Numerical controller for controlling collision position of cutter tip of tool and workpiece

A numerical control device and cutting tool technology, applied in program control, manufacturing tools, digital control, etc., can solve problems such as inability to eliminate blade chipping, and achieve the effect of suppressing chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments and drawings of the present invention will be described below.

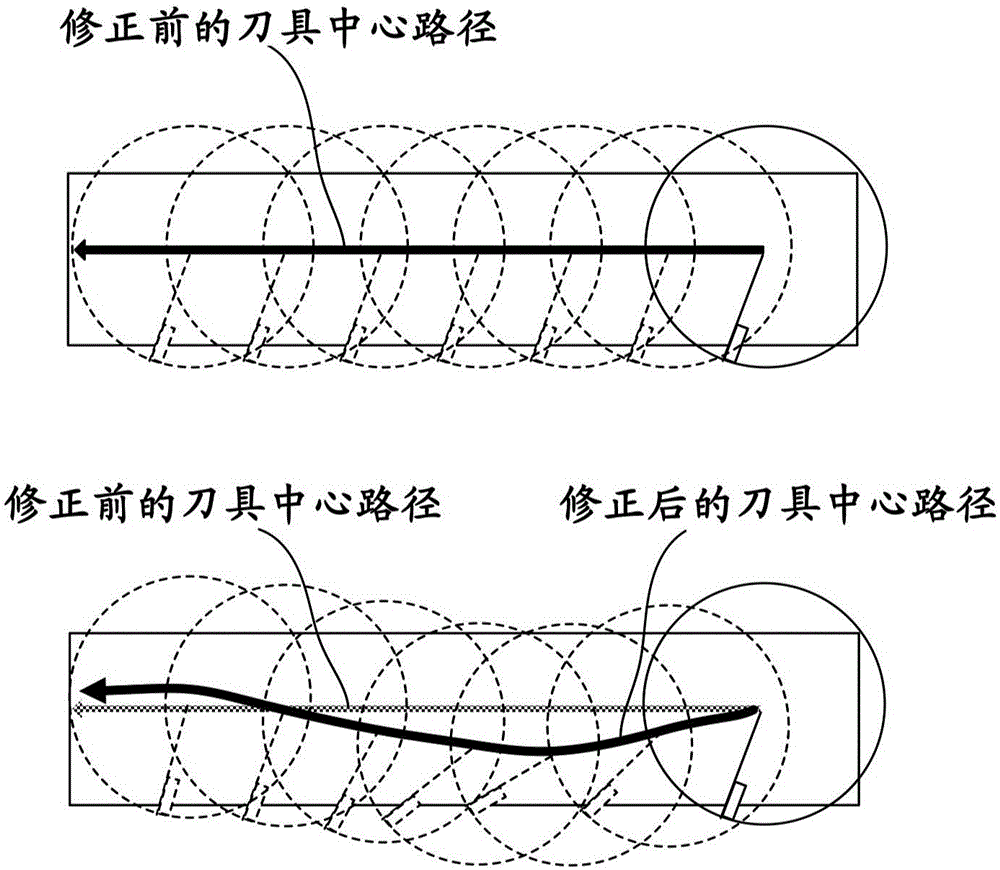

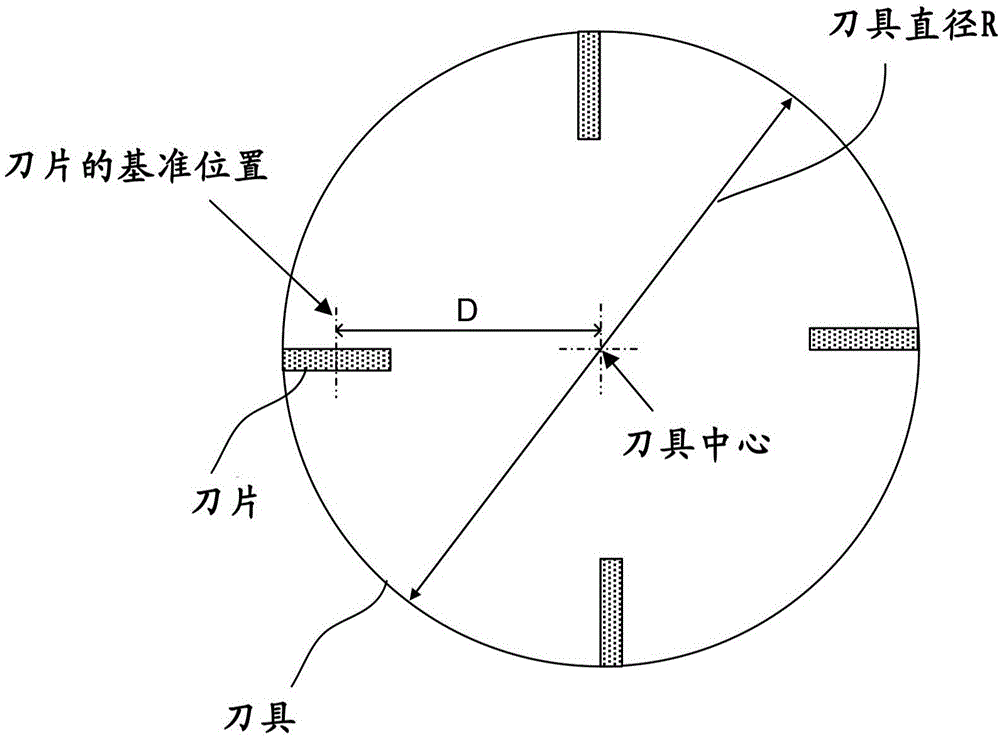

[0034] In the present embodiment, in end mill machining using a tool with inserts, as figure 1 As shown, the tool position is corrected in the vertical direction from the (programmed) tool center path determined by the program, so