Motor stator winding machine capable of limiting, shaping and sliding

A motor stator and winding machine technology, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problems of inconvenient and stable sliding winding, inconvenient copper wire limit traction, etc., and achieve easy winding The effect of working and avoiding breakage or bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

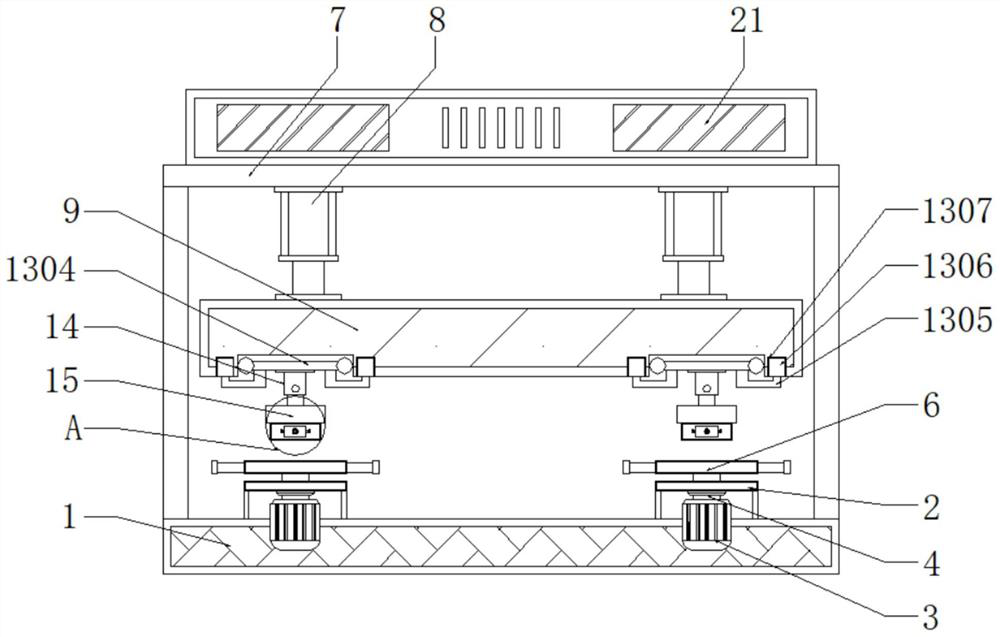

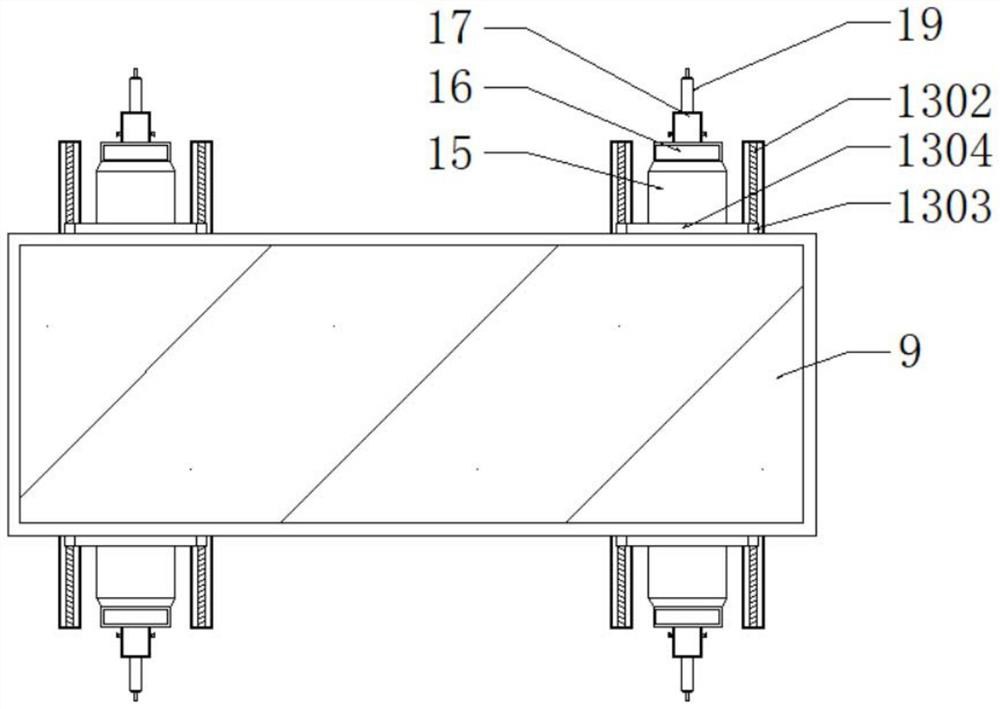

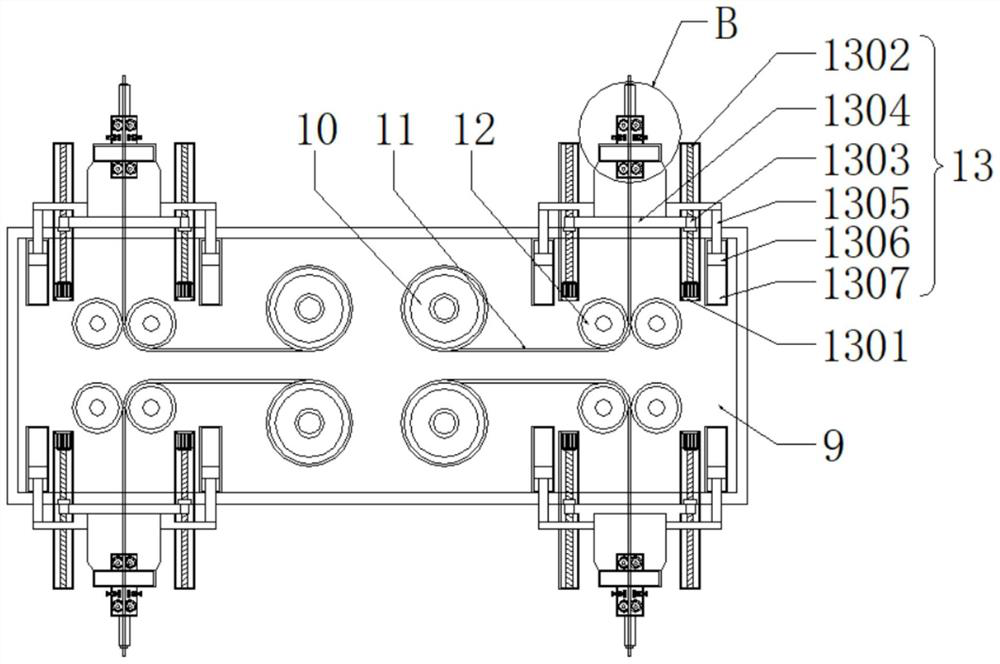

[0031] see Figure 1 to Figure 8 , the present invention provides a technical solution: a motor stator winding machine with position-limiting and shaping sliding, including a workbench 1, a lifting frame 9 and a moving assembly 13, an upper frame 7 is fixed on the upper outer side of the workbench 1, and the upper frame A cylinder 8 is installed under the inside of 7, and the lift frame 9 is arranged on the lower side of the hydraulic rod of the cylinder 8, and a winding roller 10 is arranged under the inside of the lift frame 9, and a copper wire 11 is arranged on the outside of the winding roller 10, and the lift frame 9 9 is provided with wire rollers 12 on the lower side of the inside, and the moving assembly 13 is arranged on the lower, front and rear sides of the lifting frame 9, and the moving assembly 13 includes a driving motor 1301, a screw mandrel 1302, a threaded sleeve 1303, a horizontal plate 1304, and a connecting rod. 1305, slider 1306 and chute 1307, a screw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com