A lotion pump testing machine

A detection machine, emulsion pump technology, applied in pump testing, liquid variable volume machinery, mechanical equipment, etc., can solve the problems of clamping failure, large equipment, and clamping position deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

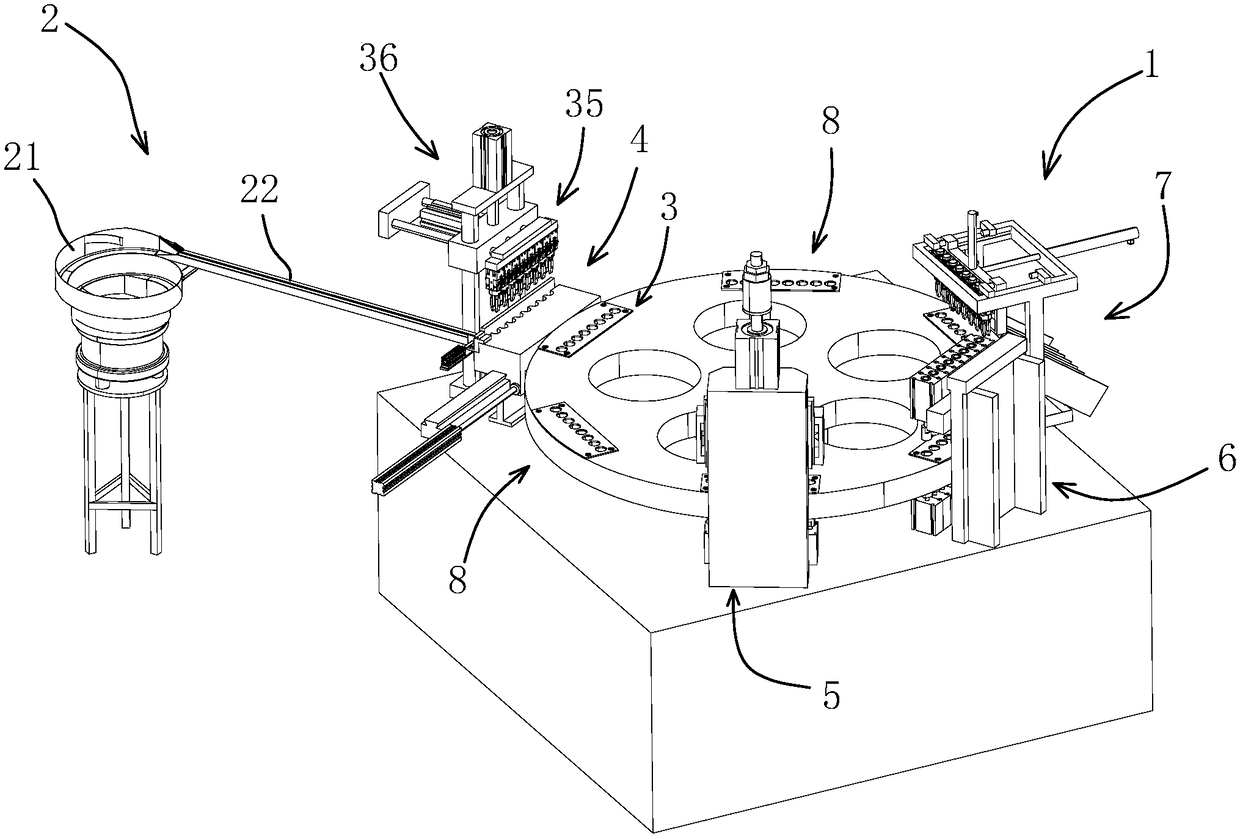

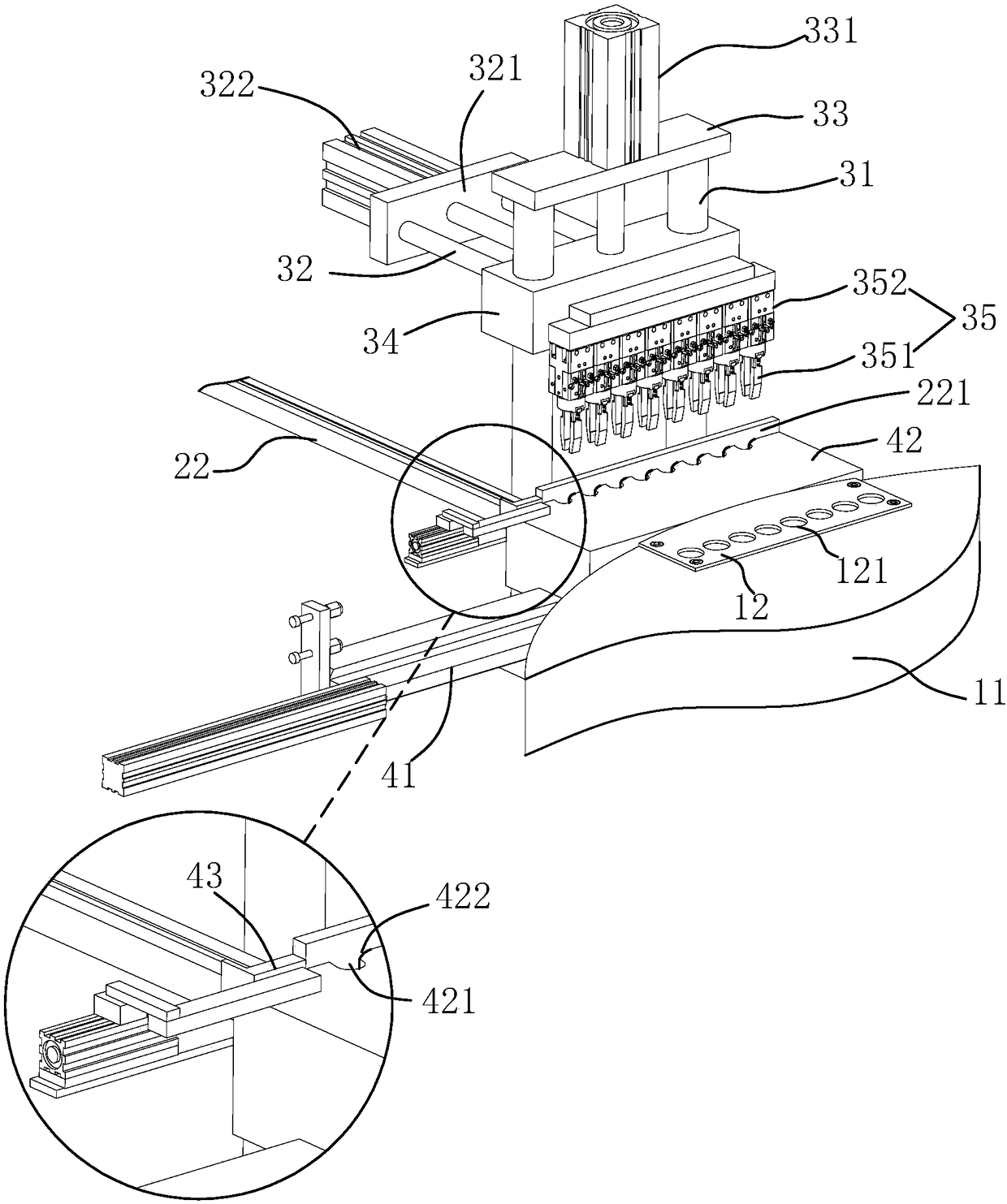

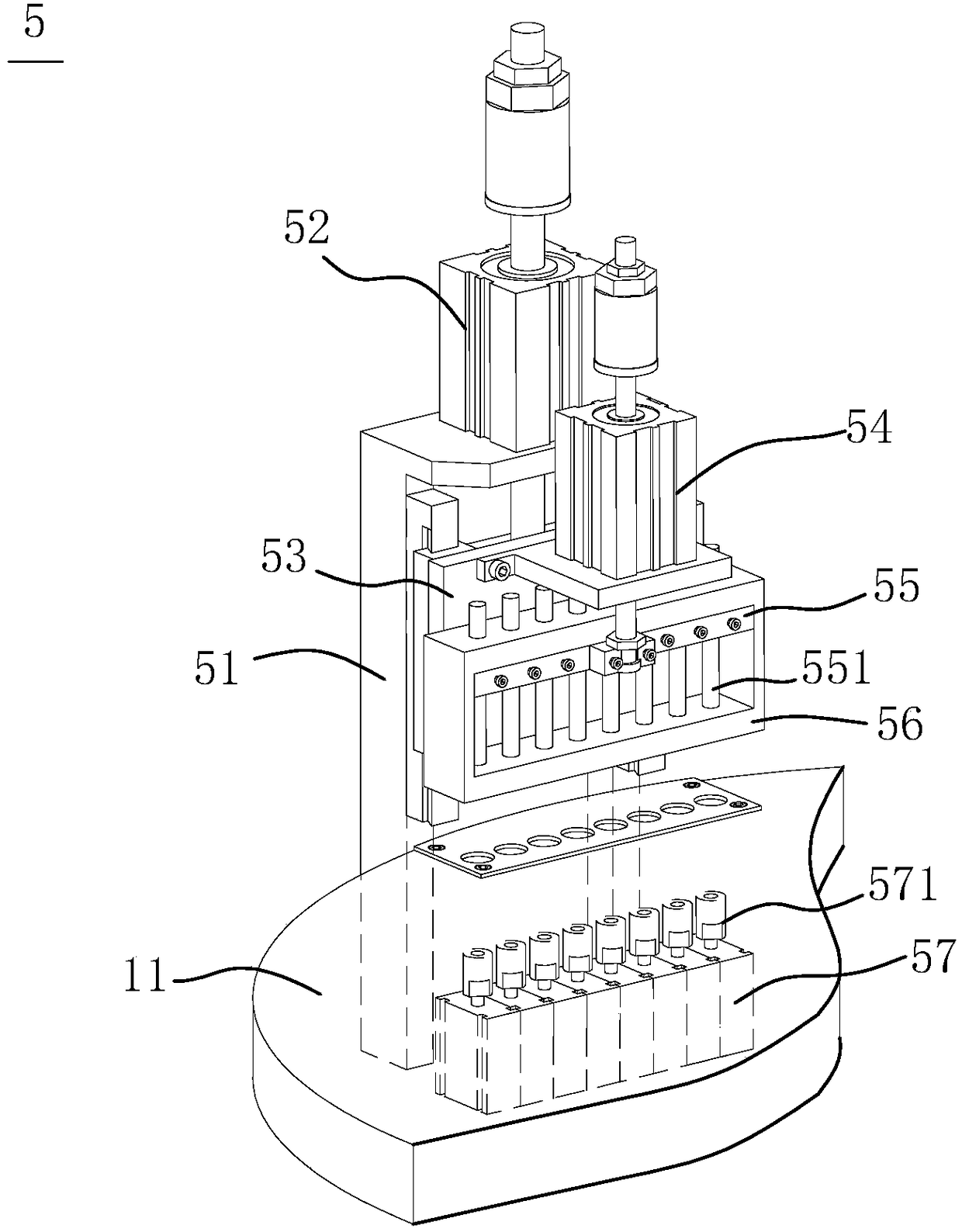

[0035] Please refer to the attached figure 1, a kind of emulsion detection machine, comprises index indexing mechanism 1 and feeding mechanism 2, and wherein feeding mechanism 2 comprises vibrating plate 21 and the feeding track 22 that is connected with vibrating plate 21, and indexing indexing mechanism 1 comprises The indexing plate 11 is evenly provided with the station to be tested 3, the