Railway vehicle wheel set derusting machine

A technology for railway vehicles and derusting machines, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., and can solve the problem that manual labor is not suitable for wheel set derusting, cleaning work, hidden dangers caused by vehicle maintenance, and difficulty in derusting quality. Guarantee and other issues, to achieve the effect of compact structure, stable operation, and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

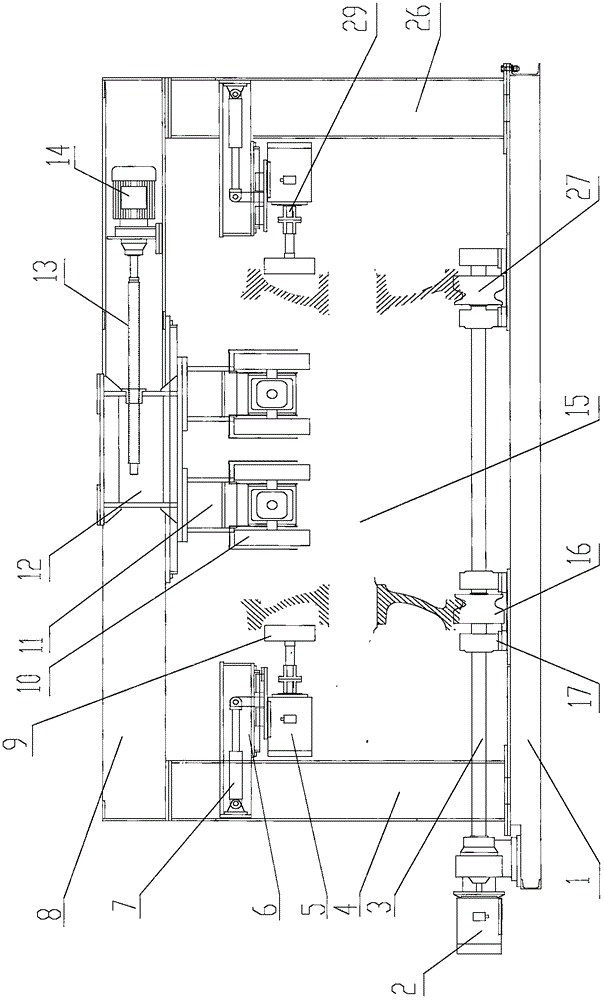

[0016] 1. Please refer to the attached figure 1 The main body (26) of the railway vehicle wheel pair derusting machine equipment is formed frame type structure by base (1), left and right two columns (4) and upper beam (8).

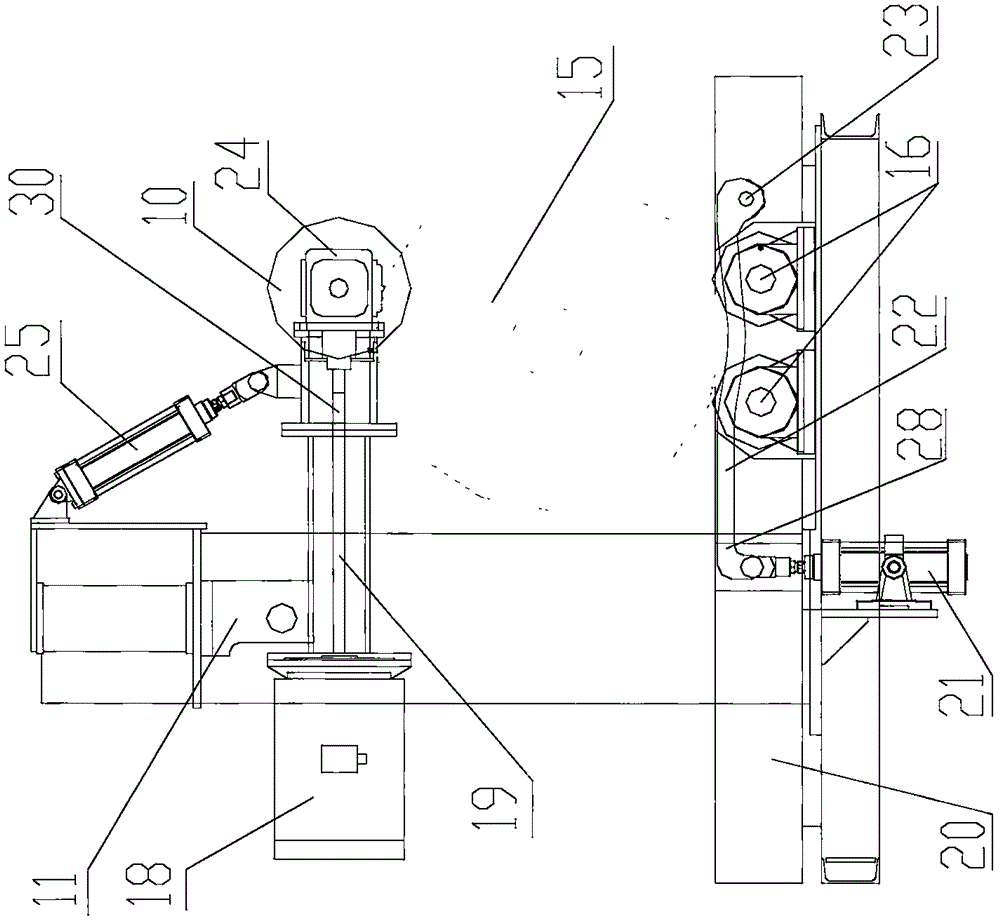

[0017] 2. Please refer to the attached figure 1 , 2 : runner mechanism (27) is made up of runner deceleration motor (2), connecting shaft 1 (3), roller (16) and bearing seat (17), and workpiece wheel pair (15) is on track (20), by left Enter the cleaning machine to the right, stop on the roller (16), the described wheel reduction motor (2) rotates, drive the roller (16) to rotate by the connecting shaft 1 (3), and the wheel pair (15) on the roller (16) ) rotates accordingly to cooperate with rust removal and cleaning.

[0018] 3. Please refer to the attached figure 1 : journal cleaning mechanism (29) is made up of support (6), horizontal cylinder (7), journal cleaning motor (5) and journal cleaning wire wheel (9) respectively equipped with on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com