Feeding monitoring system and method for material tape of 3D printer

A 3D printer and monitoring system technology, applied in the direction of liquid material additive processing, processing and manufacturing, manufacturing auxiliary devices, etc., can solve problems that affect printing accuracy, poor discharge of printer nozzles, and product defects, etc., to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

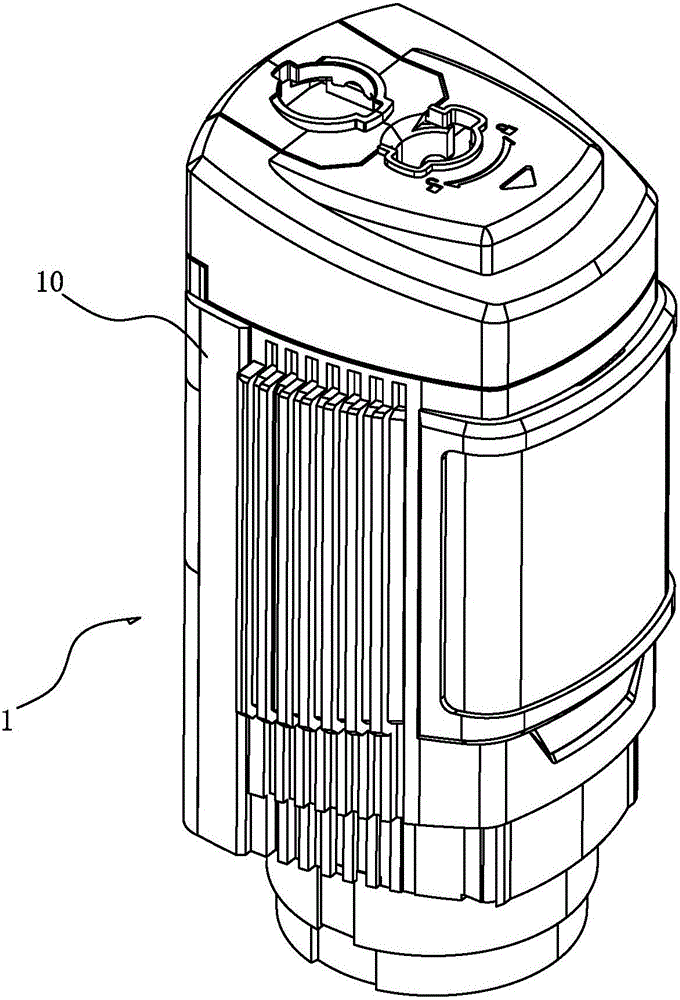

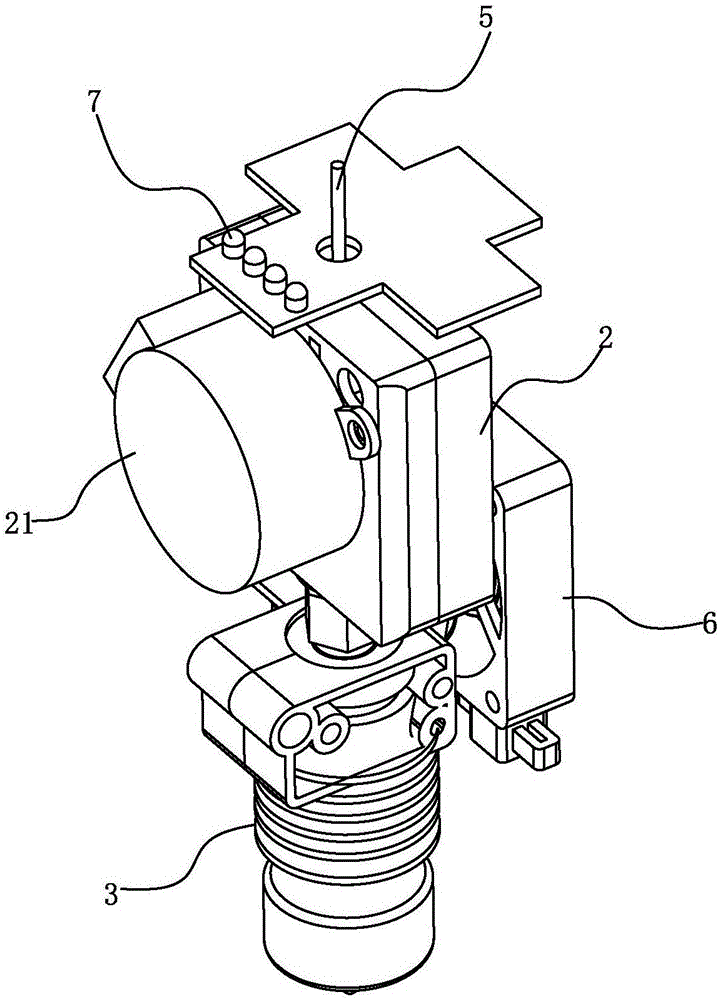

[0036] The solution adopted in Embodiment 1 of the present invention is to integrate the monitoring system inside the print head 1 . See Figure 2-Figure 5 As shown, the print head 1 has a housing 10 , and a feeding mechanism 2 and a heating unit 3 are installed in the housing 10 from top to bottom, and the feeding mechanism 2 and the heating unit 3 are connected by a feeding tube 30 . The material tape 5 enters the feeding mechanism 2 from the entrance of the upper end of the housing 10 of the print head 1, and the material tape 5 is pushed downward through the feeding mechanism 2. It is heated to become a molten state. When the subsequent strip 5 continues to enter the heating unit 3, it will squeeze the raw material in the heating unit 3, so that the molten raw material is extruded from the nozzle 31 below the heating unit 3.

[0037] The monitoring system in the present embodiment 1 includes a sensor 4, and the sensor 4 is arranged above the feeding end of the feeding mec...

Embodiment 2

[0049] See Figure 7 It is a structural schematic diagram of Embodiment 2 of the present invention. The difference between the second embodiment and the first embodiment is that in the second embodiment, the feeding mechanism 2 includes two sets of feeding wheels, and the driving wheels 24 of the two sets of feeding wheels are simultaneously linked with the motor 21 . Meanwhile, the sensor 4 in the second embodiment is arranged below the discharge end of the feeding mechanism 2 and above the heating unit 3 .

