Zipper with t-shaped elements

A chain element and ribbed technology, which is applied in the field of zippers, can solve the problems of small design space of chain elements, reduce the aesthetics of zippers, affect the softness of zippers, etc., achieve low manufacturing costs, facilitate personalized design, and increase creativity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

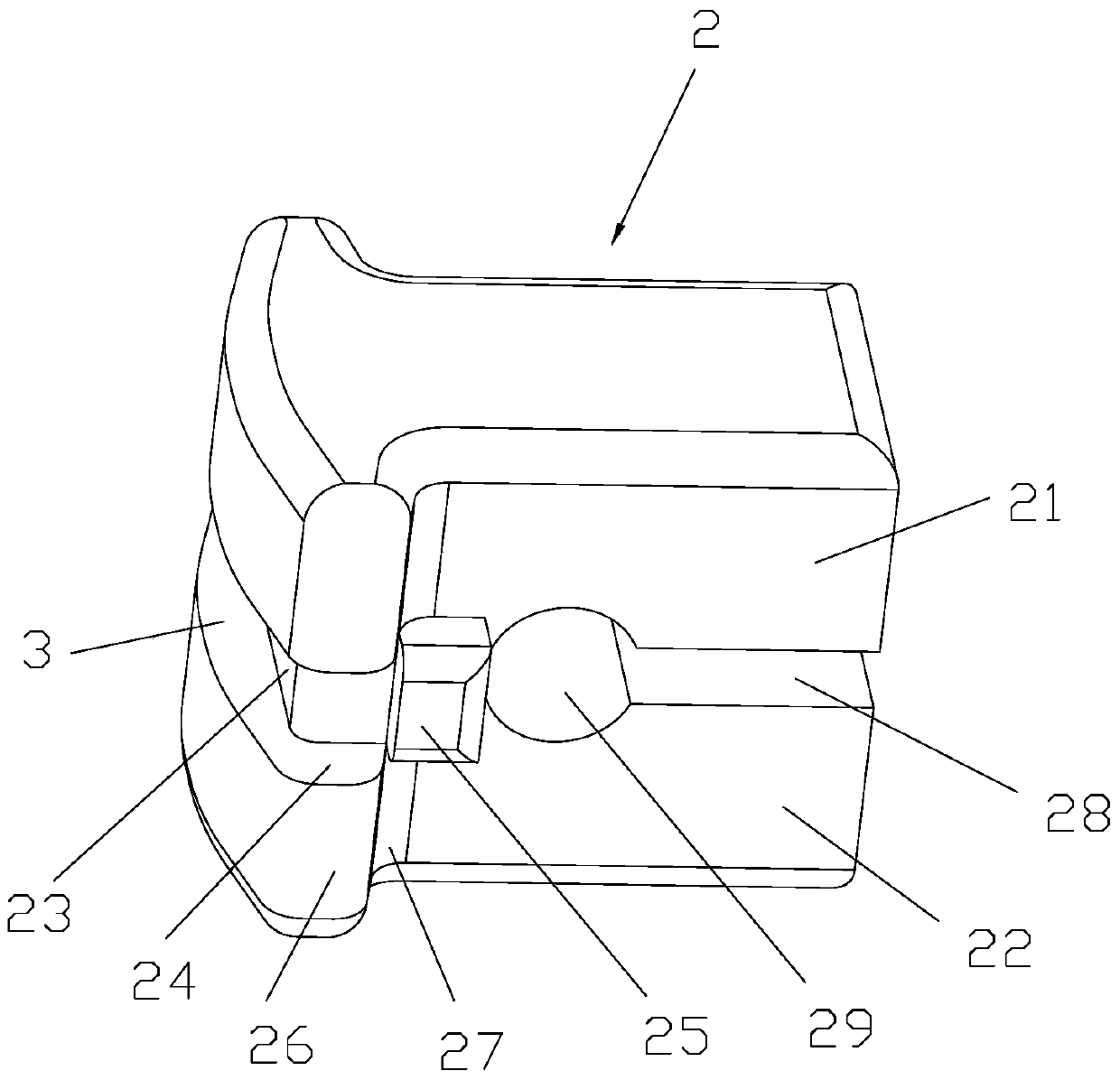

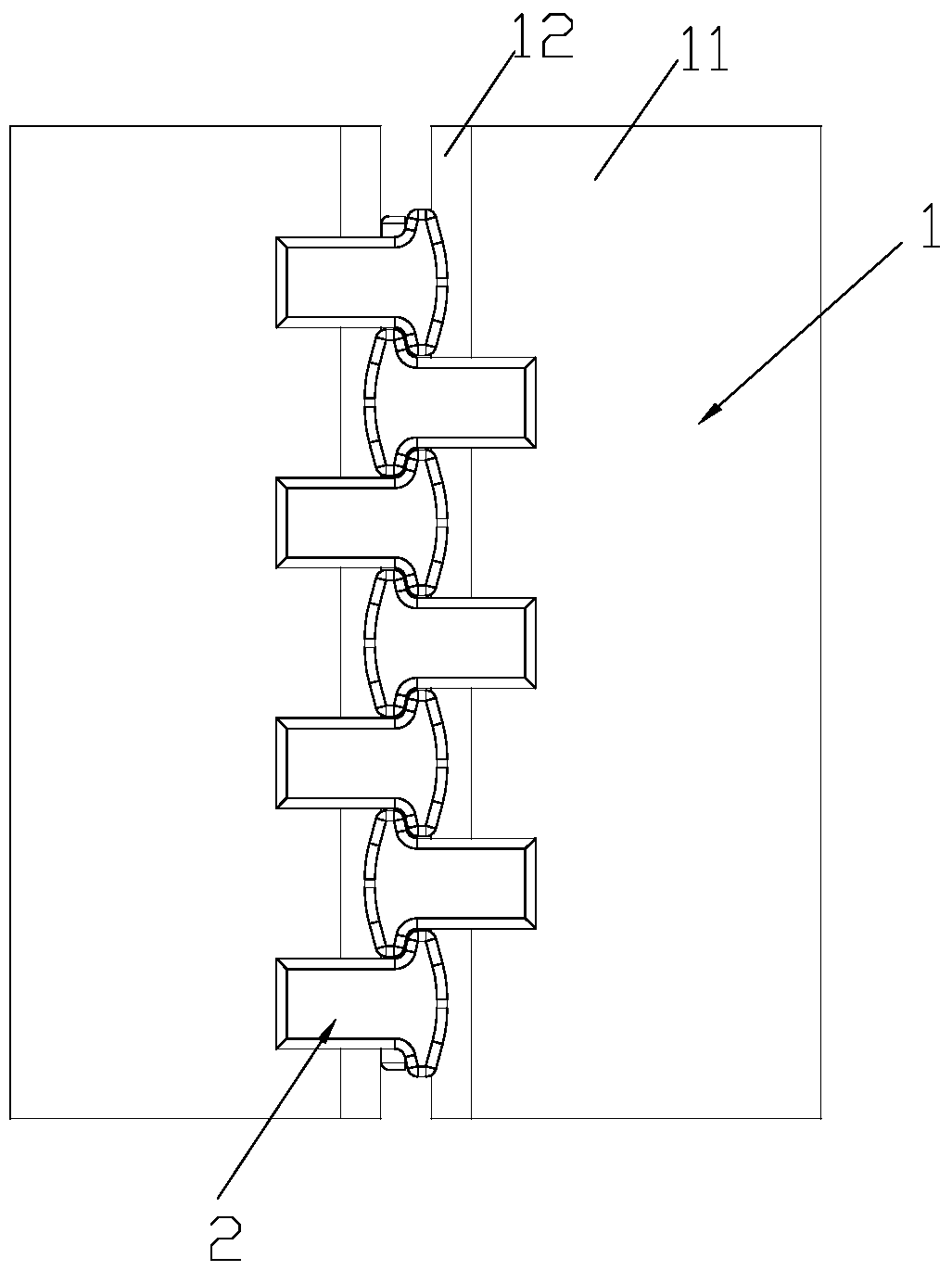

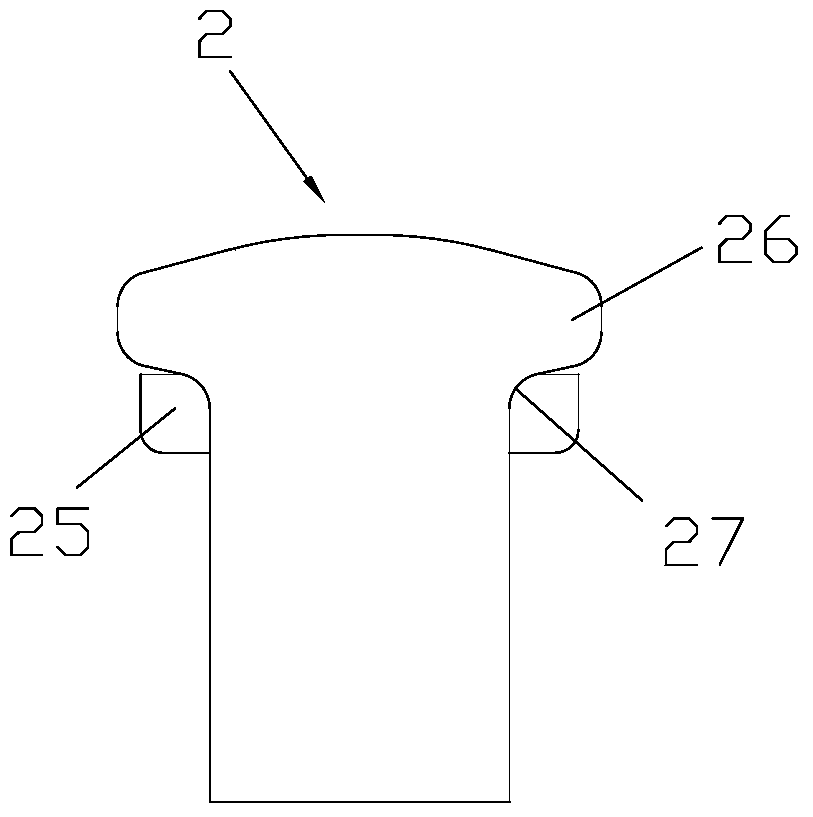

[0015] like Figure 1 to Figure 3 As shown, a zipper with T-shaped fastener elements includes a cloth tape 1 and fastener elements 2, and the fastener elements 2 are equidistantly assembled on the cloth tape 1, and the fastener elements 2 are integrally formed, and the fastener elements 2 includes the same first card body 21 and second card body 22, the first and second card bodies 21, 22 are T-shaped, adopt T-shaped design, the size of the tooth body can be designed casually, as long as the strength is satisfied, then Compared with the meshing method of the original zipper, the meshing part of the chain element 2 is larger, so that the chain element 2 is connected more tightly and firmly, and will not be separated at will. The zipper can be easily bent and folded at will, and has good flexibility. It is used in daily life. more convenient.

[0016] A connection block 23 is arranged between the first card body 21 and the second card body 22, and the connection block 23 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com