Manufacturing method of optical film

A manufacturing method and optical film technology, applied in optics, optical components, instruments, etc., can solve problems such as poor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0161] These compounds may be added together with the cellulose ester or the solvent during preparation of the cellulose ester solution, or may be added during or after the preparation of the solution.

[0162] (delay modifier)

[0163] As the compound added for retardation adjustment, an aromatic compound having two or more aromatic rings described in European Patent No. 911,656A2 can be used.

[0164] In addition, two or more aromatic compounds may be used in combination. Among the aromatic rings of the aromatic compound, it is particularly preferable to contain an aromatic heterocyclic ring in addition to the aromatic hydrocarbon ring. An aromatic heterocycle is usually an unsaturated heterocycle. Among them, a 1,3,5-triazine ring is particularly preferable.

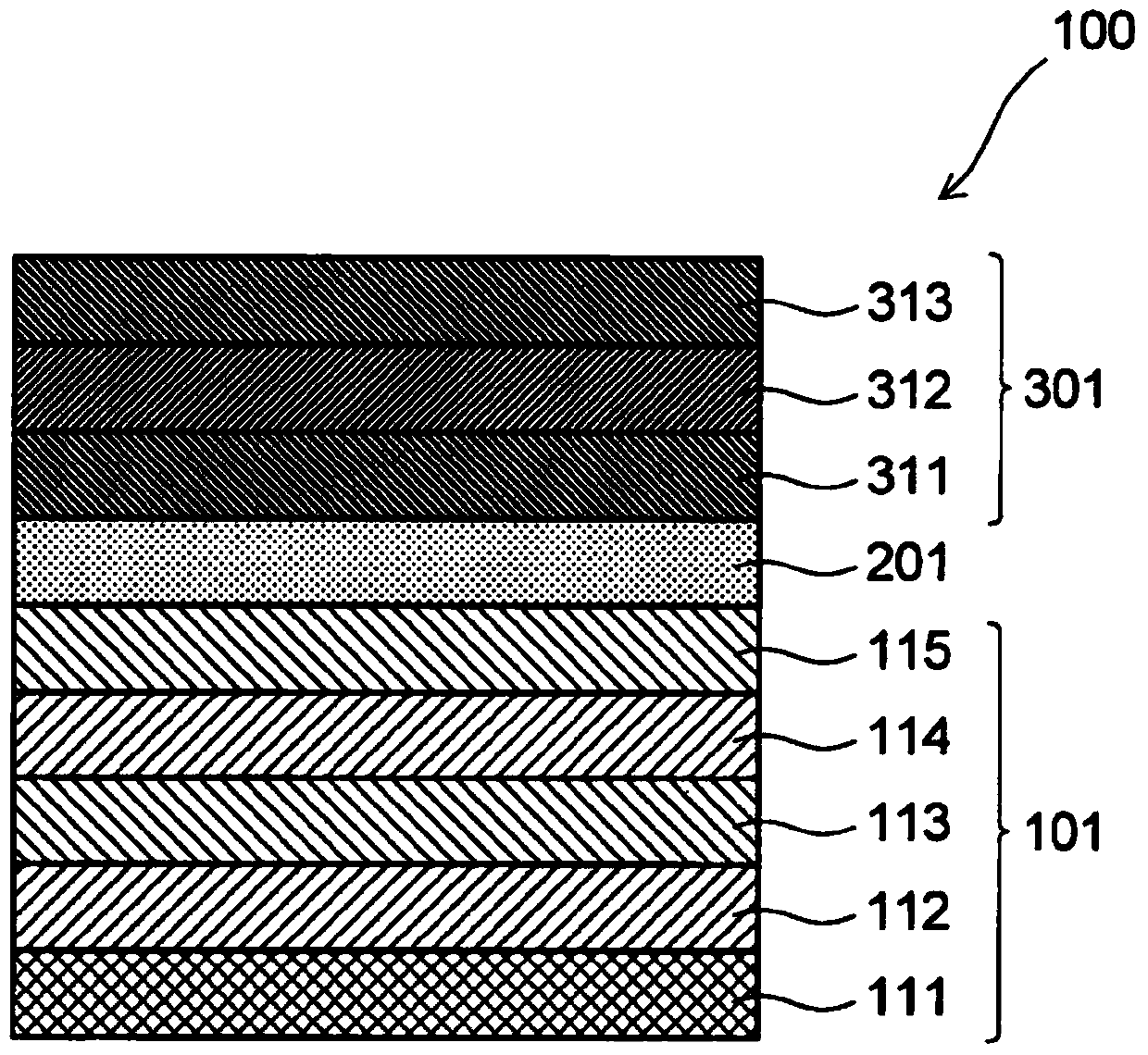

[0166] The cellulose ester film in this embodiment preferably contains cellulose ester and a vinyl group having a substituent selected from a carboxyl group, a hydroxyl group, an ami...

