A Combined Cold Rolling Stretch Bending Straightening Machine

A tensile, bending, straightening and combined technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of poor strip breaking effect, reduced enterprise economic benefits, inconsistent scale breaking effect, etc. Improve the flatness and quality of the board surface, reduce the risk of over-stretching of the weld seam, and correct the effect of flatness defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0019] The invention provides a combined cold rolling stretch bending straightening machine.

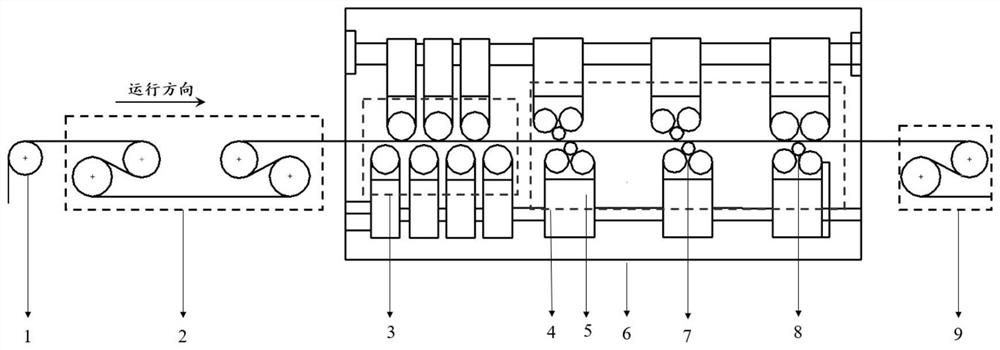

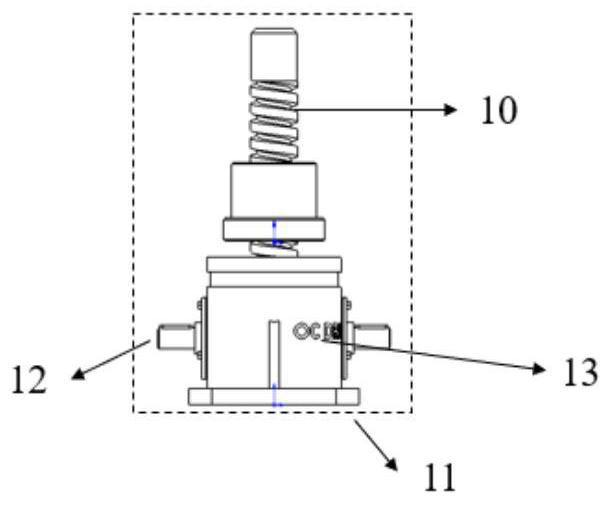

[0020] like figure 1 As shown, the straightening machine includes steering roll 1, entrance tension roll set 2, multi-roll straightening system 3, stretch straightening roll set 4, roll box 5, frame 6, bending roll set 7, straightening roll set 8. Exit tension roller group 9 and elevator, steering roller 1, entrance tension roller group 2, multi-roll straightening system 3, stretch straightening roller system 4, bending roller group 7, straightening roller group 8 and exit tensioning The roll group 9 is arranged in sequence along the strip conveying direction, the multi-roll straightening system 3, the stretching straightening roll system 4, the bending roll g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com