negative pressure detection station 5, the positive pressure detection station 6 and the discharge station 7 on the indexing plate 11. In this embodiment, the station to be tested The two sides of 3 are also provided with undetermined station 8, which is convenient for adding new detection equipment in the subsequent emulsion testing machine, and a pre-positioning mechanism 4 is arranged between the untested station 3 and the feeding track 22.

[0036] Please refer to the attached figure 2 , adopt a vibrating plate 21 and a feeding track 22 among the present embodiment, the indexing in...

Embodiment 2

[0047] The difference from Embodiment 1 is that the end of the feeding track 22 is provided with a semicircular baffle plate 44, and the baffle plate 44 and the feeding track 22 form a feeding port, and the station to be tested 3 is as far as the feeding port. The bottom of the mouth and the trough 121 of the station to be tested 3 corresponds to the feeding port one by one. The pre-positioning mechanism 4 is arranged between the station to be tested 3 and the feed rail 22. The pre-positioning mechanism 4 includes a cylinder The first clamping block 46 and the second clamping block 47 are driven to move toward each other, and the opposite sides of the first clamping block 46 and the second clamping block 47 cooperate to form a clamping groove 48 for clamping the headless pump. Furthermore, after the headless pump is sent into the feeding port by the feed rail 22, the mutual clamping of the first clamping block 46 and the second clamping block 47 can be used to control the headl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com