Classification unified harvesting-type cotton picker picking head and cotton picker

A technology of cotton pickers and locomotives, which is applied to pickers, harvesters, agricultural machinery and tools, etc. It can solve problems such as waste, poor adaptability of cotton pickers, and large mechanical wear, so as to ensure the quality of cotton and increase the income of cotton farmers , Adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

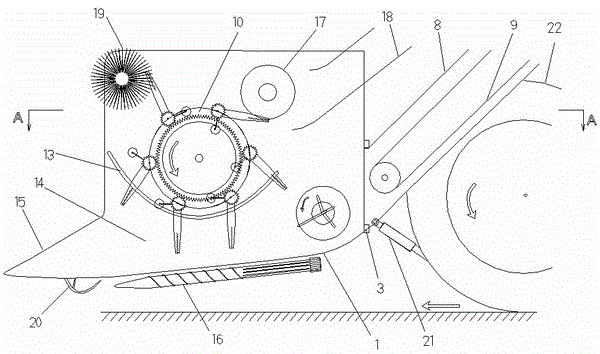

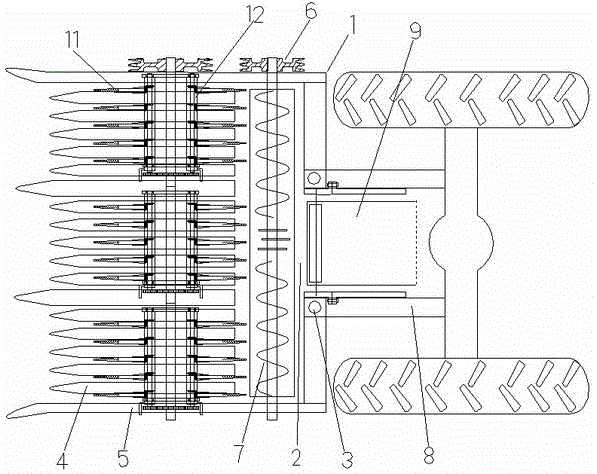

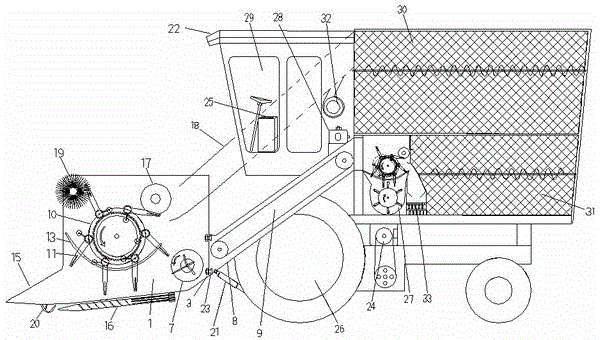

[0020] figure 1 , figure 2 Among them, the grading unified collection type cotton picker is suspended and fixed in front of 22 cotton pickers when picking the head. The main frame of the decapitation is an approximate shovel head-shaped auger tank 1, on the rear side of the auger tank 1, that is, on the side close to the front of the car, there is a discharge port 2 and a docking device 3, the said The front side of the auger trough 1 extends forward, and the extension surface is comb-shaped, and the cotton rod can pass between the 4 comb teeth. If the shortest distance between the adjacent comb teeth 4 is too small, it is not conducive to the cotton rod in and out. , there may be too many broken rods entering the auger trough, on the contrary, if the distance between the 4 comb teeth is too large, some cotton bolls and cotton flowers may be pulled out of the auger trough 1, so the closest comb between adjacent comb teeth The distance is fixed between 12mm and 25mm. There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com