Structure-adjustable self-locking screw rod

A self-locking screw and adjustable technology, which is applied in the direction of screws, nuts, bolts, etc., can solve the problems that the angle of installation cannot be adjusted according to actual needs, the joint surface of the screw and nut cannot be fixed by self-locking, and the screw structure is fixed in a single way. The assembly structure is firm and stable, improving the safety and firmness of assembly, and improving the thread assembly area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

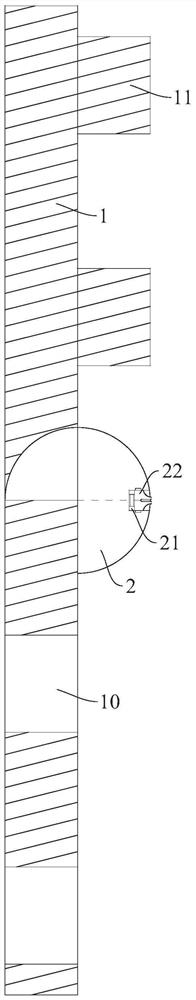

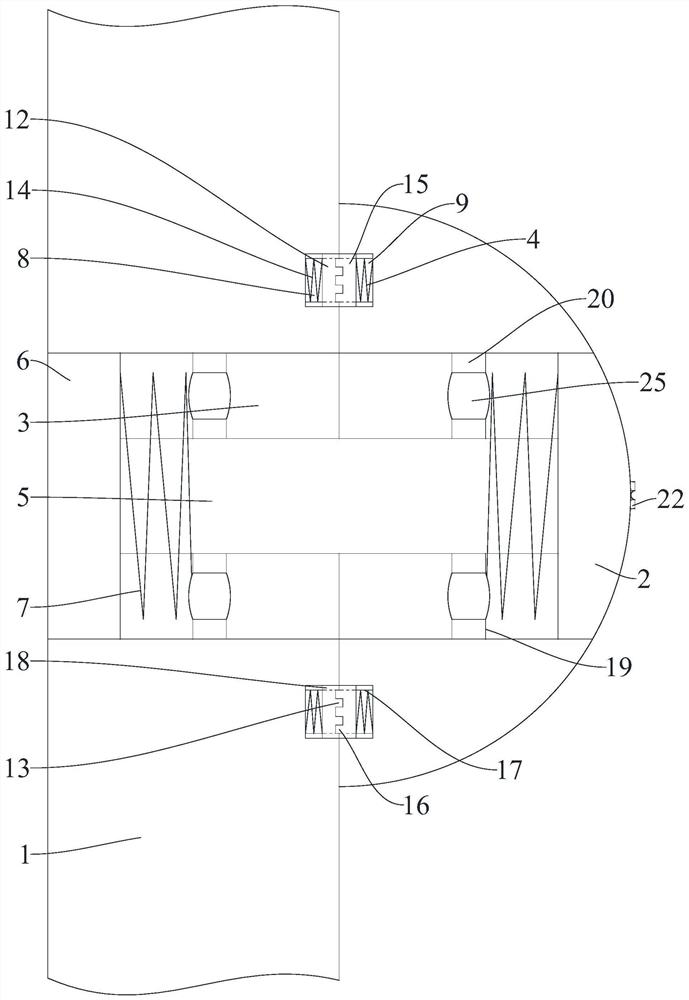

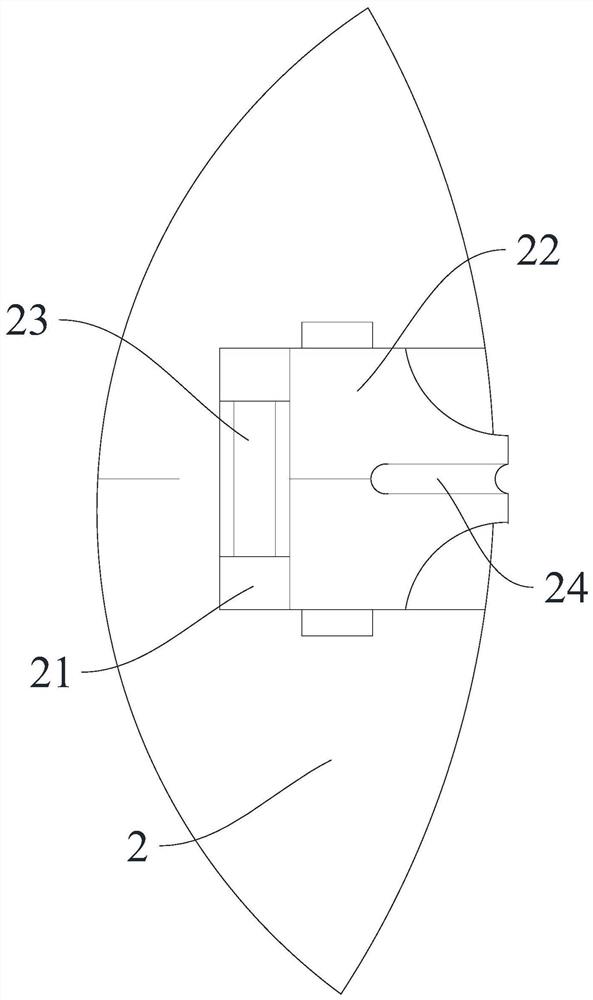

[0024] EXAMPLES: The first outer thread rod 1 is fitted with the second outer threaded rod 2 by an internal fitting shaft 5, and when the first locking block 13 is engaged with the second locking block 16, this can be threaded The angle between the rod 1 and the second outer thread 2 is locked and fixed.

[0025] The first outer threaded rod 1 and the second outer threaded rod 2 are rotated in reverse, so that the outer screw block 11 is inserted into the insertion side to form an integral thread rod, which can be convenient to accommodate each other, while also passing The outer screw cloth 13 lifts the firmness of the thread assembly.

[0026] Further, in order to match the inner limit and lock, the first elastic lock ring includes a first telescopic ring 12 inserted inside the first shrink groove 8, and is fixed to the first lock stop on the outer side of the first telescopic ring 12. The block 13 and the first extrusion spring 14 mounted on the inner side of the first telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com