A compact high heat dissipation busway

A technology with high heat dissipation and busbar trunking, applied in the field of busbar trunking, can solve the problems of increasing the difficulty and cost of construction, large busbar trunking, and increased installation space, and achieves low production and processing costs, small size, and improved heat dissipation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

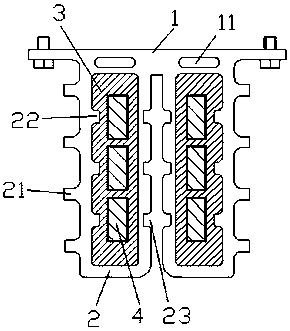

[0014] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0015] A compact high heat dissipation busway, comprising: a fixed floor 1 and two symmetrically arranged closed wire frames 2, the two closed wire frames 2 are arranged under the fixed floor 1 at intervals, and a gap is left between the two closed wire frames 2 There are gaps, and the performance of ventilation and heat dissipation is good.

[0016] The outer surface of the closed wire frame 2 is respectively provided with outwardly protruding cooling fins 21, and the inner surface of the closed wire frame 2 is respectively provided with inwardly sunken ventilation grooves 23. The closed wire frame 2 is provided with an inner hole, and the inner holes are respectively filled with plastic filling strips 3, and several conductive bars 4 are arranged at intervals among the plastic filling strips 3. The heat dissipation performance of the closed wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com