A sieve cylinder chain bounce vibrating device

A vibrating device and chain bomb technology, applied in the field of drum vibrating screen, can solve the problems of radiation effect that cannot form vibration, loss of power source energy, and inability to clean materials, etc., to achieve convenient and fast loading and unloading maintenance, prolong practical life, and vibration effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

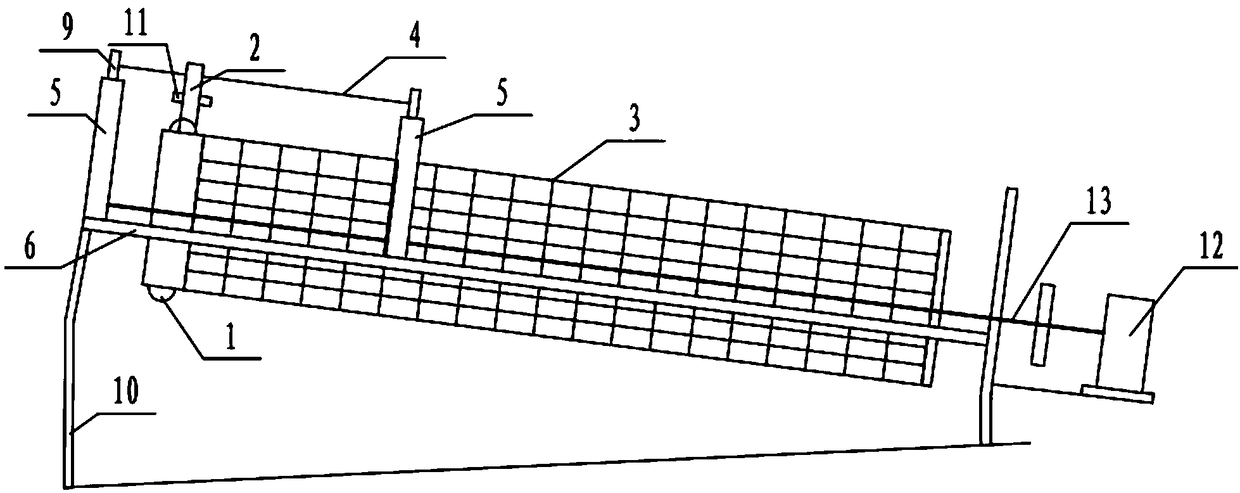

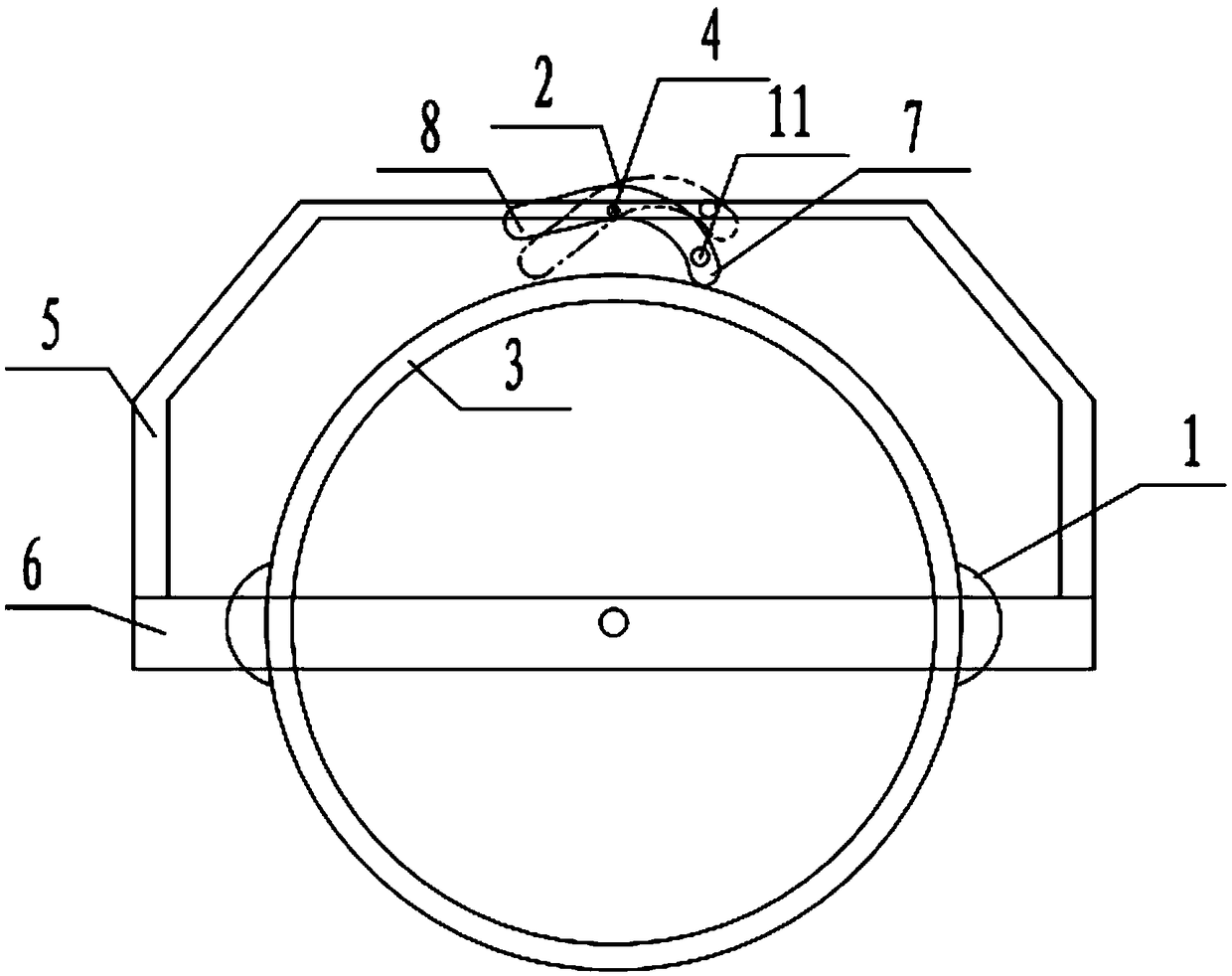

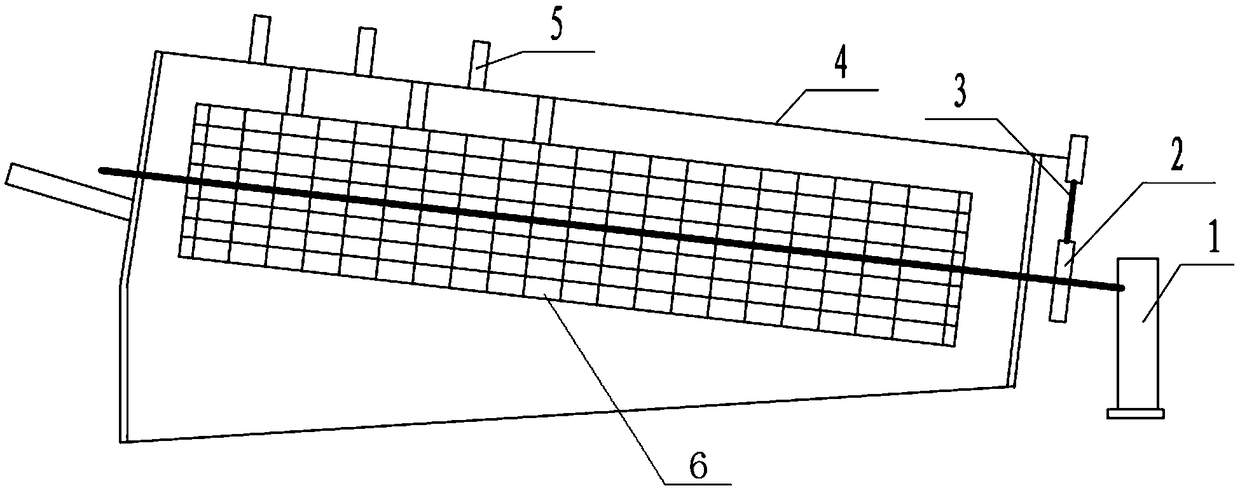

[0018] Example: such as Figure 1-Figure 2 As shown, a sieve cylinder chain bounce vibration device includes a semicircular bump 1 and a crescent-shaped adjustable drop hammer 2. The bump 1 is fixedly connected to the outer cylindrical surface of the sieve cylinder 3 by welding, and its arc The shape direction is the same as the circumferential direction of the screen drum 3, the middle part of the adjustable drop hammer 2 is fixedly connected to the rotating shaft 4 above the screen drum 3 and bent downward, and the two ends of the rotating shaft 4 are respectively connected to the two brackets 5 through two bearing boxes 9, The two bearing boxes 9 are fixedly connected to the bracket 5 by screws, and the axis of the rotating shaft 4 is kept parallel to the axis of the screen drum. The two brackets 5 are both inverted U-shaped structures, and their two lower ends are fixedly connected to the horizontal sides of the screen drum 3 by screws respectively. On the main frame 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com