A control system for scale breaking unit before pickling of strip steel

A unit control and motor control technology, which is applied in rolling mill control devices, manufacturing tools, metal rolling, etc., can solve problems such as plastic deformation of steel plates, affecting product use, and unfavorable handling, so as to save hydrochloric acid, increase production line speed, and improve crushing. The effect of the scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0017] The invention provides a control system of a scale breaking unit before pickling of strip steel.

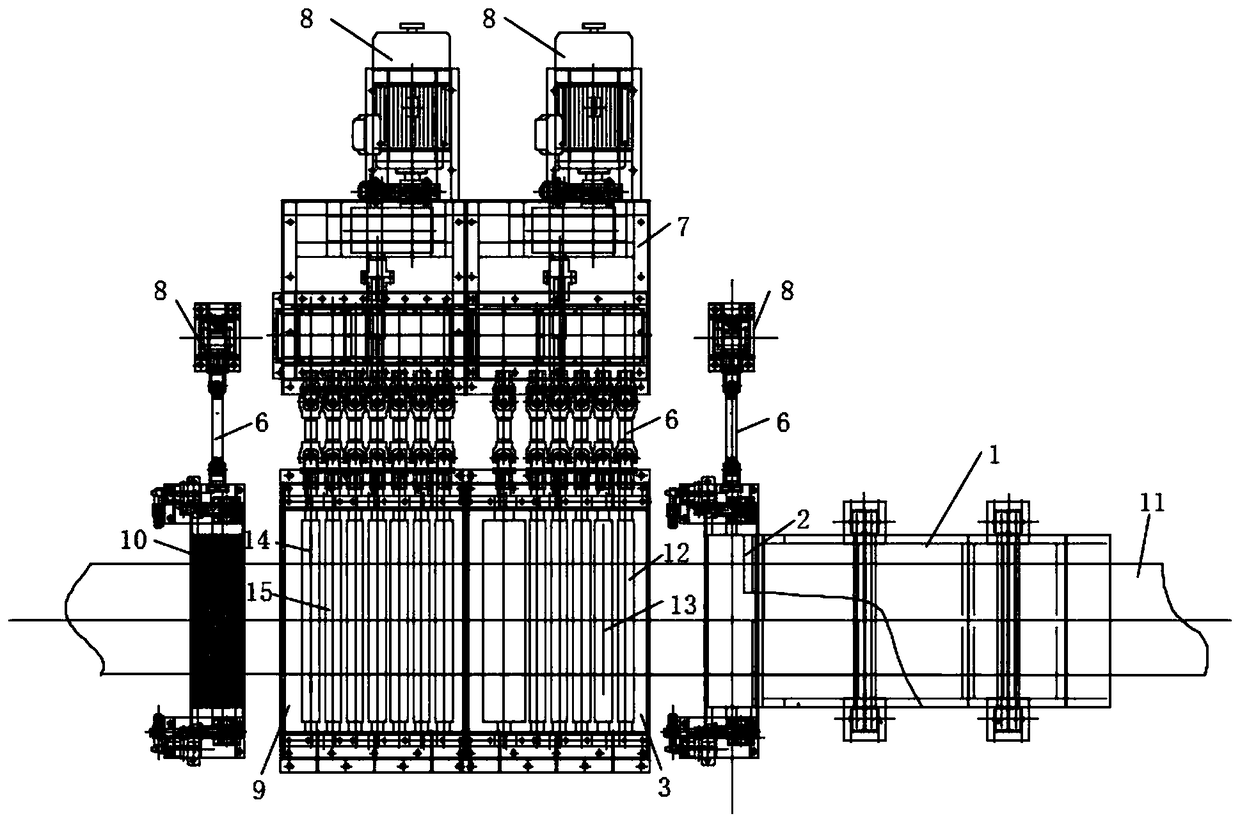

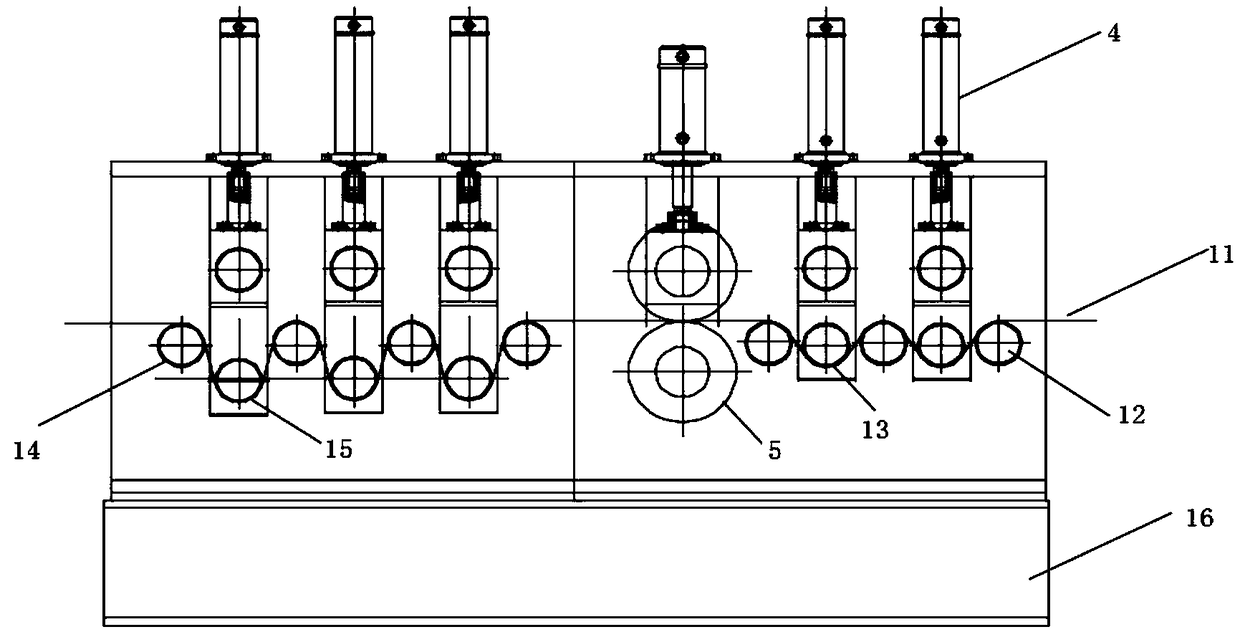

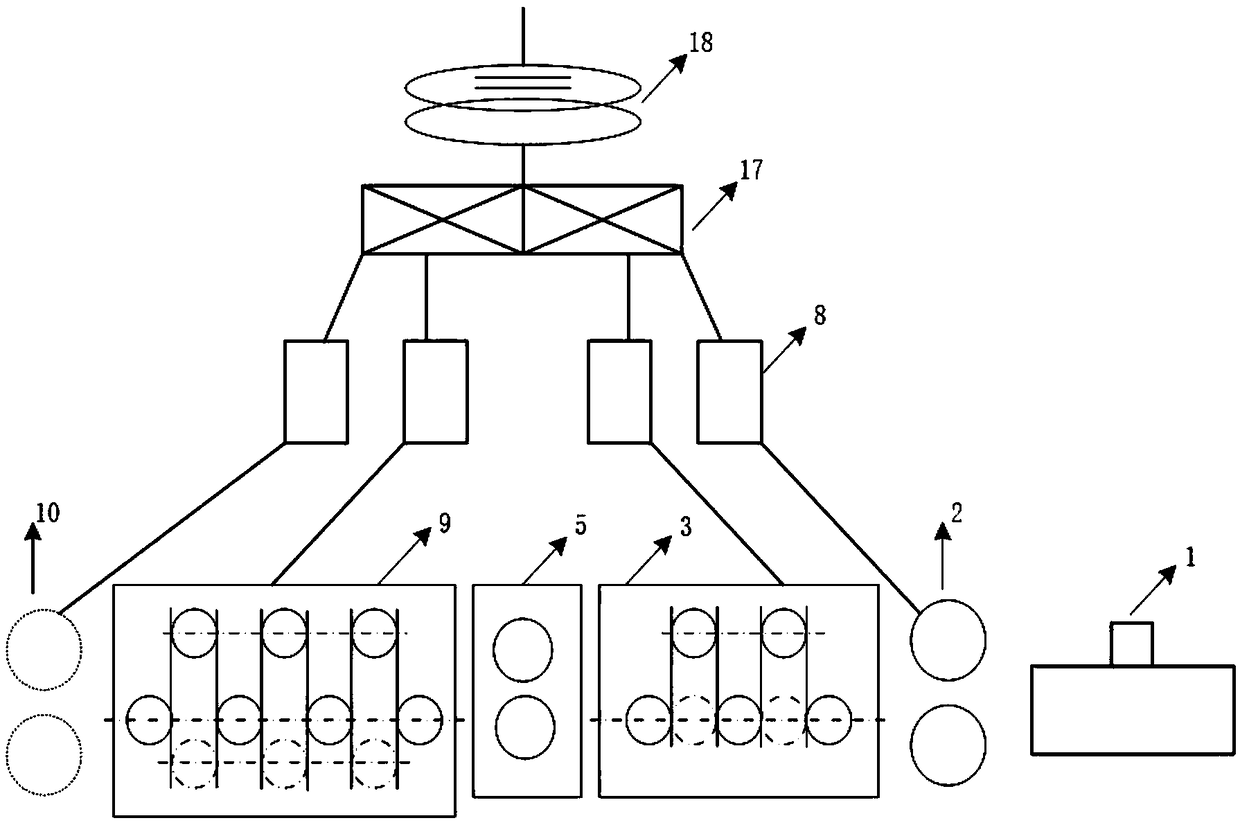

[0018] like figure 1 and figure 2 As shown, in this control system, the entrance welding platform 1 is located at the end of the entire control system, the entrance pinch roller 2 is arranged behind the entrance welding platform 1, and the entrance unit 3 is arranged behind the entrance pinch roller 2, and the entrance pinch roller 2 is composed of The driving motor 8 is driven by the transmission shaft 6, the entrance pinch roller 2 receives the strip 11 at the exit of the entrance welding platform 1, and drives the strip 11 to move, and sends the strip 11 to the entrance unit 3 for preliminary scale breaking, and the entrance unit 3 The outlet u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com