Super-hydrophobic/super-oleophilic multilevel structure polyether sulfone oil-water separation membrane and preparation method thereof

A technology of oil-water separation membrane and polyethersulfone membrane, which is applied in separation methods, permeation/dialysis water/sewage treatment, liquid separation, etc. It can solve the problems of unsuitable promotion, high cost and low flux, and achieve excellent superhydrophobicity properties, excellent corrosion resistance, effects of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

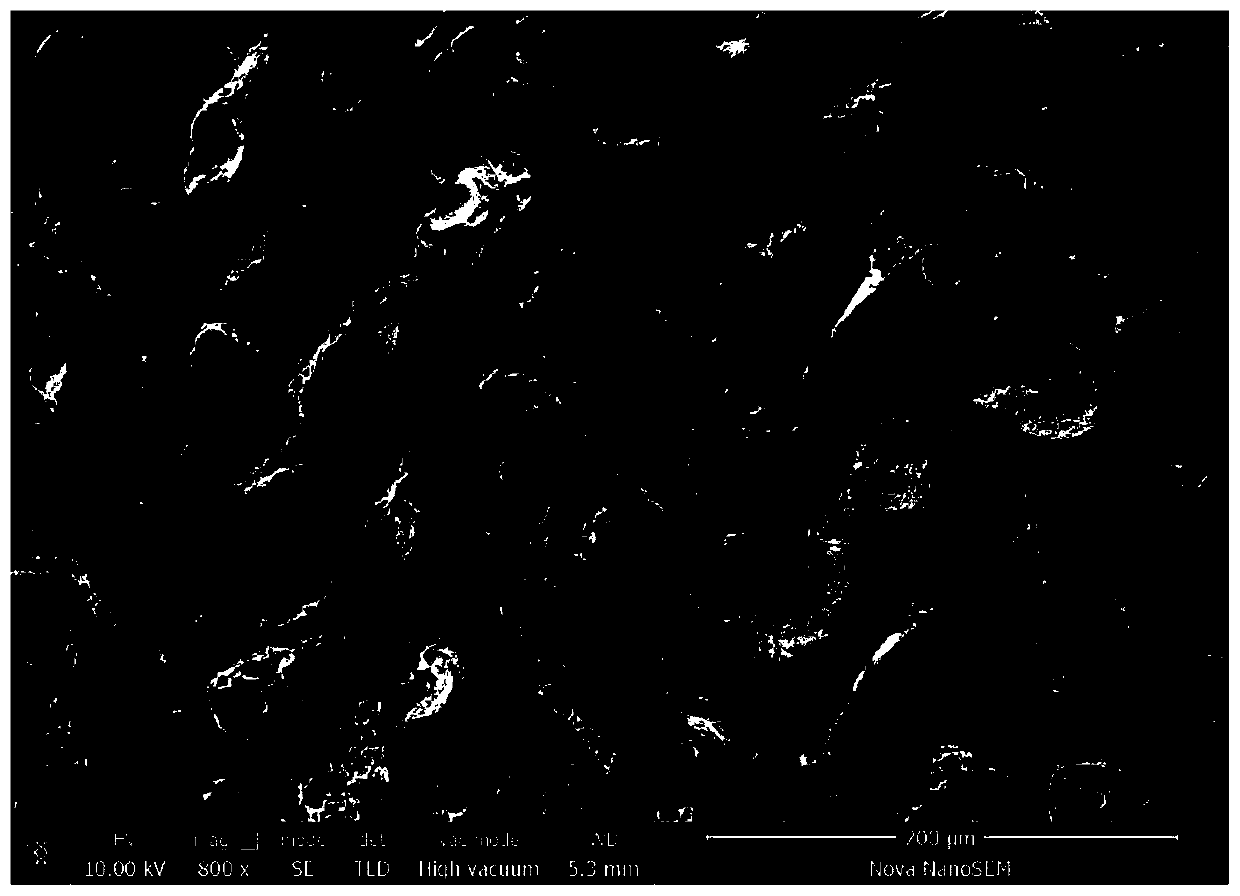

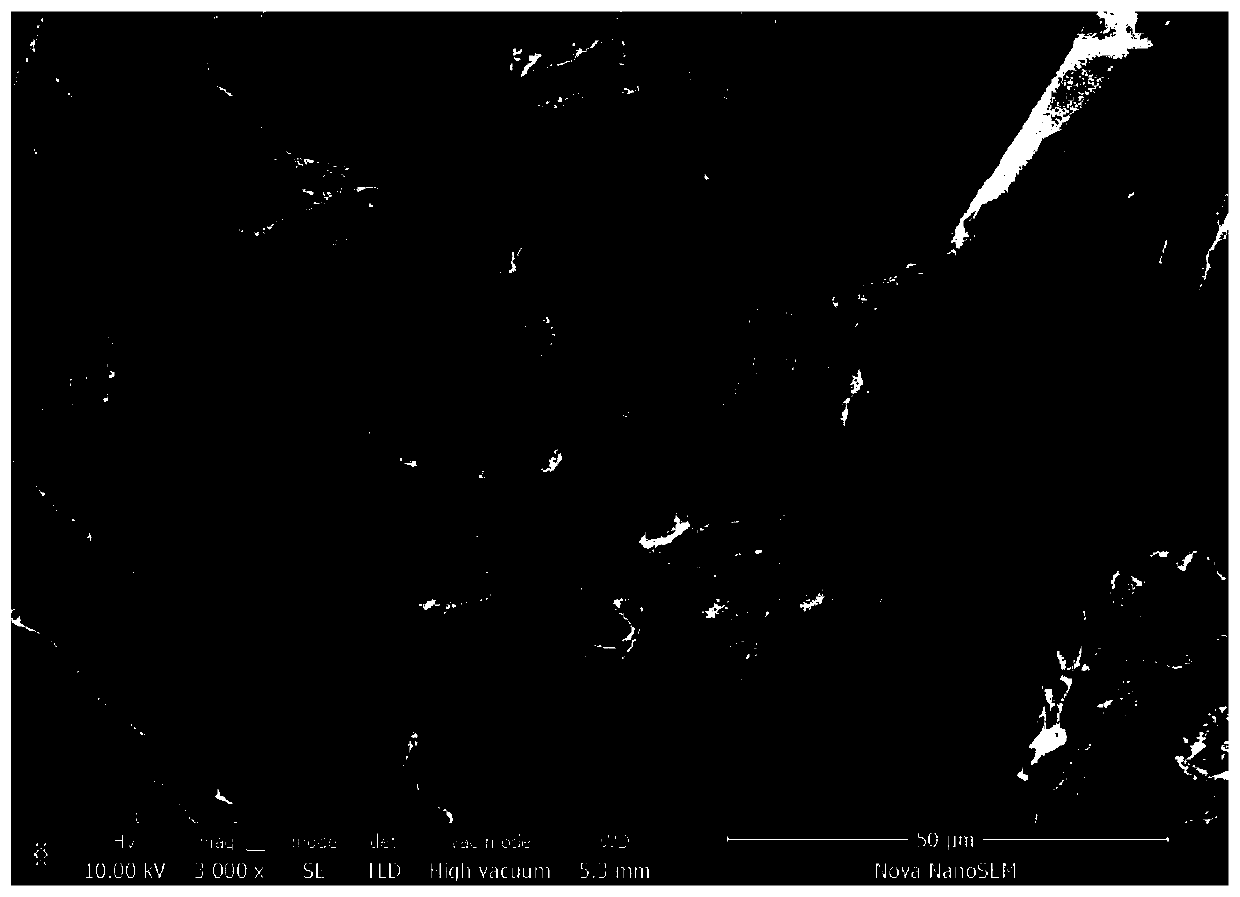

[0025] 1) Add 2.2g of polyethersulfone (melt index 0.5g / 10min), 0.8g of silica micropowder (particle size 80μm) and 0.4g of polyvinylpyrrolidone into a scale filled with 16.6g of N,N-dimethylformamide In a measuring bottle, heat and stir at 50°C for 1 hour to obtain the casting solution and vacuum degassing, pour the prepared solution on a polytetrafluoroethylene mold with a 1000-mesh filter cloth on the surface, and stand still in the air for 30 seconds Transfer the mold together with the filter cloth to distilled water for exchange for 6 hours, remove the filter cloth from the mold and peel off the membrane from the filter cloth to obtain an asymmetric single-sided silicon dioxide-containing porous polyethersulfone membrane.

[0026] 2) Add 0.727g of hexadecyltrimethoxysilane into a beaker filled with a mixture of 30mL of ammonia water and ethanol at pH=8, immerse the porous polyethersulfone membrane obtained in step 1), and hydrolyze at 60°C After 1h, take it out and rinse ...

Embodiment 2

