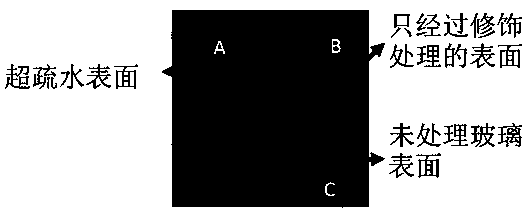

Transparent super-hydrophobic film and preparation method and application thereof

A super-hydrophobic and thin-film technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of uncontrollable microscopic convex structure, weak film-base binding force, poor film-base binding force, etc. , to achieve excellent superhydrophobic properties, reliable methods, and excellent high and low temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

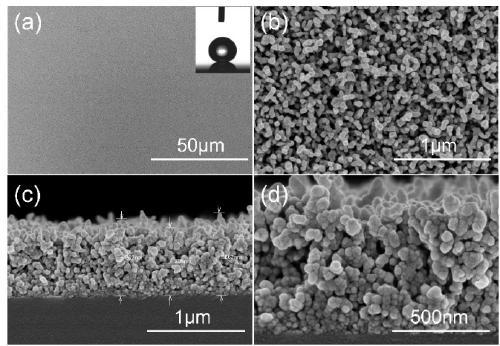

[0045] Embodiment 1: a kind of method for preparing transparent superhydrophobic film, preparation step comprises:

[0046] S1: Zinc thin film is prepared by radio frequency magnetron sputtering system, and then the zinc thin film is annealed to obtain zinc oxide

[0047] film;

[0048] S1a: The substrate is ultrasonically cleaned with acetone, deionized water and absolute ethanol in sequence, and then dried;

[0049] S1b: Under normal temperature conditions, fix the clean substrate in the magnetron sputtering coating chamber, turn on the magnetron sputtering equipment, vacuumize, use the zinc target as the sputtering source, argon as the working gas, and do not add other reaction gases , after the pre-sputtering of the target, the baffle is opened for coating and deposition, and a zinc film supported on the upper surface of the substrate is obtained; the sputtering condition is: the vacuum degree is as low as 4×10 -3 Pa, the working gas pressure is 1.5Pa, the radio frequenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com