that the collision position between the blade and the workpiece is not concentrated on a specific position of the blade.

[0035] The present embodiment provides a numerical control device that generates a relationship between the insert and the workpiece based on the information on the tool having the insert used in end mill machining, the shape information of the workpiece, and the information on the use range of the insert. The collision location is not centered on the toolpath at a specific location of the insert.

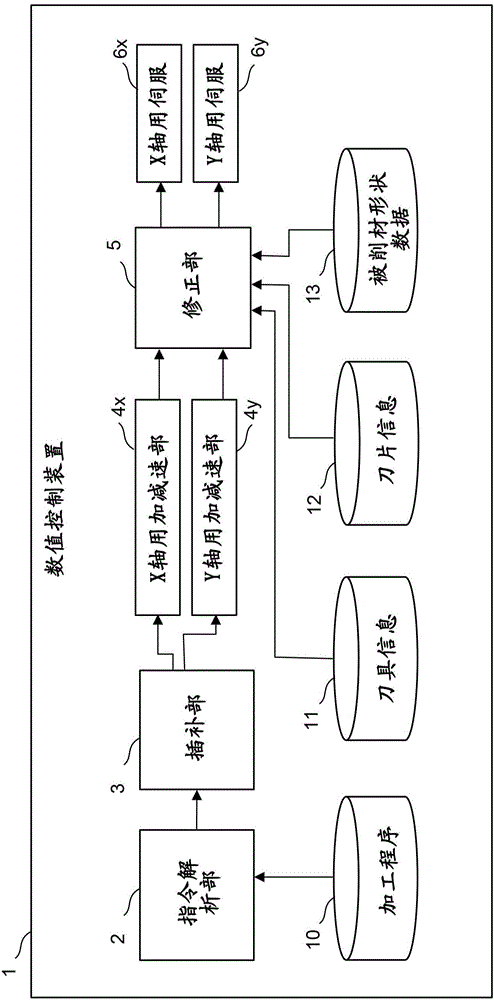

[0036] figure 2 It is a schematic configuration diagram of the numerical controller of this embodiment. The numerical controller 1 of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com