[0029] 1) Add 2.2g of polyethersulfone (melt index 0.6g / 10min), 1.6g of silica micropowder (particle size 70μm) and 0.8g of polyvinylpyrrolidone into a scale filled with 15.4g of N,N-dimethylformamide In a measuring bottle, heat and stir at 60°C for 0.8h to obtain the casting solution and vacuum degassing, pour the prepared solution on a polytetrafluoroethylene mold with a 1000-mesh filter cloth on the surface, let it rest in the air for 40 seconds The mold and the filter cloth were transferred to distilled water for 7 hours, and the filter cloth was removed from the mold and the membrane was peeled off from the filter cloth to obtain an asymmetric single-sided silicon dioxide-containing porous polyethersulfone membrane.

[0030] 2) Add 0.727g of hexadecyltrimethoxysilane into a beaker containing 30mL of ammonia water and ethanol mixture (pH=8), immerse the porous polyethersulfone membrane obtained in step 1), and hydrolyze at 60°C for 1h, After taking it out, rinse it three t...

Embodiment 3

[0033]1) Add 2.4g of polyethersulfone (melt index 0.7g / 10min), 1.2g of silica micropowder (particle size 60μm) and 0.5g of polyvinylpyrrolidone into a scale filled with 15.9g of N,N-dimethylformamide In a measuring bottle, heat and stir at 70°C for 0.7h to obtain the casting solution and vacuum degassing, pour the prepared solution on a polytetrafluoroethylene mold with a 1000-mesh filter cloth on the surface, let it rest in the air for 30 seconds The mold and the filter surface were transferred to distilled water for 8 hours, and the filter cloth was removed from the mold and the membrane was peeled off from the filter cloth to obtain an asymmetric single-side silicon dioxide-containing porous polyethersulfone membrane.

[0034] 2) Add 1.44g of hexadecyltrimethoxysilane into a beaker containing 60mL of ammonia water and ethanol mixture (pH=8.5), immerse the porous polyethersulfone membrane obtained in step 1), and hydrolyze at 70°C for 1h, After taking it out, rinse it three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com