Stator hoisting clamp device

A fixture device and hoisting technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of inconvenient operation, unsafe, easily damaged winding copper wires, etc., and achieve the effects of convenient use, reasonable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

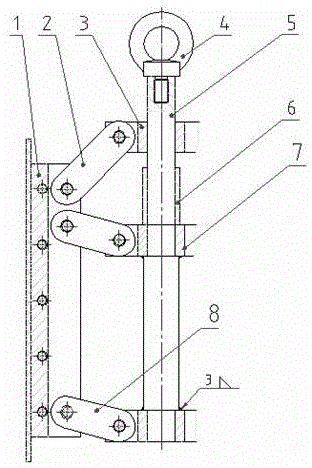

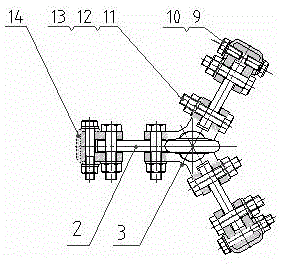

[0010] Such as figure 1 , figure 2 As shown, a stator hoisting fixture device is provided with a strut 1, and the strut 1 is hinged to the bracket 3 and the fixed bracket 7 through the connecting block 2, the small connecting block 8, and the rubber belt 14 is fixed on the strut 1 by the bolt 11. Above, the fixed bracket 7 is welded on the boom 5, and the bracket 3 can slide up and down on the boom 5, thereby changing the diameter of the circle formed by the three braces. When the diameter of the circle increases, the brace 1 and the stator core The inner wall generates pressure, and the stator core is lifted by the friction generated by the rubber belt 14 fixed on the strut 1 with the bolt 9 .

[0011] Said suspension rod 5 of the present invention, the top end is provided with suspension ring screw 4, and fixed support is welded on the suspension shaft 5, and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com