Anchor plate repair machine and repair method thereof

A technology for repairing machines and anchor plates, which is applied in the field of anchor plates for underground support in coal mines. It can solve the problems of inconvenient operation, time-consuming and labor-intensive work, and low efficiency, and achieve the effects of simple structure, improved correction efficiency, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

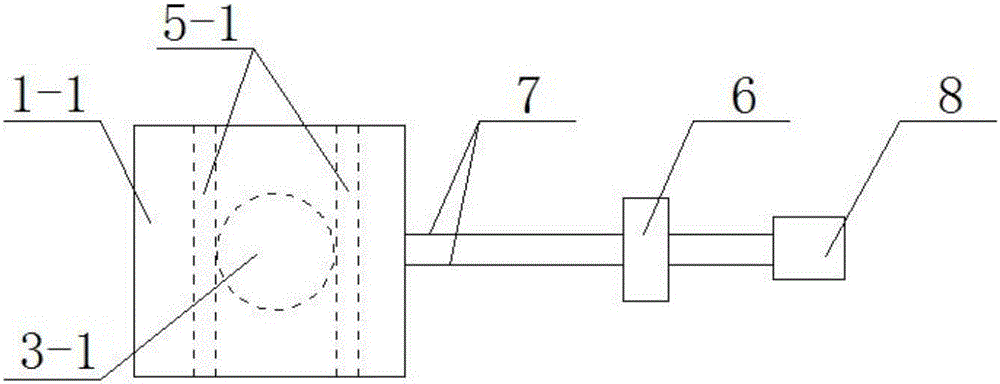

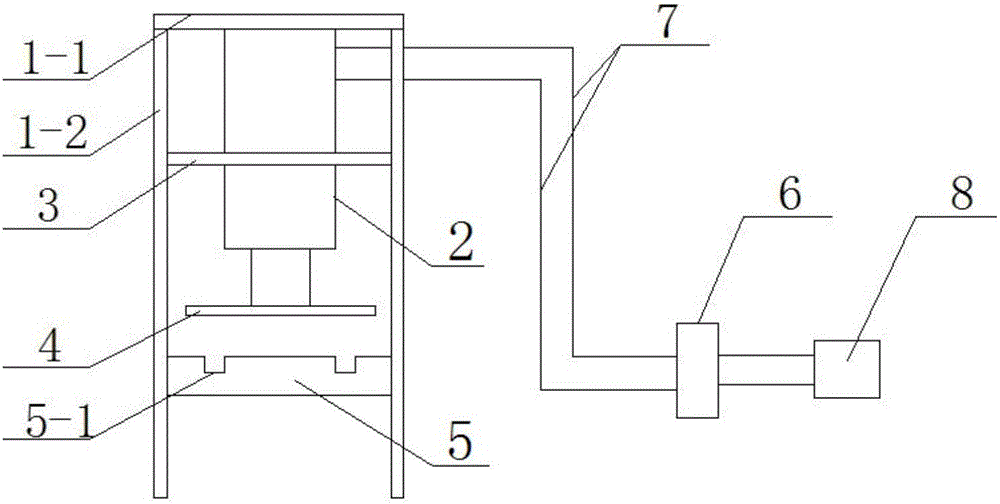

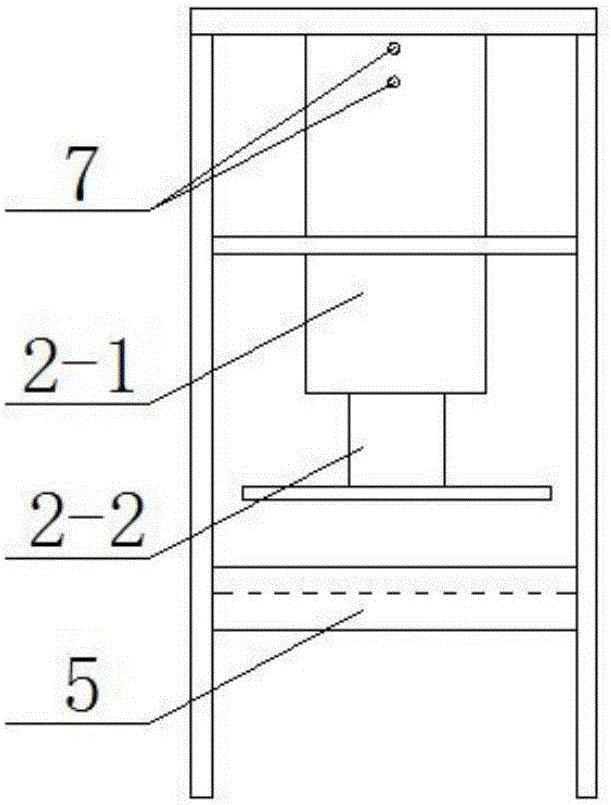

[0024] Example: such as Figure 1-Figure 5 As shown, an anchor plate repair machine includes a frame 1, a hydraulic cylinder 2, a pressure plate 4 and a pressure bearing plate 5, the vertical direction of the middle part of the frame 1 is a cavity structure, and the cylinder body 2-1 tail end of the hydraulic cylinder 2 Fixedly connected to the top of the frame 1 by welding, the end of the piston rod 2-2 of the hydraulic cylinder 2 is fixedly connected to the pressure plate 4 by welding, and a pressure plate 5 is installed at a distance below the pressure plate 4, and the pressure plate 5 is installed on the machine. On the frame 1, the effective distance for the pressure plate 4 to move downward exceeds the upper surface of the pressure bearing plate 5.

[0025] Above-mentioned pressing plate 4 is iron plate, becomes square, and thickness is 8mm, and size is 280mm*280mm.

[0026] The above-mentioned bearing plate 5 is an iron plate, which is square, with a thickness of 25mm ...

Embodiment 2

[0033] Embodiment 2: a kind of repairing method of anchor plate repairing machine, this method comprises the following steps:

[0034] (1) Connect the hydraulic cylinder to the pump station and the switch on the console, and set the maximum pressure of the hydraulic cylinder to;

[0035] (2) Place the anchor plate on the center of the pressure bearing plate, and place the two convex strips of the anchor plate in the symmetrical grooves on the pressure bearing plate;

[0036] (3) Control the switch button on the console to push out the piston rod of the hydraulic cylinder and press the pressure plate to the anchor plate;

[0037] (4) When the pressure plate is pressed to the designated position, control the switch button on the console to retract the piston rod of the hydraulic cylinder;

[0038] (5) Repeat steps (3)-(4) several times to complete the correction of the anchor plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com