Fixing and machining device of before-car transmission shaft

A technology for processing devices and transmission shafts, applied in the field of transmission shafts, can solve problems such as transmission failure, assembly errors, and processing errors, and achieve the effects of reducing processing errors, prolonging service life, and reducing assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

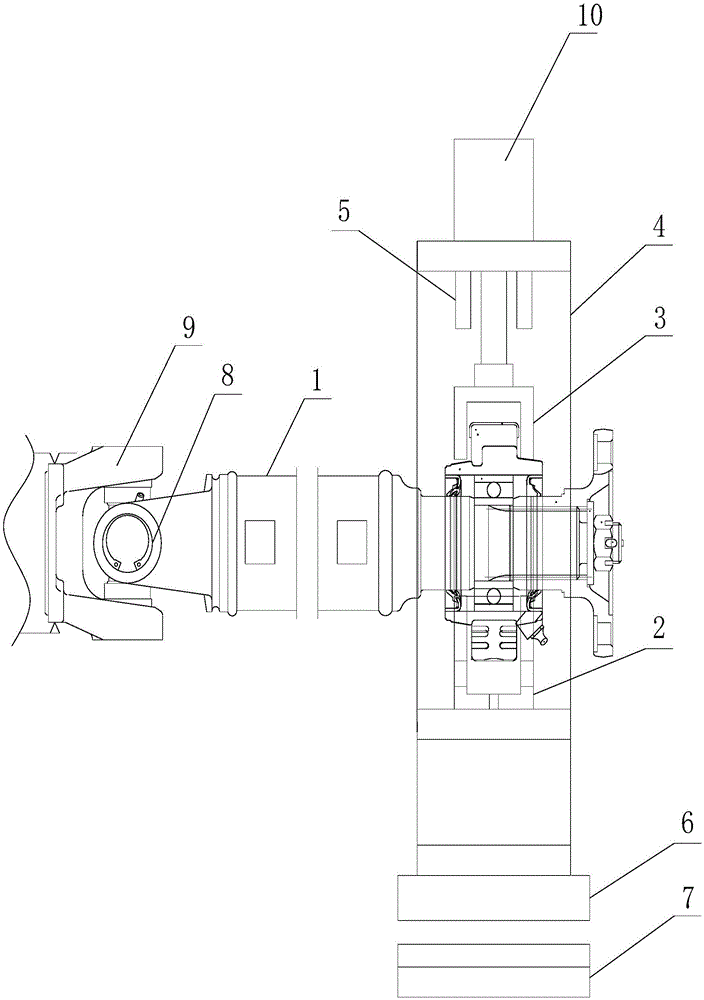

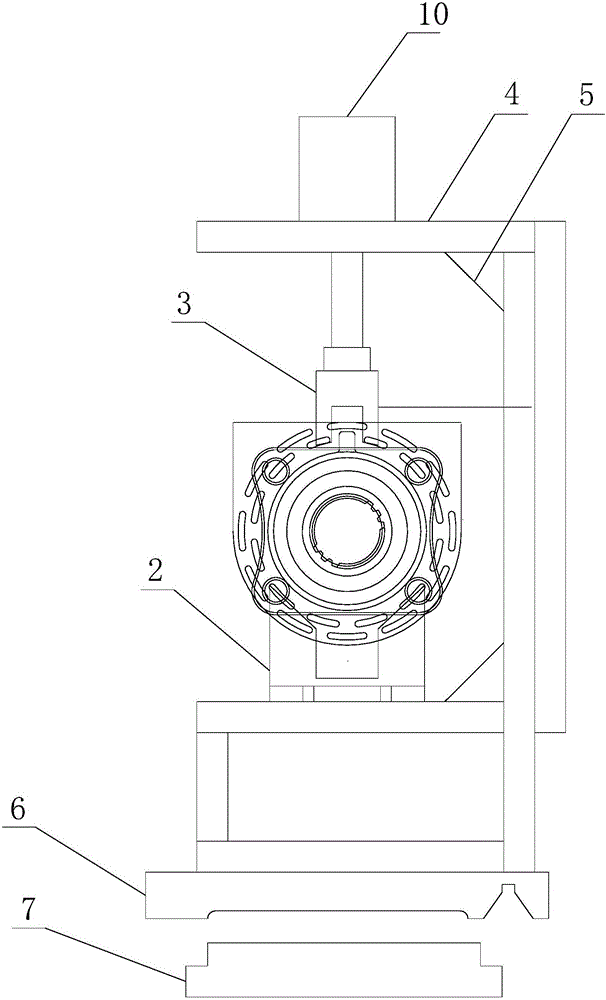

[0020] Such as figure 1 and figure 2 As shown, the fixed processing device of the front drive shaft includes a drive shaft 1, a bracket 4, at least one supporting fixture 2 and at least one pressing fixture 3; one end of the rotating shaft is connected with a flange fork 8, and the flange fork 8 is connected to the three parts of the machine tool. The claw chuck 9 is connected; the transmission shaft 1 is located between the support fixture 2 and the compression fixture 3; the compression fixture 3 is connected with a driving mechanism that controls its compression or release of the transmission shaft 1; the support fixture 2 and the compression fixture 3 are respectively Set on the inner bottom and inner top of the bracket 4; the clamping fixture 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com