[0050] In order to ensure the accuracy of feeding and prevent errors in the feeding mechanism, the second embodiment is provided with two sets of feeding wheels, which also include a driving wheel 24 and a driven wheel 25 driven by a motor 21 . The difference from the first embodiment is that in the second embodiment, the two driving wheels 24 both use gears, while the driven wheel 25 uses a friction wheel with a trough. The two driving wheels 24 adopt duplex gears, an...

Embodiment 3

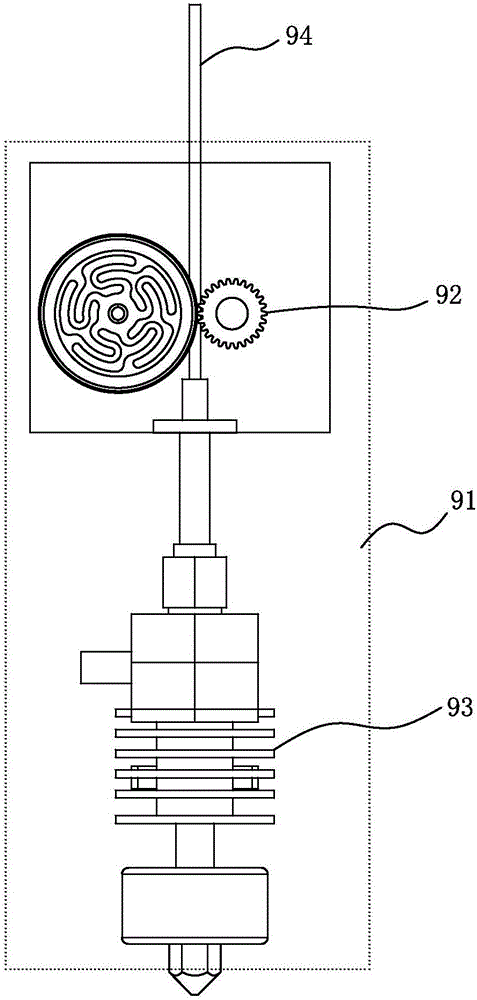

[0054] The third embodiment differs from the first and second embodiments in that: in the third embodiment, the heating unit 3 is arranged inside the print head 1 of the printer, and the feeding mechanism 2 is located outside the print head 1 . According to the first and second embodiments, the sensor 4 can be set in the print head 1 or in the feeding mechanism 2 . Certainly the best way is to be arranged in the feeding mechanism 2, so that when the material tape 5 is used up, the sensor 4 can monitor this situation in time. When the sensor 4 is arranged in the feeding mechanism 2, the sensor 4 can be arranged above the feeding end of the feeding mechanism 2, and can also be arranged below the discharging end of the feeding mechanism. If feeding mechanism 2 adopts multiple sets of feed wheel sets, it can also be arranged between the gift-giving wheel sets.

[0055] In summary, the feeding monitoring method of the material tape adopted in the present invention is to monitor th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com