Embodiment 1

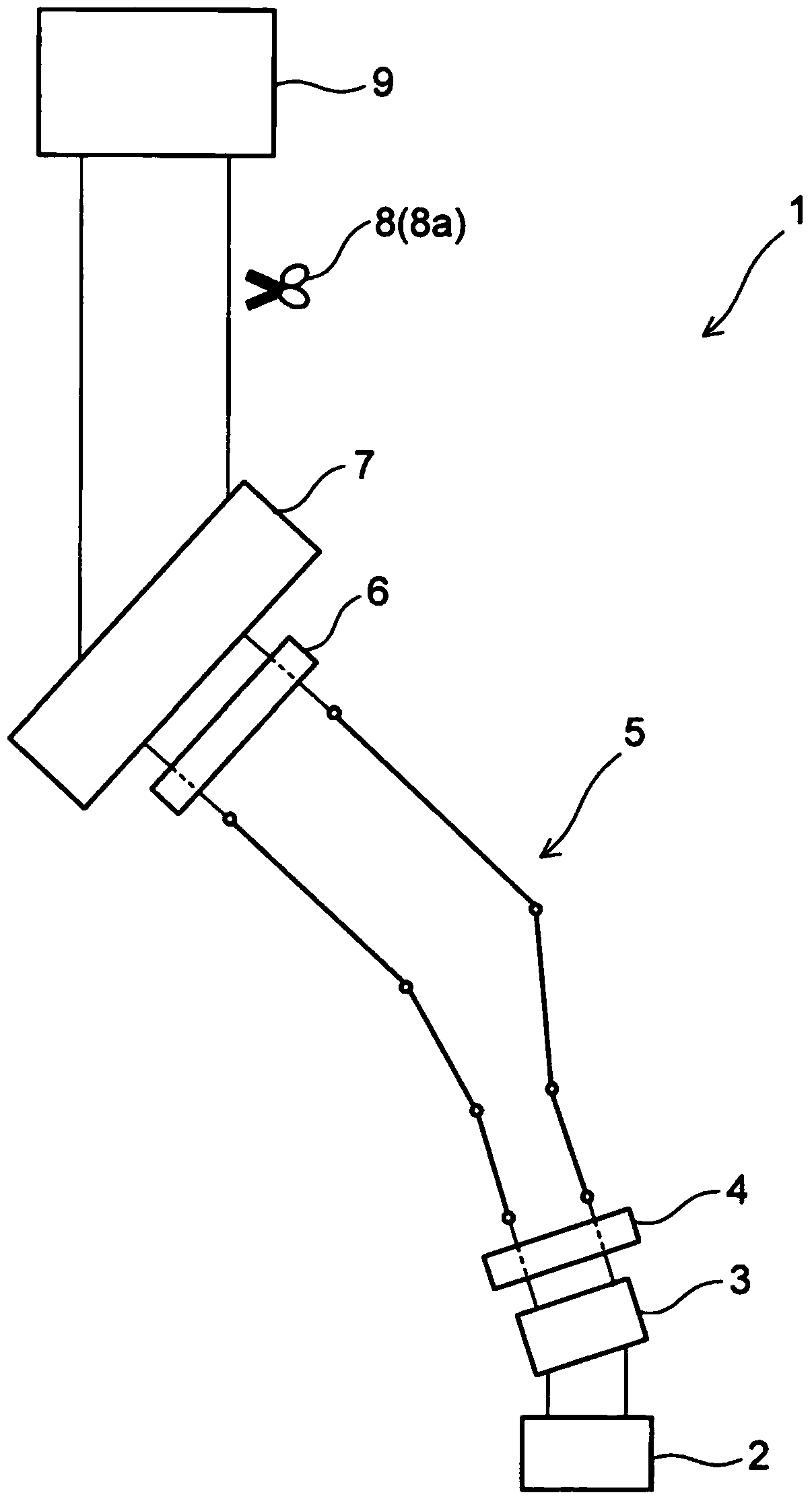

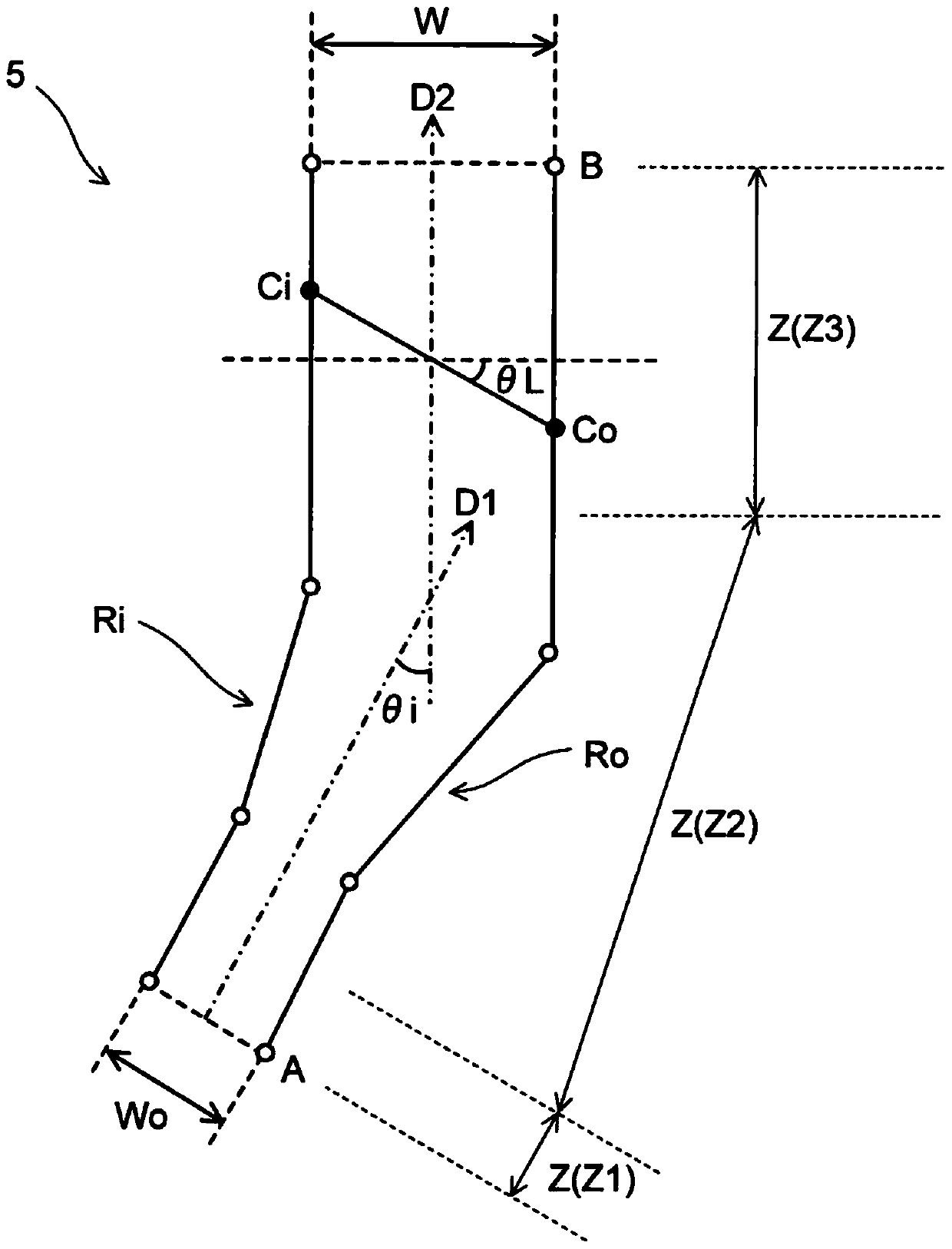

[0376] The elongated oblique orientation film A' made of the COP film is wound up by the film winding part 9 Figure 4The shown film cutting device 8 (cutting member 8a) moves in the width direction and cuts to a predetermined length. At this time, the elongated obliquely oriented film A' was cut with a tension of 5 N per unit length in the width direction applied along the longitudinal direction to the elongated obliquely oriented film A'. In addition, in the cutting of the elongated oblique alignment film A', the tension applied in the longitudinal direction was set to be constant (5 N / m), and the blade of the cutting member 8a moved earlier than the lower surface of the elongated oblique alignment film A'. into the upper surface.

[0377] (Manufacture of circular polarizer)

[0378] Next, a polyethylene film with a thickness of 120 μm was uniaxially stretched (at a temperature of 110° C. and a stretching ratio of 5 times), immersed in an aqueous solution composed of 0.075...

Embodiment 2

[0380] In Example 2, when the elongated oblique alignment film A' was cut along the width direction, the tension applied to the length direction was set to be 30 N per unit length in the width direction, and the tension was set to be constant during cutting (30 N / m). Other than that, it is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com