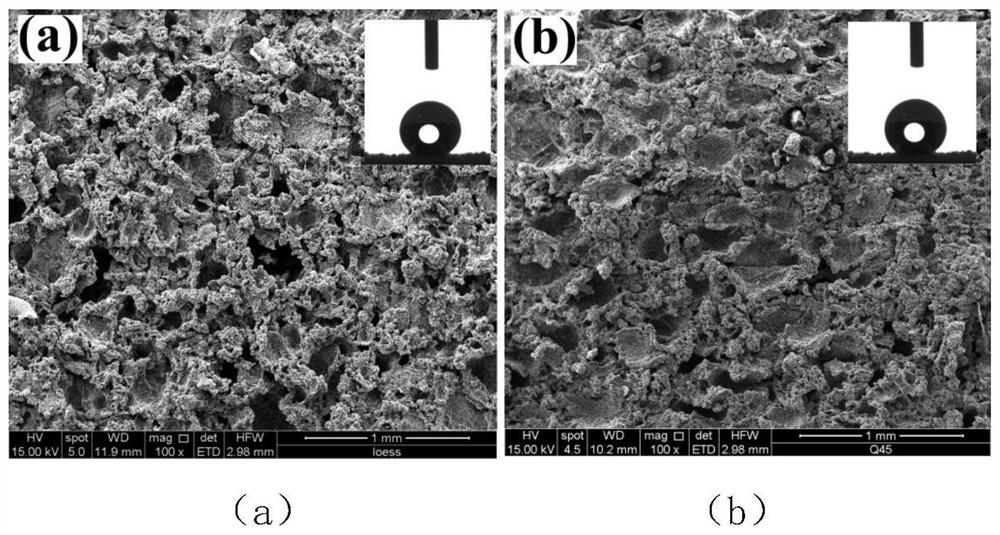

[0038] Remove the rubber skin and grind the rubber surface 100 times with 600 mesh sandpaper to obtain superhydrophobic rubber. Its surface contact angle is 159.5 °, after...

Embodiment 2

[0040] step 1

[0041]60 parts by weight of butyl rubber (IIR) and 40 parts by weight of ethylene vinyl acetate (EVA) as a matrix, 25 parts by weight of white carbon black and 3 parts by weight of paraffin as fillers, 0.5 parts by weight of diisoperoxide The sulfur of propylbenzene and 0.7 weight part is as crosslinking agent, the zinc oxide of 8 weight parts and the stearic acid of 5 weight parts are as foaming aid, the azodicarbonamide of 2.5 weight parts is as blowing agent, at temperature Mix evenly in an internal mixer at 90°C; then process it into an 8mm thick rubber compound by adjusting the open mixer. Finally, the IIR / EVA compound was vulcanized in a vulcanizer at 165°C for 450s to make it cross-linked and formed, and cooled at room temperature to obtain a porous rubber material.

[0042] step 2

[0043] Remove the rubber skin and grind the rubber surface 350 times with 500 mesh sandpaper to obtain superhydrophobic rubber. Its surface contact angle is 160.4°, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com