Cutting tools made of cubic boron nitride based sintered materials

A cubic crystal boron nitride, boron nitride-based technology, applied in the manufacture of tools, workpieces, drilling accessories, etc., can solve the problem of insufficient chipping resistance and chipping resistance, a decrease in the proportion of cBN particles, and a decrease in tool hardness etc. to achieve excellent cutting performance, uniform tool properties, and reduced tensile residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

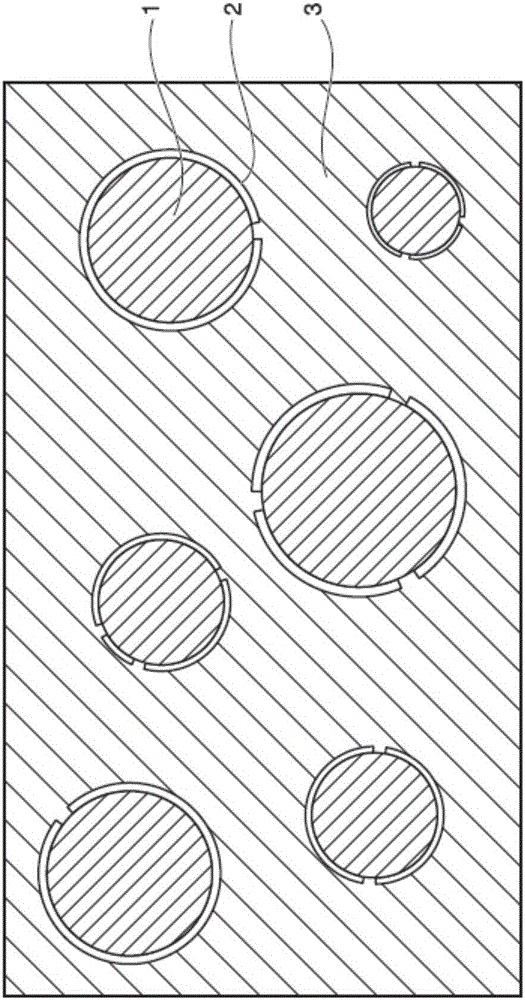

[0116] Al 2 o 3 Fabrication of membrane-coated cBN particles:

[0117] (a) Using cBN particles with an average particle size of 0.5 to 8 μm as the substrate, the surface of the particles is coated with uniform and thin Al by the ALD (Atomic Layer Deposition) method 2 o 3 membrane.

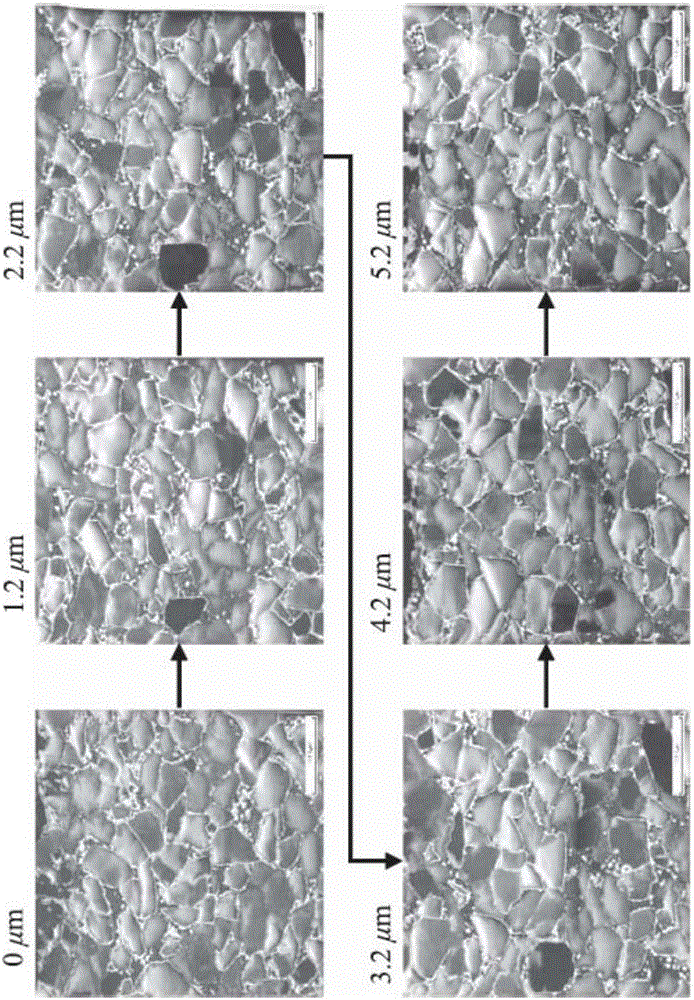

[0118] More specifically, for example, cBN particles having an average particle diameter of 3 μm are charged in the furnace, and the temperature in the furnace is raised to about 350° C. Second, using Al(CH 3 ) 3 and H 2 O gas is used as the film-forming gas, and Ar gas is used as the purge gas to carry out (i) Ar+Al(CH 3 ) 3 Gas inflow process, (ii) Ar gas purge process, (iii) Ar+H 2 O gas inflow process, (iv) Ar gas purge process. The steps (i) to (iv) are regarded as one cycle, and this cycle is repeated according to the desired film thickness. By forming a film for 1 to 12 hours, the surface of cBN particles is uniformly coated with Al having a desired film thickness. 2 o 3 membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com